Power device for driving lens barrel of projection lens group to rotate

A technology of projection lens and power device, which is applied in signal devices, lighting devices, components of lighting devices, etc., and can solve the problems of long overall length and loud noise of geared motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

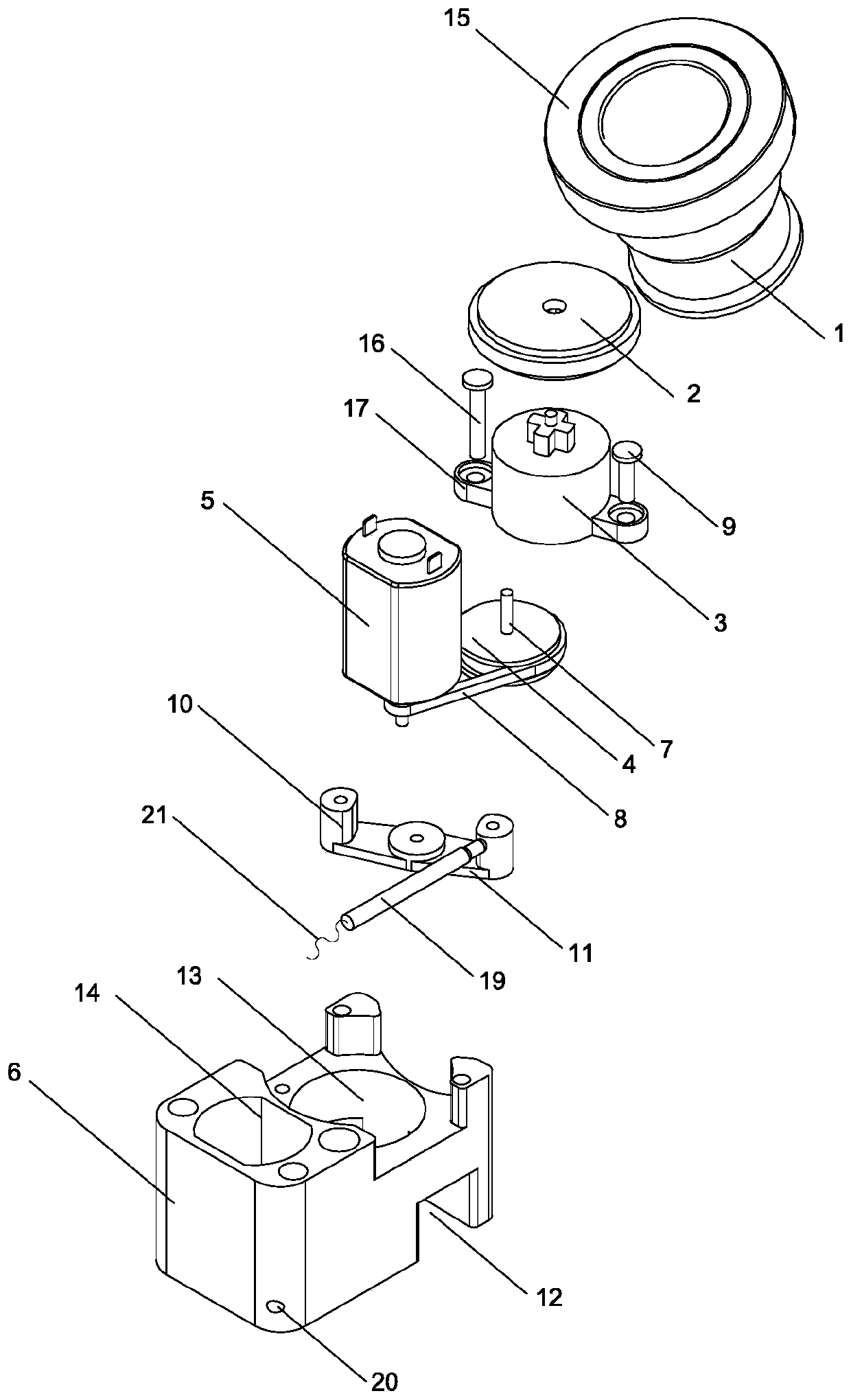

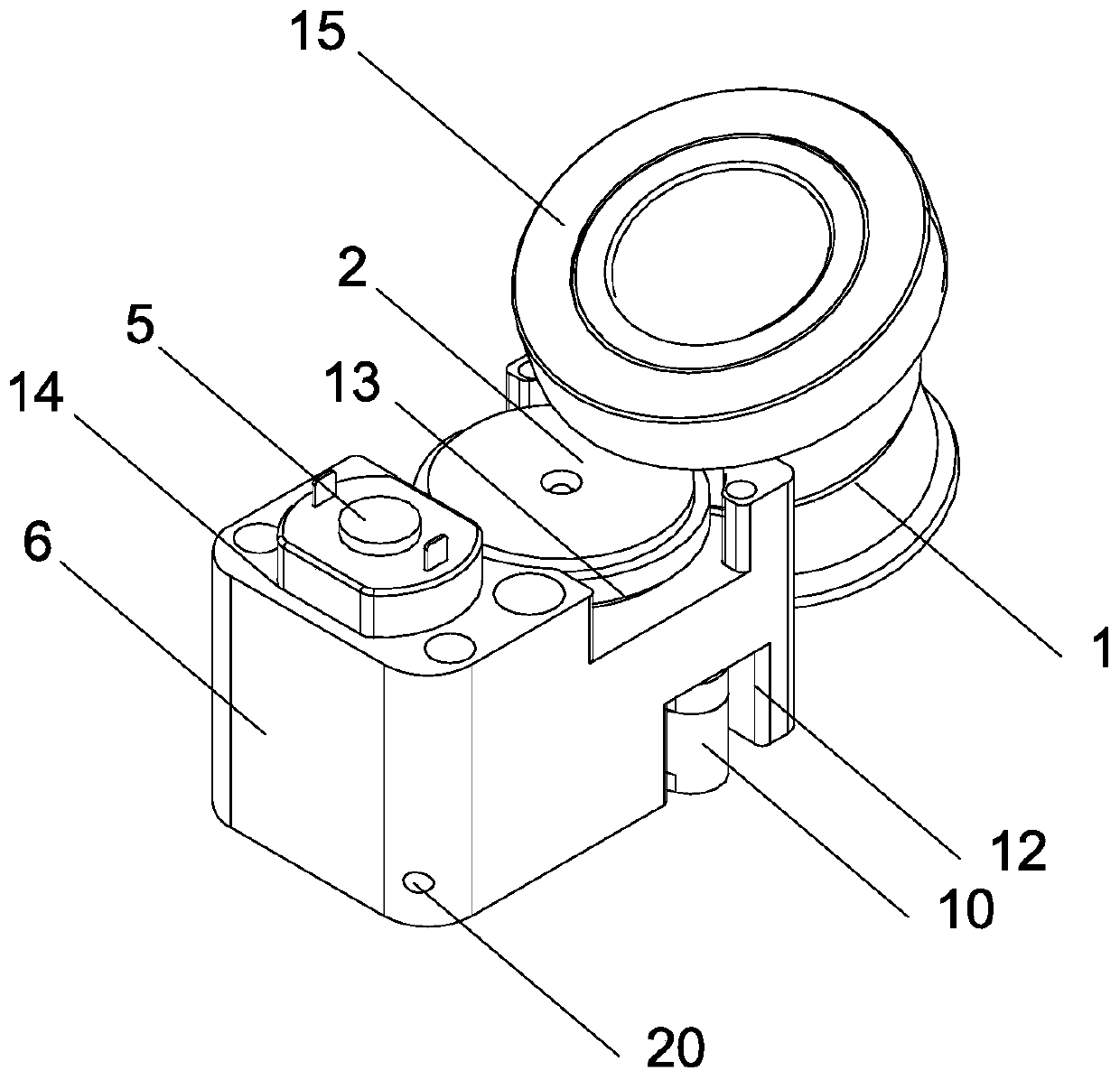

[0025] see figure 1 , figure 1 It is a schematic diagram of the structural principle of the first preferred embodiment of a power device for driving the rotation of the lens barrel of the projection lens group in the present invention. Such as figure 1 As shown, the power device used to drive the rotation of the projection lens group lens barrel in this embodiment includes a projection rotation device, a coupling rubber wheel 2, a planetary gear reduction box 3 with a planetary gear set inside, a pulley 4, a DC motor 5, The transmission structure fixed bracket 6, the first installation groove 13 and the second installation groove 14 placed on the transmission structure fixed bracket 6 for installing the planetary gear reducer 3 and the DC motor 5 respectively, are used to connect the DC motor 5 motor shaft The belt 8 of the pulley 4, the pulley fixed bracket, the third installation groove 12 for installing the pulley fixed bracket placed at the bottom of the transmission str...

Embodiment 2

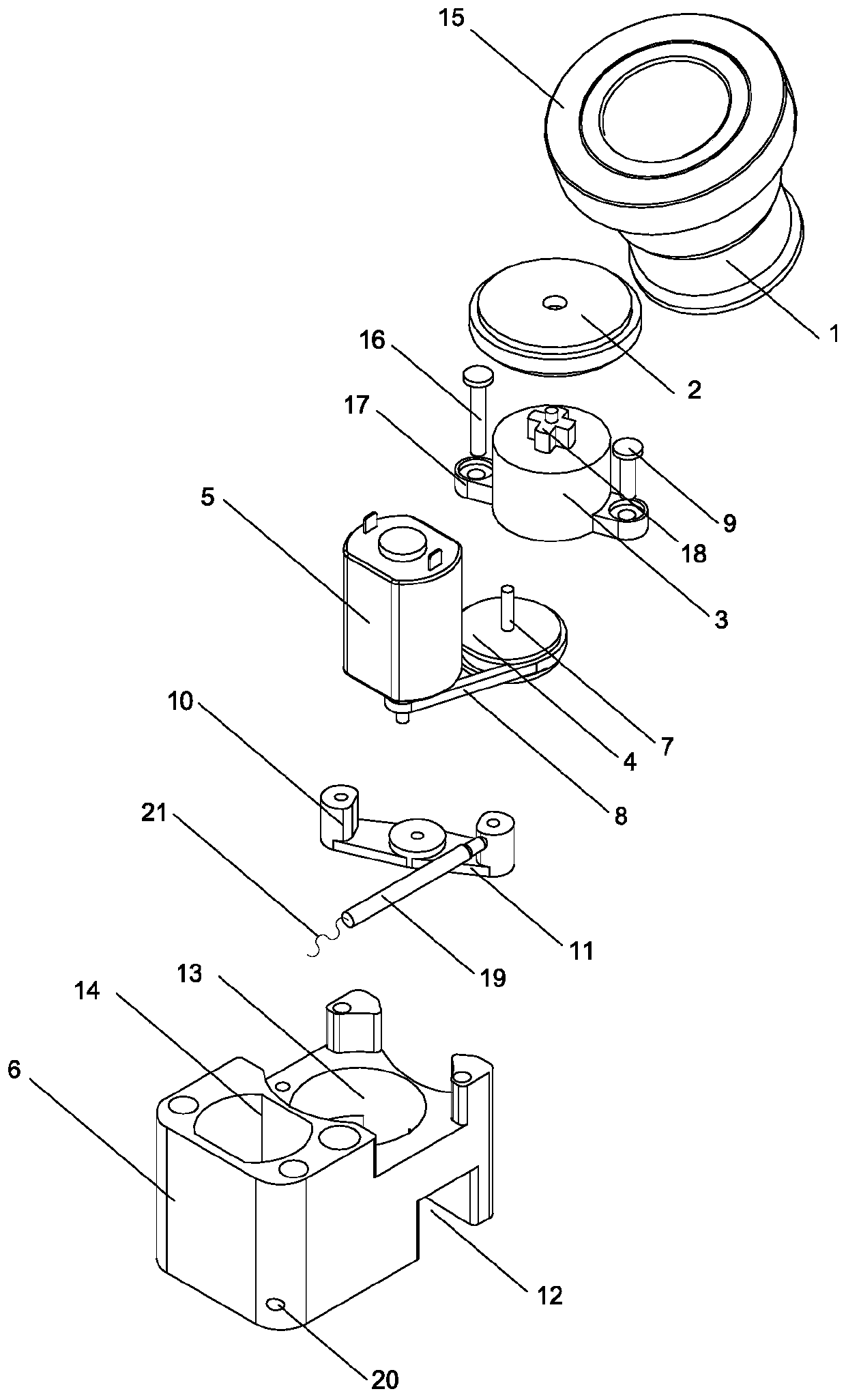

[0047] see figure 2 , figure 2 It is a schematic diagram of the structure principle of the second preferred embodiment of the power device for driving the rotation of the lens barrel of the projection lens group. in, figure 2 The power unit shown for driving the rotation of the lens barrel of the projection lens group is composed of figure 1 The power device shown for driving the rotation of the lens barrel of the projection lens group is optimized.

[0048] and figure 1 Compared with the power device used to drive the rotation of the lens barrel of the projection lens group shown, figure 2 The top of the planetary gear reduction box 3 for driving the rotation of the projection lens group lens barrel is provided with a cross-shaped gear shaft 18, and the bottom end of the coupling rubber wheel 2 is provided with a cross-shaped groove meshing with the cross-shaped gear shaft 18. The belt pulley center shaft 7 is connected with the cross-shaped groove and the coupling r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com