A low-noise venting method for reactor nitrogen replacement

A nitrogen replacement, reaction kettle technology, applied in chemical/physical/physical-chemical stationary reactors, inert gas generation, control/regulation processes, etc., can solve problems such as tinnitus, loud noise, and the inability of staff to concentrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

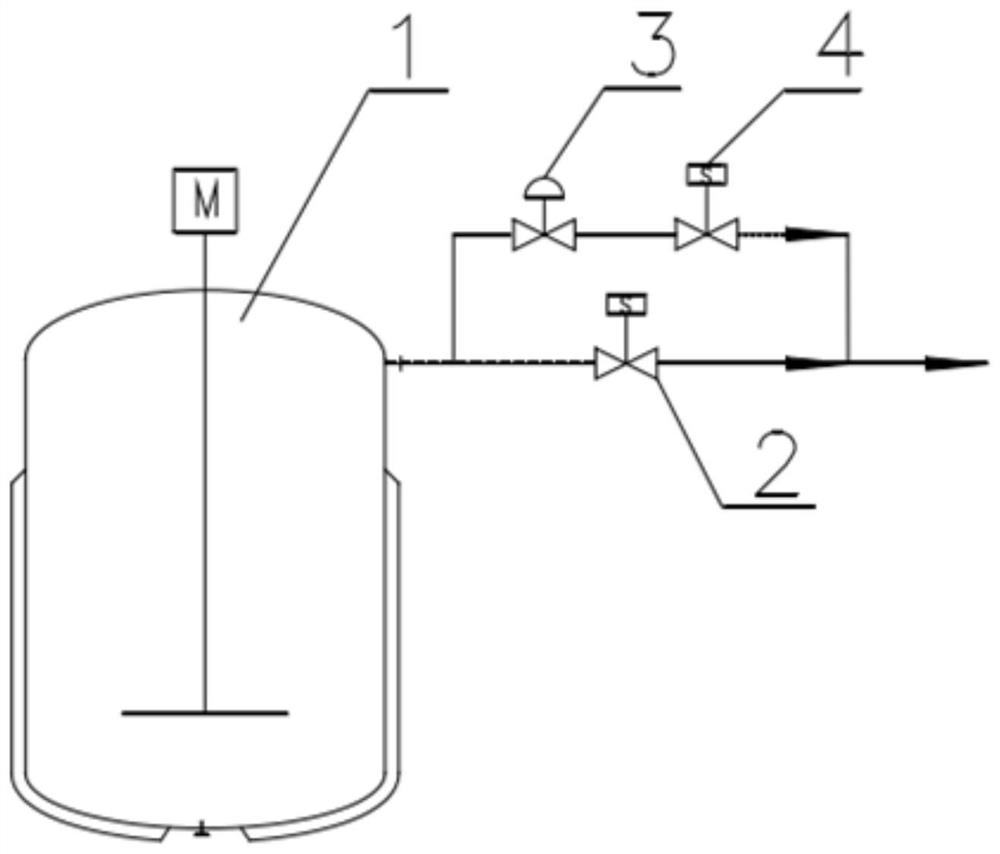

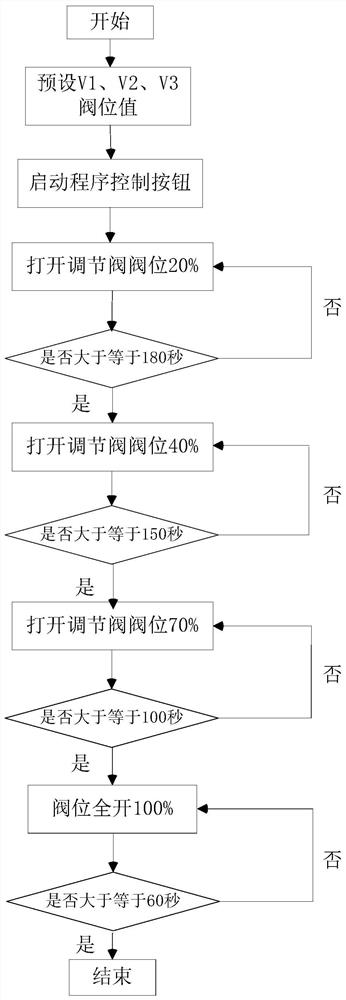

Method used

Image

Examples

Embodiment 2

[0034] The difference between embodiment 2 and implementation 1 is that the valve positions of the two self-defined variable regulating valves V1 and V2 are preset at 30% and 70%, and after the automatic program control venting stage, the venting time interval of each step is a certain value . During the whole process, the noise meter showed that the noise was 60-80dB.

Embodiment 3

[0035] The difference between embodiment 3 and implementation 1 is that the valve positions of the four self-defined variable regulating valves V1, V2, V3, and V4 are preset at 10%, 30%, 50%, and 80%. The emptying time interval of each step is a certain value. The noise meter during the whole process showed that the noise was 50-60dB, but the whole process took a long time.

[0036] In the above-mentioned embodiments, the value of the valve position of each step, the number of steps, and the time of venting are all reference values, which can be controlled according to experience. Relationship.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com