Magnetic pump

A technology of magnetic pump and pump cover, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of adverse effects, high temperature of transmission medium, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

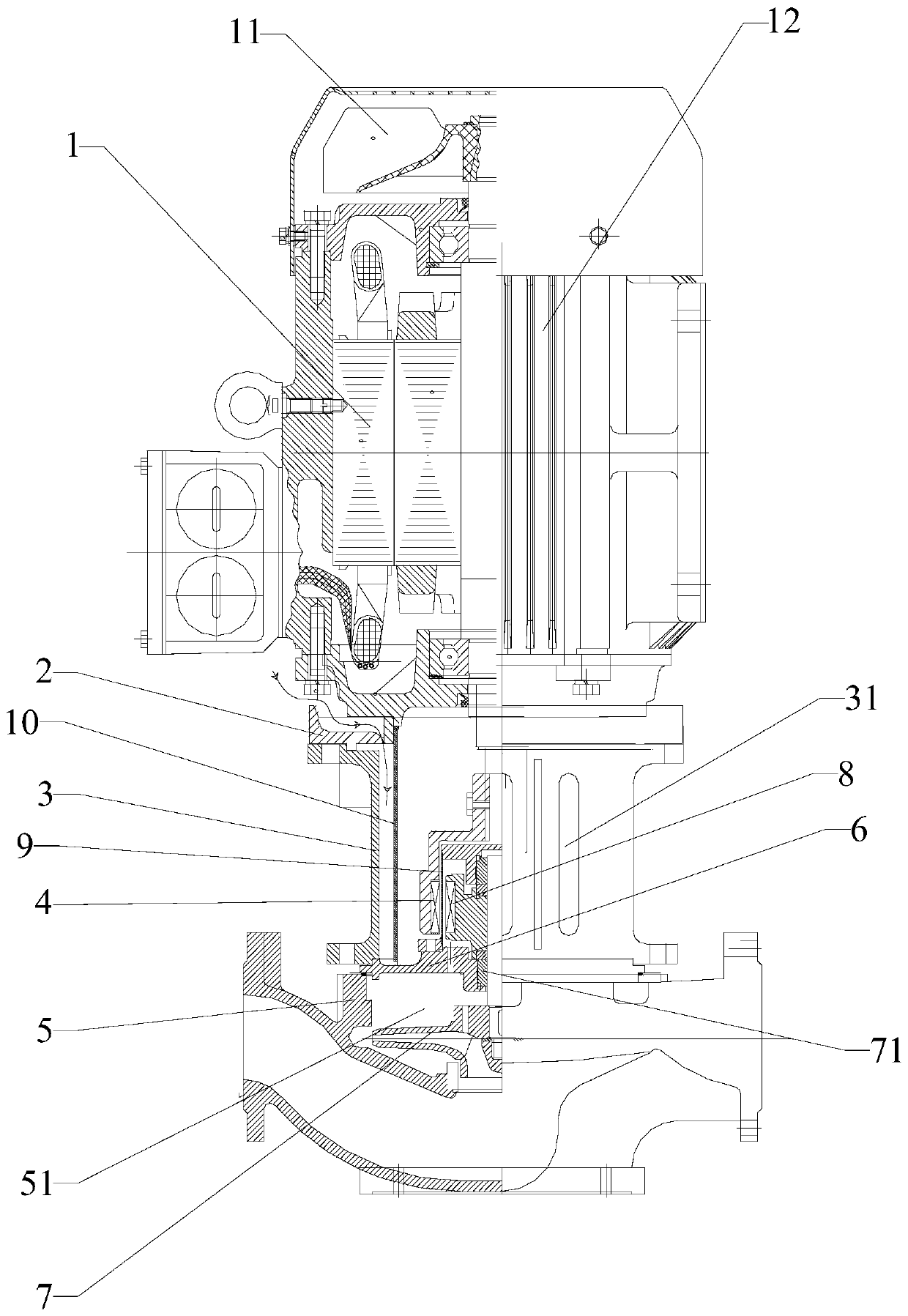

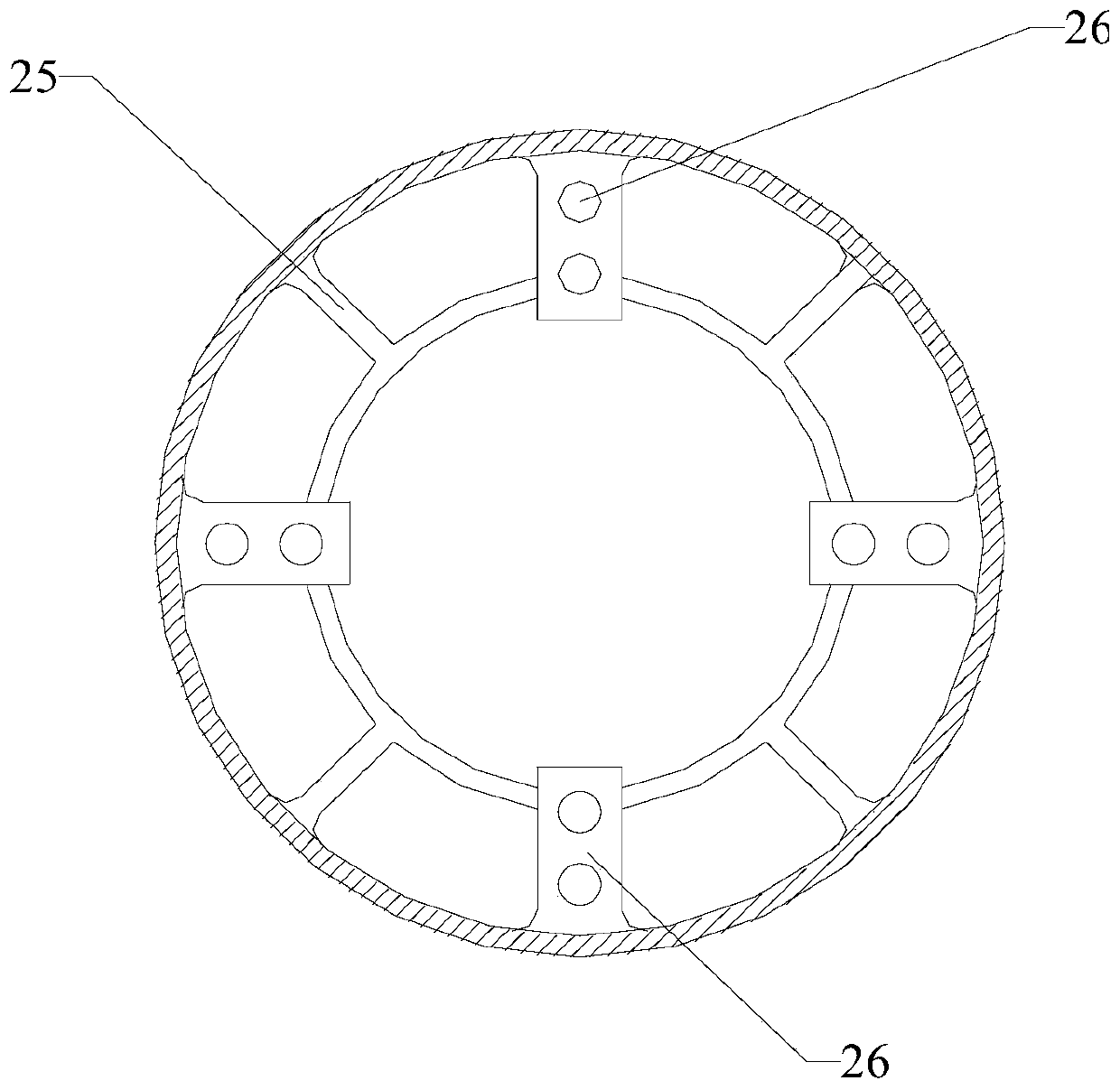

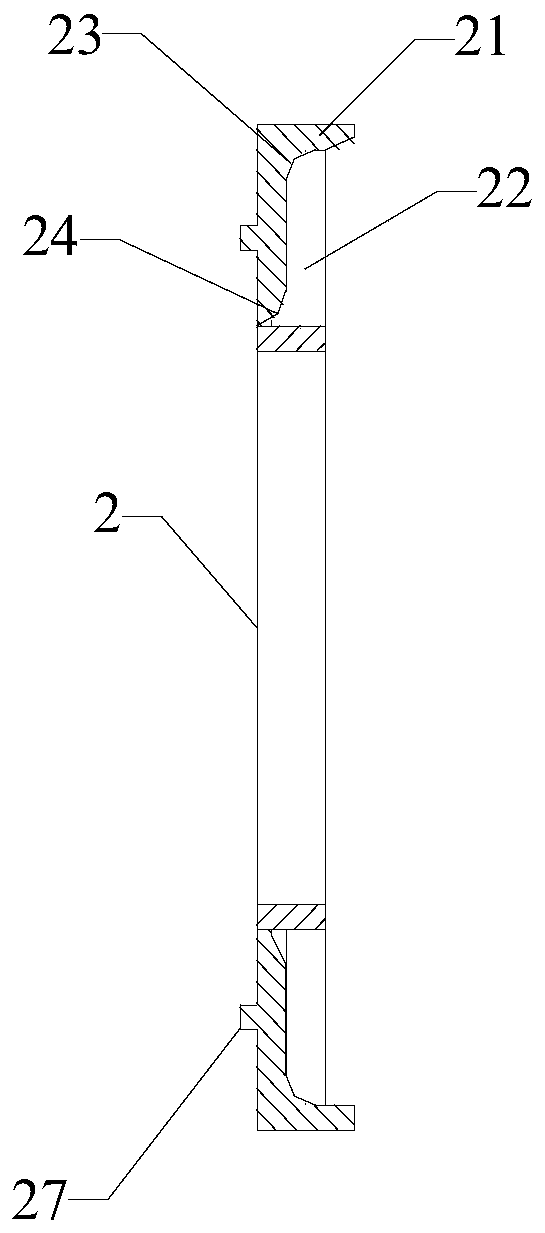

[0042]A magnetic pump, comprising a motor 1, an air guide disk 2, a support 3, an outer magnet 4, a spacer 10, a pump body 5, a pump cover 6, an impeller 7, a rotor 8 and a spacer 9; the outer magnet 4 Connected to the shaft end of the motor 1, the pump cover 6 is sealingly connected with the pump body 5 to form a pump chamber 51, the pump cover 6 is pierced with a rotating shaft 71, and the impeller 7 is connected to the shaft 71 located in the pump chamber 51 At one end, the rotor 8 is connected to the rotating shaft 71, the rotor 8 is located outside the pump chamber 51, and the spacer sleeve 9 is connected to the side of the pump cover 6 away from the pump chamber 51, so that the rotor 8 is sealed and isolated between the pump cover 6 and the pump chamber 51. In the sealed cavity formed by the isolation sleeve 9, the outer magnet 4 is suspended and sleeved outside the isolation sleeve 9; the bracket 3 is suspended and sleeved outside the outer magnet 4, and one end of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com