Ultra-large self-propelled tunnel multifunctional operation platform and construction method of tunnel steel bar waterproof plate

A working platform, multi-functional technology, applied in tunnels, tunnel lining, earth drilling and mining, etc., can solve the problems of time-consuming and laborious processing and manufacturing costs, large number of input platforms, and difficulty in tunnel assembly, so as to reduce the difficulty of lifting and ensure stability. The effect of reducing labor input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

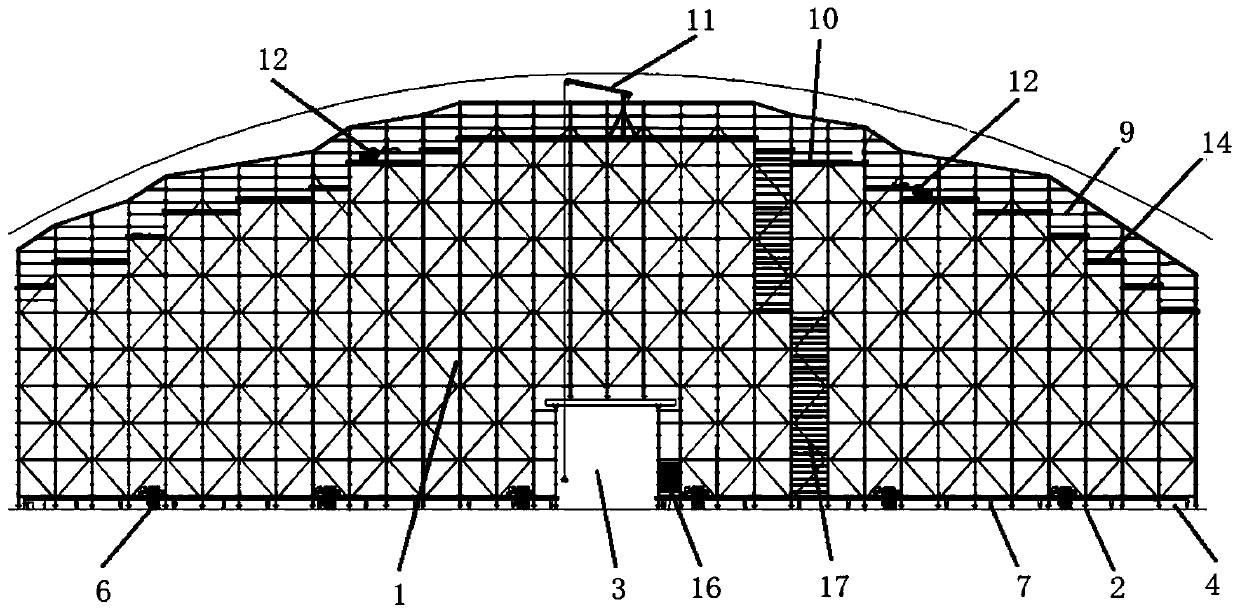

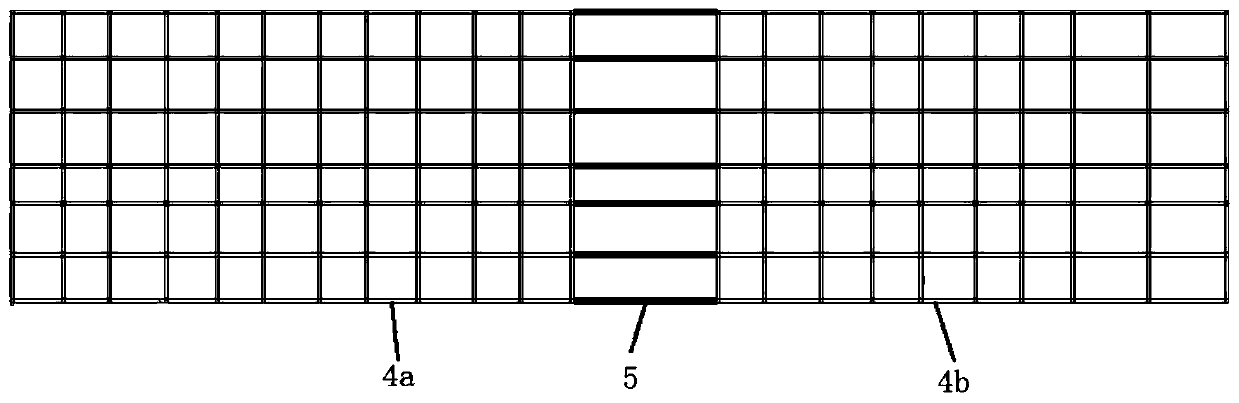

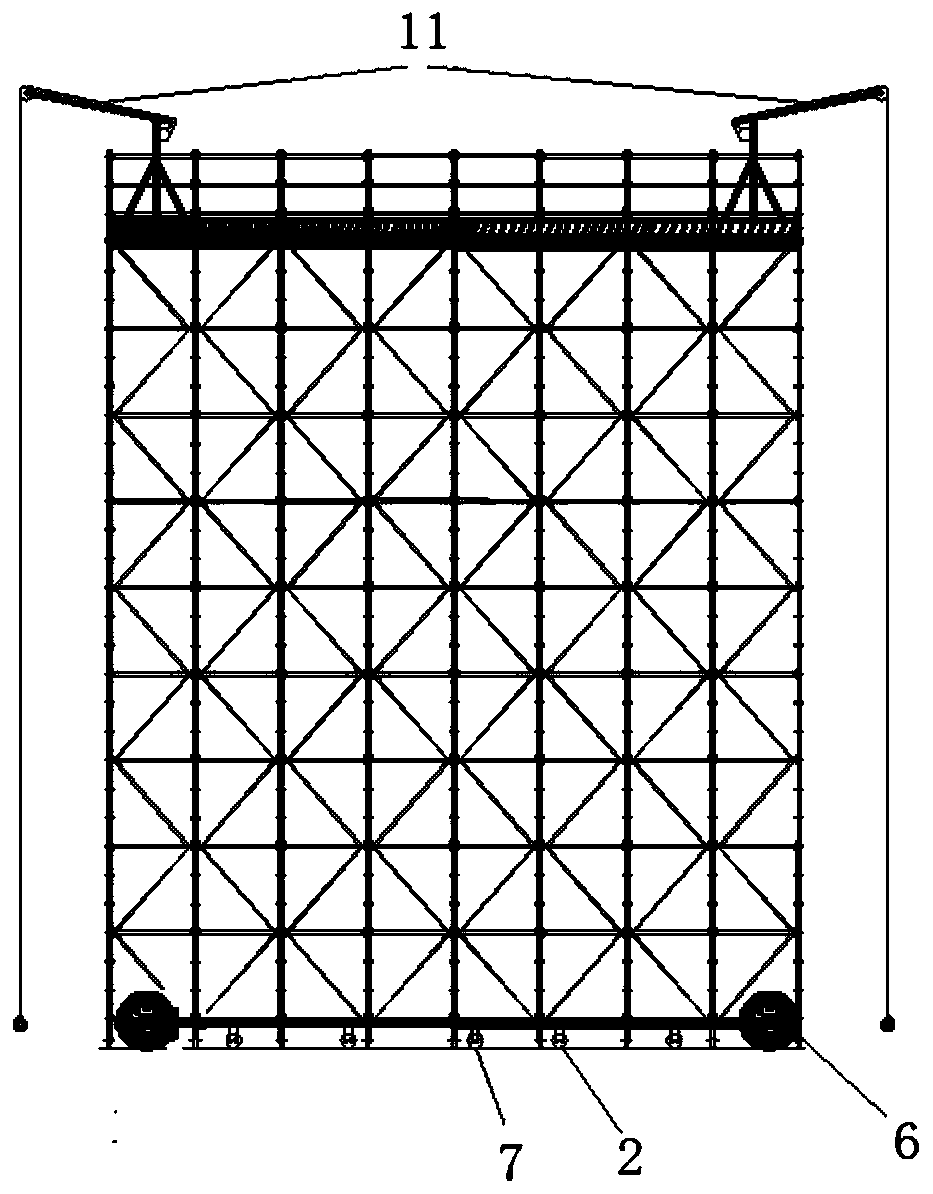

[0032] combine figure 1 — Figure 5 As shown, a super-large self-propelled tunnel multifunctional work platform is mainly composed of a buckle bracket 1, an adjustable base 2, a passing door opening 3, a chassis 4, a temporary intermediate frame 5, a driving wheel 6, and a supporting roller 7. Drive motor 8, railing 9, work platform 10, cantilever crane 11, winch 12, drum 13, skirting board 14, wheel axle pressing mechanism 15 form.

[0033] The main body of the pan buckle support 1 is formed by lapping of vertical rods, horizontal rods, and oblique rods. The horizontal and vertical forces are better, strong and firm, the safety of workers is guaranteed, and the assembly and disassembly are simple and easy to learn. Buckles are generally rented, and the amount of section steel is not much. Generally, outsourcing processing is not required. The manufactu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com