A variable flow pulse hydraulic fracturing method

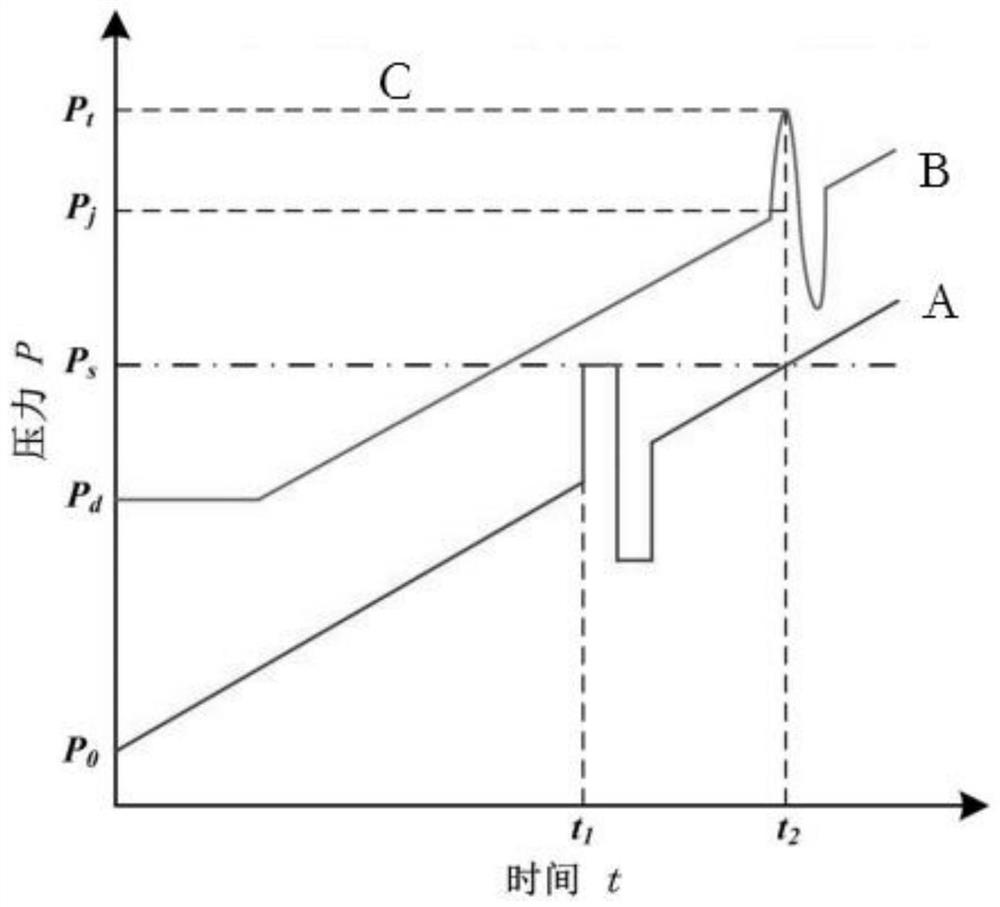

A hydraulic fracturing and variable flow technology, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problem of prolonged operation time, construction technology and parameter design method of pulse injection flow rate, and equipment reliability. It can reduce the time cost, improve the fracturing effect, and save the operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0063] Step 1. The fracturing operation reservoir is located 2000m underground, the fracture strength of the rock is 110MPa, and the safety limit pressure of the wellhead equipment is P S is 75MPa. After the fracturing construction site equipment and personnel are ready, the conventional constant injection flow rate Q 0 3m 3 / min for fracturing operation, injection time t 2 After 13.6217s, the wellhead pressure is close to the ultimate pressure, while the bottom hole pressure is only 98.1MPa, which is far less than the fracture strength of the rock, and the operation cannot be continued. At this time, stop the injection, confirm the stop injection time, and restore the wellhead pressure to the level before the injection state.

[0064] Step 2. According to the property parameters of the pipe string and fracturing fluid, the propagation speed C of the pressure wave is calculated as 969 m / s by the following formula.

[0065]

[0066] In the formula: E is the elastic modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com