A prefabricated functional well for water supply and drainage engineering

A drainage engineering and prefabricated technology, applied in water conservancy engineering, infrastructure engineering, artificial islands, etc., can solve the problems of polluted functional well soil environment, poor connection sealing, etc., to achieve good sealing effect, increase sealing, and improve connection strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

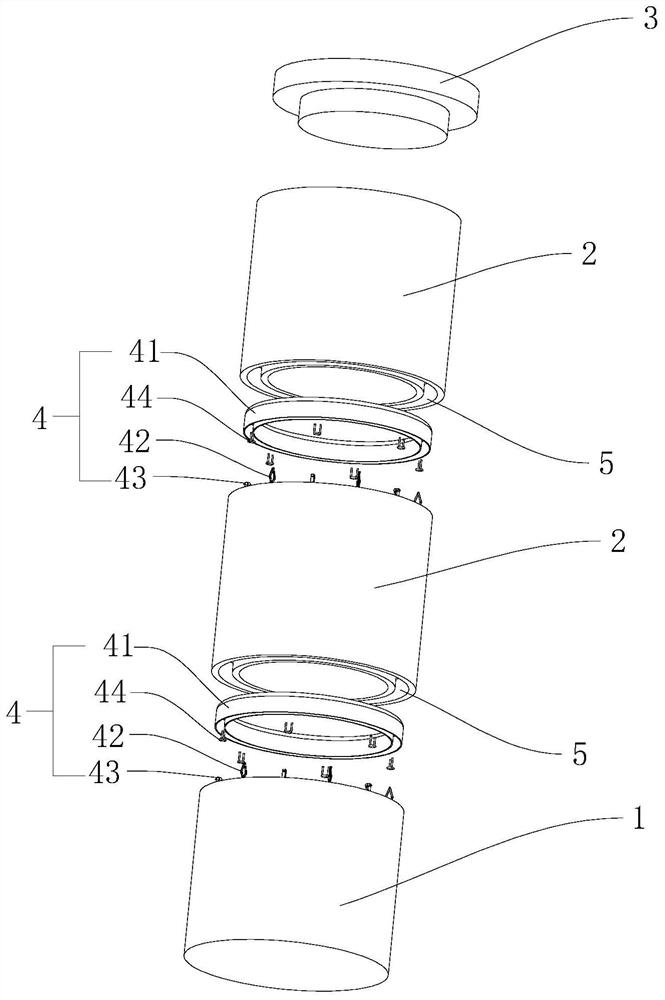

[0033] refer to figure 1 , is a prefabricated functional well for water supply and drainage engineering disclosed by the present invention, which includes a well base 1, a well body 2 and a well cover 3 in sequence from bottom to top. There are two well bodies 2, and the well base 1, well body 2 and well cover The central axes of 3 coincide with each other, and the inner diameter and outer diameter of the well base 1 and the well body 2 are the same.

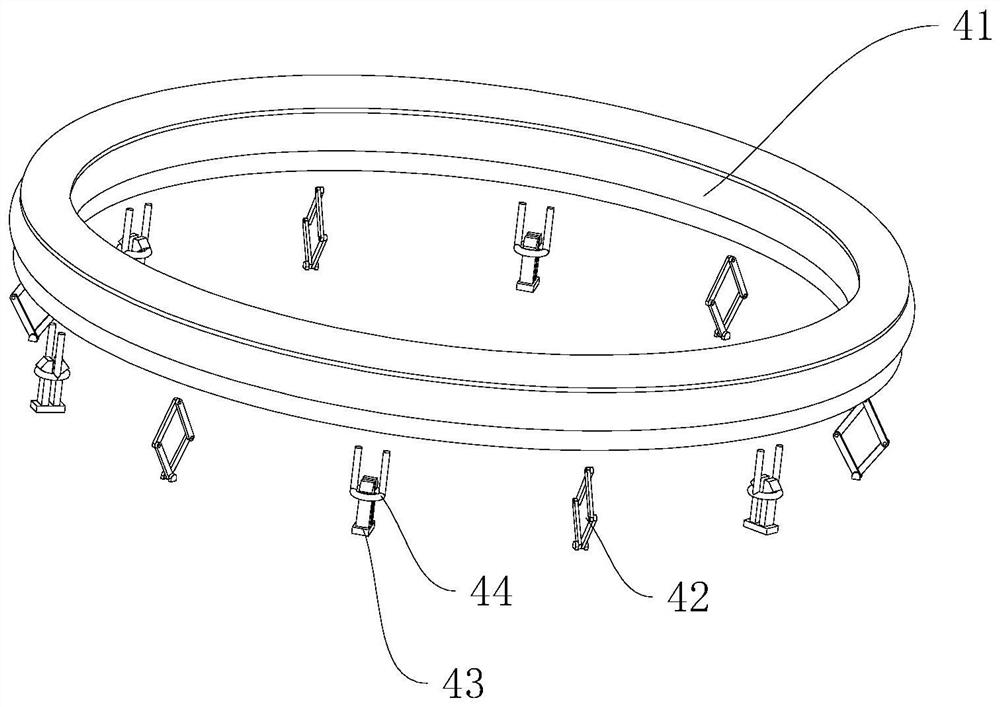

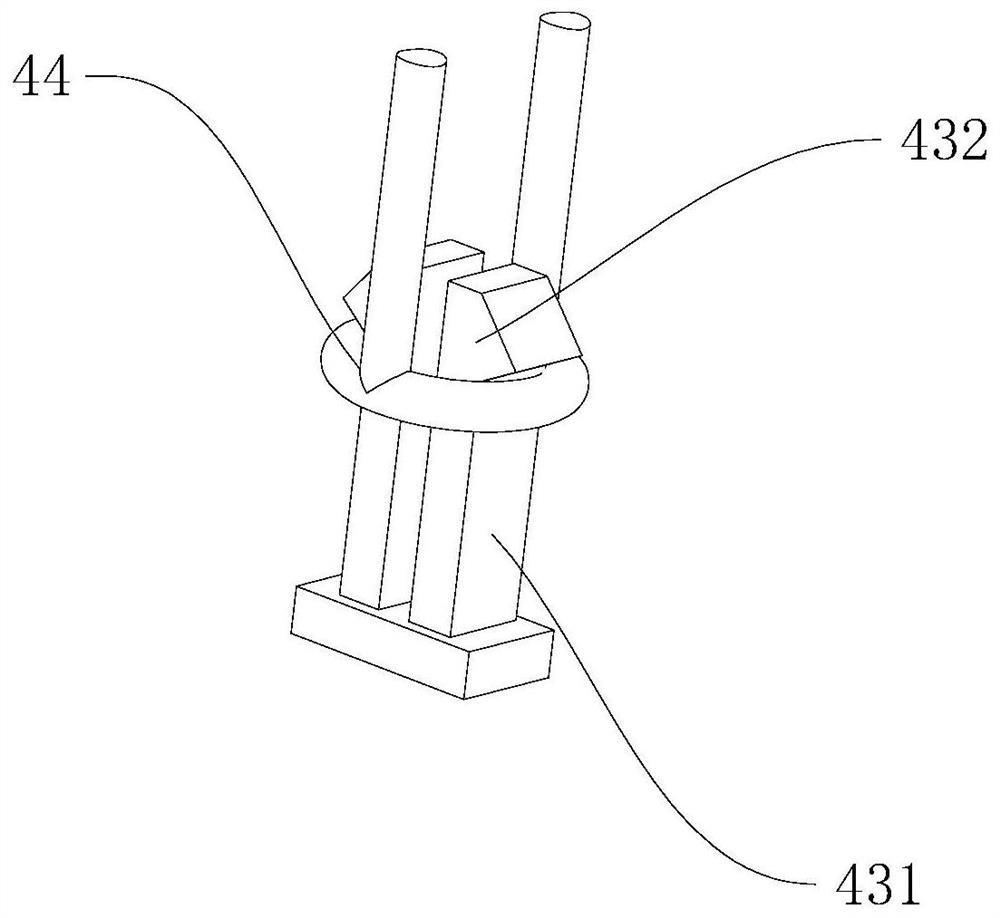

[0034] combine figure 1 and figure 2 It can be seen that the end surface of the well block 1 facing the well body 2 and the end face of the well body 2 facing away from the well block 1 are integrally formed with annular flexible bumps 4, and the end face of the well body 2 facing the well block 1 is provided with end-to-end connections. The placement groove 5, the annular flexible protrusion 4 is inserted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com