A weaving method for hollow weave without floating thread

A weaving and floating thread technology, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems of fabric damage, floating thread is not easy to be too long, and floating thread is easy to be snagged, so as to achieve high loop density and not easy to snag The effect of smooth and beautiful yarn and cloth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

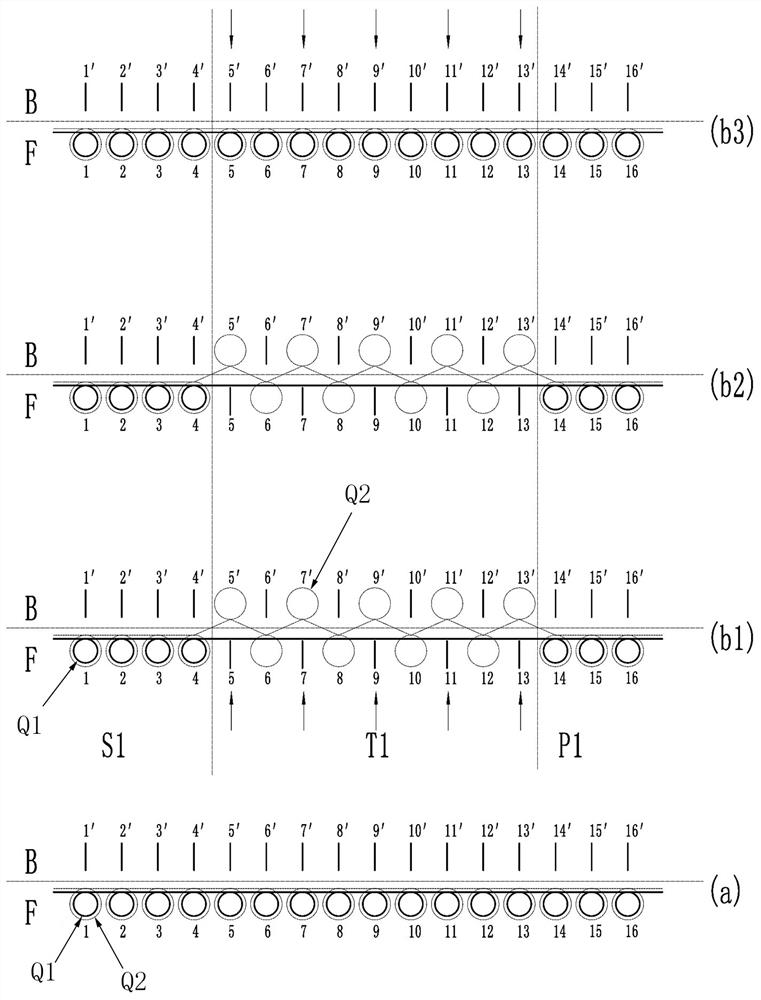

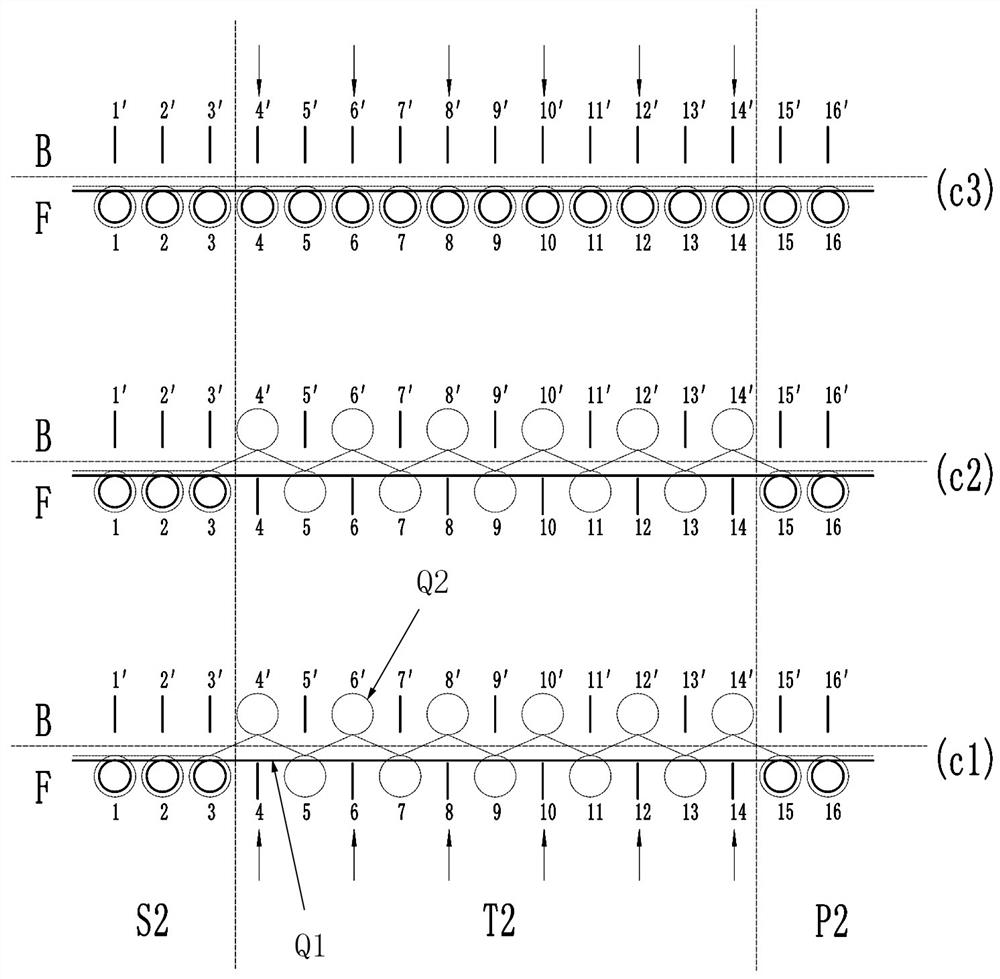

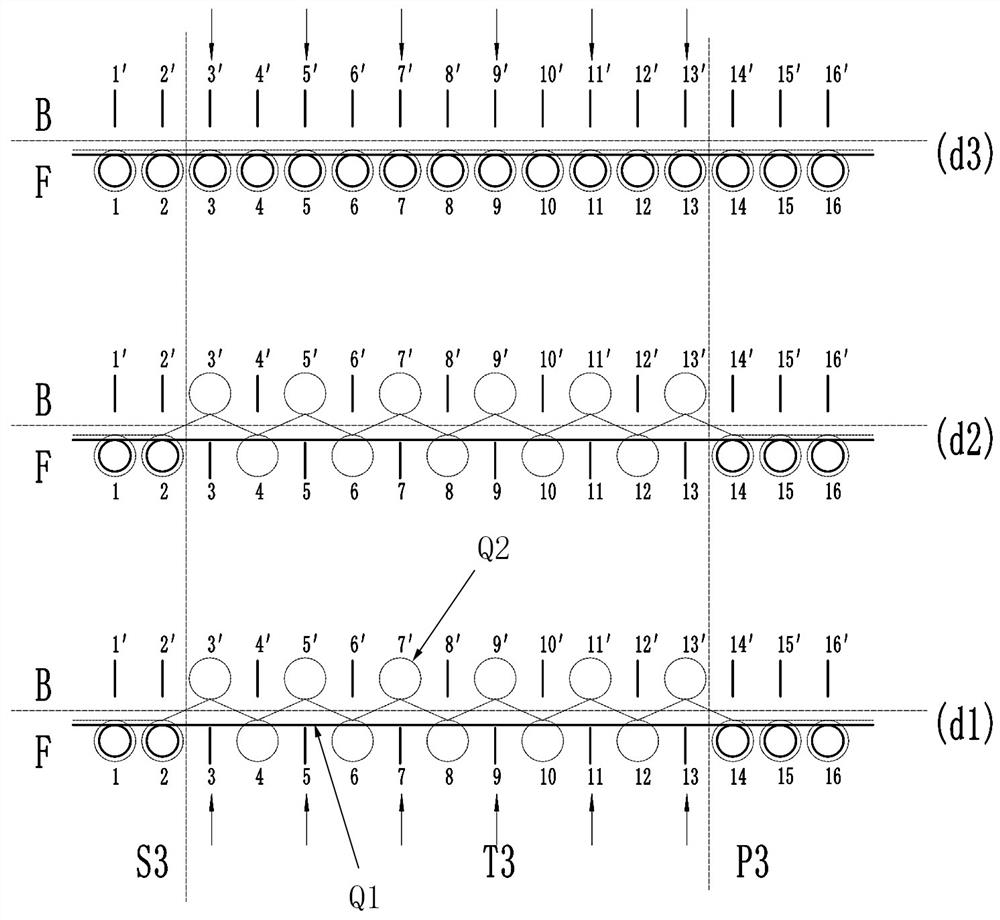

[0022]See the accompanying drawings. The woven method described in this example has more than three knitting systems with three or more knitting systems at least with a pair of needles, and the two yarns supply the yarn, one of which is supplied to the main yarn Q1. A small yarn Q2 is supplied;

[0023]In the left and right, the front needle bed is referred to, with 16-pin as an example, the front bed needle is indicated by 1-16 from left to right, and the rear bed needle is expressed by 1'-16 'from left to right;

[0024]Such asfigure 1 (a), when the initial state, the head stops on the left side, the front needle bed is a full state, and the rear needle is an empty needle state;

[0025]1)figure 1 As shown in (B1), the 1 to 4 needle regions are set to the first non-hollow regions S1, 5 to 13 needle regions to be set to the hollow region T1, 14 to 16 needle region to be set to the second non-hollow region P1;

[0026]Row, the first woven system, the first braided system, the coil of the hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com