Fermentation tank with defoaming function

A fermentation tank and defoaming technology, applied in the field of fermentation, can solve the problems of contaminated bacteria, product loss, liquid escape, etc., and achieve the effect of improving the defoaming effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

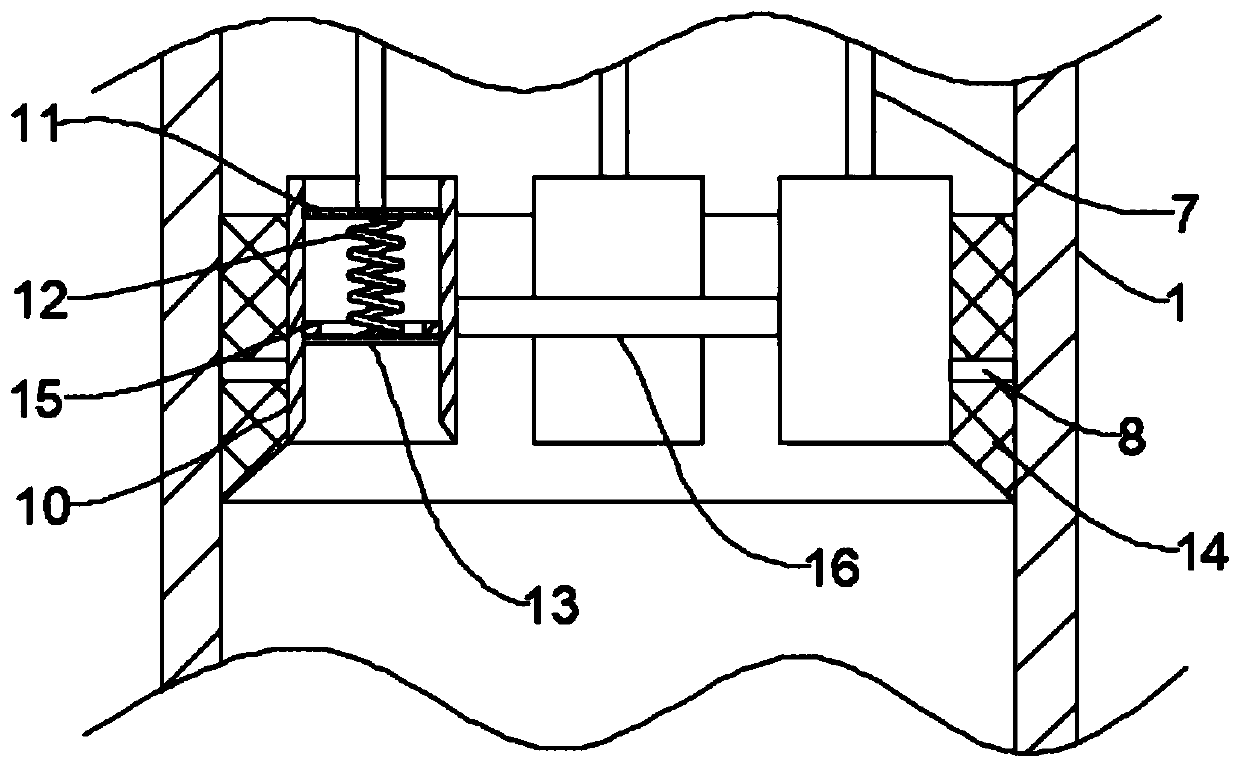

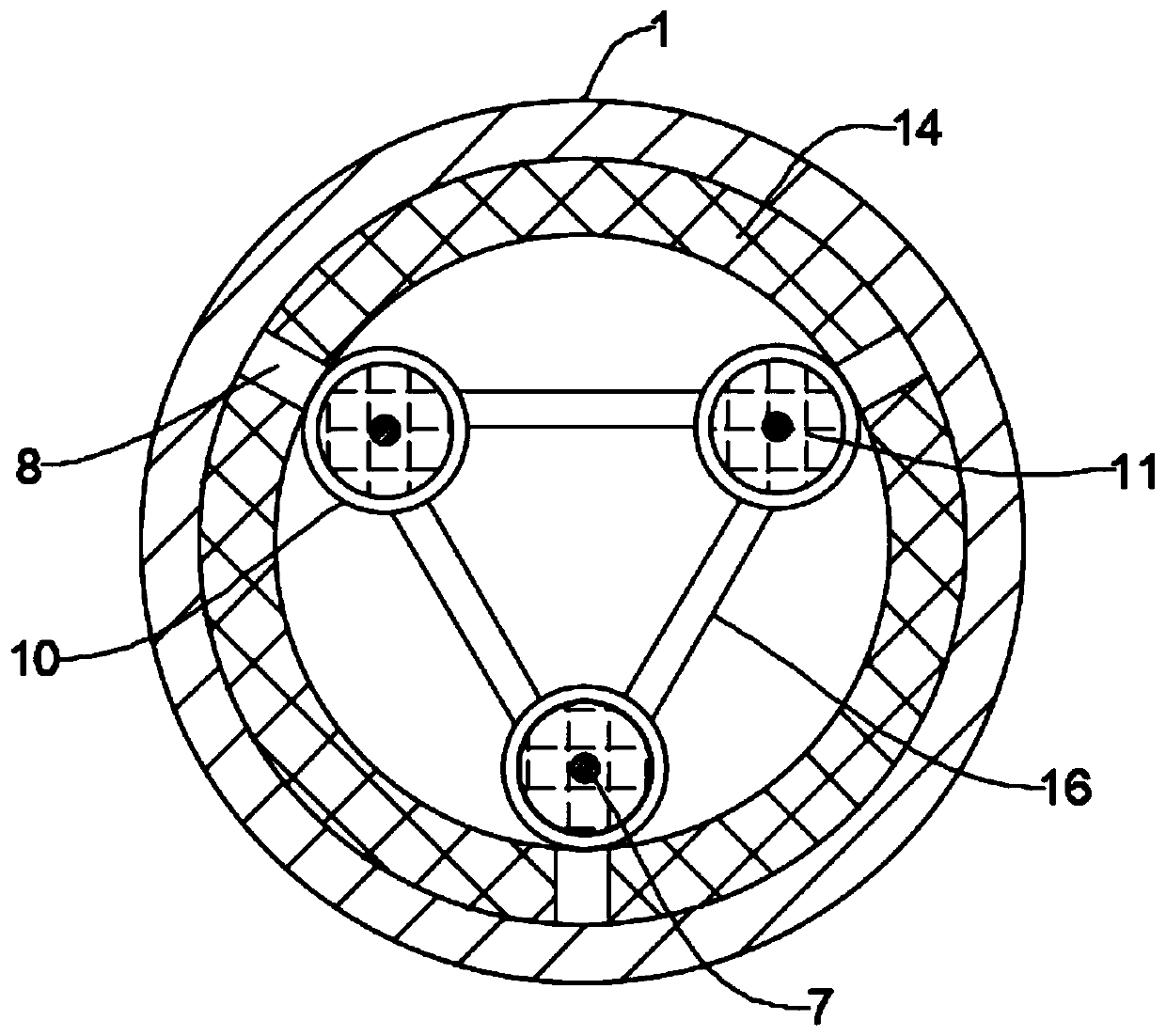

[0025] Such as Figure 1-3 As shown, a fermenter with defoaming function includes a tank body 1, a plurality of columns 2 are fixedly connected to the bottom of the tank body 1, the tank body 1 is supported by the columns 2, and the side wall of the tank body 1 is provided with an air outlet 3. The bottom of the tank body 1 is provided with a discharge port 4, and the top of the tank body 1 is fixedly connected with a feed channel 5. The feed channel 5 is opened and closed by a solenoid valve. In the closed state, it is airtight. There is a control panel 6 slidingly connected to the inner wall of the tank body 1 and the feed channel 5. The cross section of the control panel 6 is a circular structure. The inner wall of the tank body 1 is fixedly connected with a plurality of horizontally arranged fixed rods 8, and the other end of the fixed rods 8 is fixedly connected with a defoamer 9. The defoamer 9 includes a sleeve 10, and the sleeve 10 is provided with a The control rod 7...

Embodiment 2

[0033] Such as Figure 4-5 Shown, the difference between this embodiment and embodiment 1 is:

[0034]The side wall of the sleeve 10 is provided with an opening 17 connected to the bottom end of the filter screen 14, and the air bubbles will enter between the upper slide plate 11 and the lower slide plate 13 along the filter screen 14 from the opening 17, and then move upward on the control plate 6. The bottom of the sleeve 10 is fixedly connected with a defoaming plate 18. The defoaming plate 18 is provided with multiple groups of defoaming holes 19. The defoaming holes 19 are composed of channels that gradually become larger from top to bottom and communicate with each other. , during the upward movement of the control board 6, the control board 6 will drive the upper slide 11 to move upward through the control rod 7, and the upper slide 11 will drive the lower slide 13 to move upward through the spring 12, and the upward movement of the lower slide 13 will be in line with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com