Synthetic process of dexmedetomidine hydrochloride

A technology of dexmedetomidine hydrochloride and dexmedetomidine, which is applied in the field of drug synthesis, can solve the problems of complex reaction operation and low total yield of the process, and achieve the effect of simple operation and controllable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

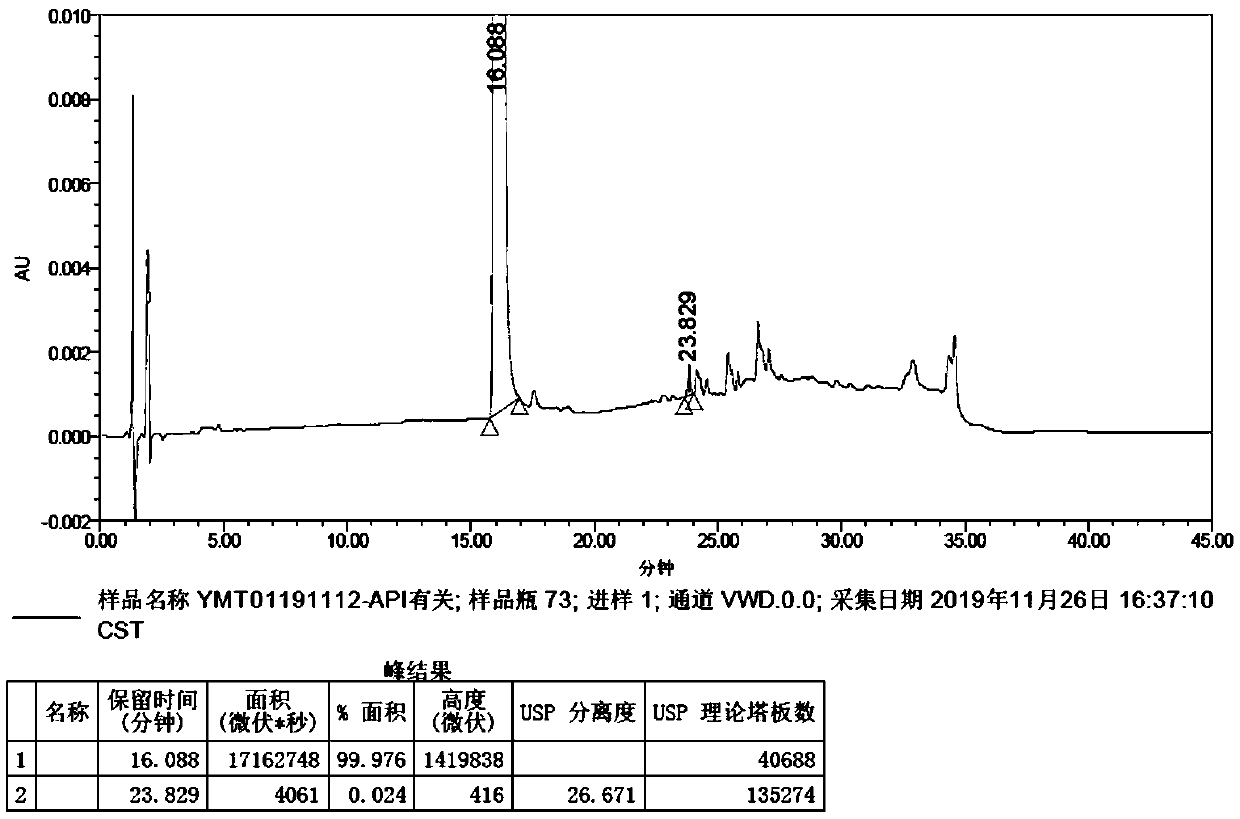

Image

Examples

Embodiment 1

[0032] Embodiment 1: medetomidine is synthesized

[0033] Under nitrogen protection, titanium tetrachloride (5.62g, 29.65mmol) was added to dichloromethane (55ml), cooled to 25°C, starting material-2 (7.49g, 53.37mmol) was diluted with dichloromethane (10ml) , added dropwise to the reaction solution, temperature controlled not to exceed 35°C, and stirred for 30 minutes after addition; starting material-1 (5.00g, 29.65mmol) was diluted with dichloromethane (10)ml, added to the reaction solution, added After heating up to 35°C for 2 hours, take the reaction liquid for monitoring, add water (50ml), stir for 15 minutes, discard the upper organic layer, extract the remaining solution with water (50ml*2), combine the aqueous phases, and use methyl tert-butyl Ether (50ml) was extracted by reaction, and the aqueous phase was extracted with 30% NaOH solution and dichloromethane (50ml*2) to adjust alkali (pH ≥ 10), washed with water (50ml), dried over anhydrous sodium sulfate, and final...

Embodiment 2

[0034] Embodiment 2: medetomidine is synthesized

[0035] Under nitrogen protection, titanium tetrachloride (6.18g, 32.62mmol) was added in dichloromethane (55ml), cooled to 0-10°C, starting material-2 (7.49g, 53.37mmol) was mixed with dichloromethane (10ml ) was diluted, quickly added to the reaction solution, and stirred for 30 minutes after the addition; the starting material-1 (5.00g, 29.65mmol) was diluted with dichloromethane (10)ml, added to the reaction solution, and the temperature was raised to 35°C after the addition React for 2 hours, take the reaction solution for monitoring, add water (50ml), stir for 30 minutes, discard the upper organic layer, extract the remaining solution with water (50ml*2), combine the aqueous phases, and react with methyl tert-butyl ether (50ml) extraction, the aqueous phase was extracted with 30% NaOH solution and dichloromethane (50ml*2) to adjust alkali (pH ≥ 10), washed with water (50ml), dried over anhydrous sodium sulfate, and finall...

Embodiment 3

[0036] Embodiment 3: the synthesis of dexmedetomidine tartrate

[0037] Add medetomidine (5.00g, 24.96mmol) into ethanol (80ml), add 0.4eq L-tartrate, heat to 75°C and stir to dissolve, cool to 15°C for crystallization for 1 hour, filter to obtain tartrate Crude. The crude tartrate was added to 90% ethanol / water (30ml), heated to 70°C to dissolve, cooled to 5°C to crystallize for 1 hour, filtered, and dried to obtain a white solid. The white solid was obtained by repeating the above steps and then refined once to obtain the finished product of tartrate. Finally, it was filtered, washed with an appropriate amount of ethanol, and drained. The rate is 36.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com