Water purification type unfired ceramsite and preparation method

A technology of ceramsite and water purification, applied in chemical instruments and methods, water/sewage treatment, adsorption water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

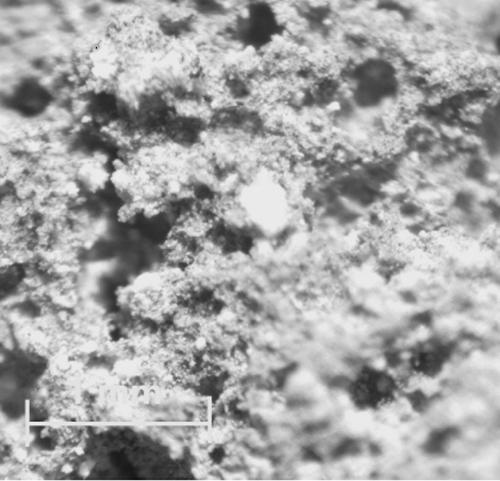

Image

Examples

Embodiment 1

[0029] A preparation method of water-purifying type unfired ceramsite, comprising the following steps:

[0030] S1. Take 30 parts by weight of raw materials fly ash, 10 parts of starch, 10 parts of calcium oxide, 1 part of desulfurized gypsum, and 5 parts of sodium perborate and mix them evenly to obtain a mixture;

[0031] S2. Put the mixed material in S1 in a pan granulator, spray 30 parts by weight of water into the granulator at a flow rate of 1 part / minute to obtain ceramsite green balls; the water temperature is lower than 15 ℃; the rotating speed of the disc granulator is 20 rpm, and the inclination angle is 30 degrees;

[0032] S3, sieving the ceramsite green balls described in S2 to obtain ceramsite green balls with a particle size of 8-20 mm;

[0033] S4. Put the raw ceramsite balls described in S3 into a steam curing device for curing. The air humidity in the curing device should be greater than 70%. The curing temperature program is: curing at 40 degrees Celsius f...

Embodiment 2

[0043] A preparation method of water-purifying type unfired ceramsite, comprising the following steps:

[0044] S1, take by weight 75 parts of raw material fly ash, 35 parts of starch, 40 parts of calcium oxide, 2 parts of desulfurized gypsum, 20 parts of sodium perborate and mix evenly to obtain a mixture;

[0045] S2. Put the mixed material in S1 in a pan granulator, and spray 50 parts by weight of water into the granulator at a flow rate of 5 parts / minute to obtain ceramsite green balls; the water temperature is lower than 15 °C; the rotating speed of the disc granulator is 50 rpm, and the inclination angle is 50 degrees;

[0046] S3, sieving the ceramsite green balls described in S2 to obtain ceramsite green balls with a particle size of 8-20 mm;

[0047] S4. Put the raw ceramsite balls described in S3 in a steam curing device for curing. The air humidity in the curing device should be greater than 70%. The curing temperature program is: curing at 70 degrees Celsius for 0...

Embodiment 3

[0057] A preparation method of water-purifying type unfired ceramsite, comprising the following steps:

[0058] S1, take by weight 50 parts of raw material fly ash, 20 parts of starch, 20 parts of calcium oxide, 1 part of desulfurized gypsum, 18 parts of sodium perborate and mix evenly to obtain a mixture;

[0059] S2. Put the mixed material in S1 in a pan granulator, and spray 40 parts by weight of water into the granulator at a flow rate of 3 parts / minute to obtain ceramsite green balls; the water temperature is lower than 15 ℃; the rotating speed of the disc granulator is 30 rpm, and the inclination angle is 40 degrees;

[0060] S3, sieving the ceramsite green balls described in S2 to obtain ceramsite green balls with a particle size of 8-20 mm;

[0061] S4. Put the raw ceramsite balls described in S3 into a steam curing device for curing. The air humidity in the curing device should be greater than 70%. The curing temperature program is: curing at 50 degrees Celsius for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com