Warehouse logistics goods loading and unloading automatic carrying and conveying intelligent equipment

A technology of warehousing logistics and intelligent equipment, applied in the field of warehousing, logistics and transportation, can solve problems such as difficulty in pushing, inability to adjust the angle of cargo transportation, and inability to apply to goods of different sizes, so as to reduce labor intensity, improve logistics operation efficiency and service quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in a variety of different ways defined and covered by the claims.

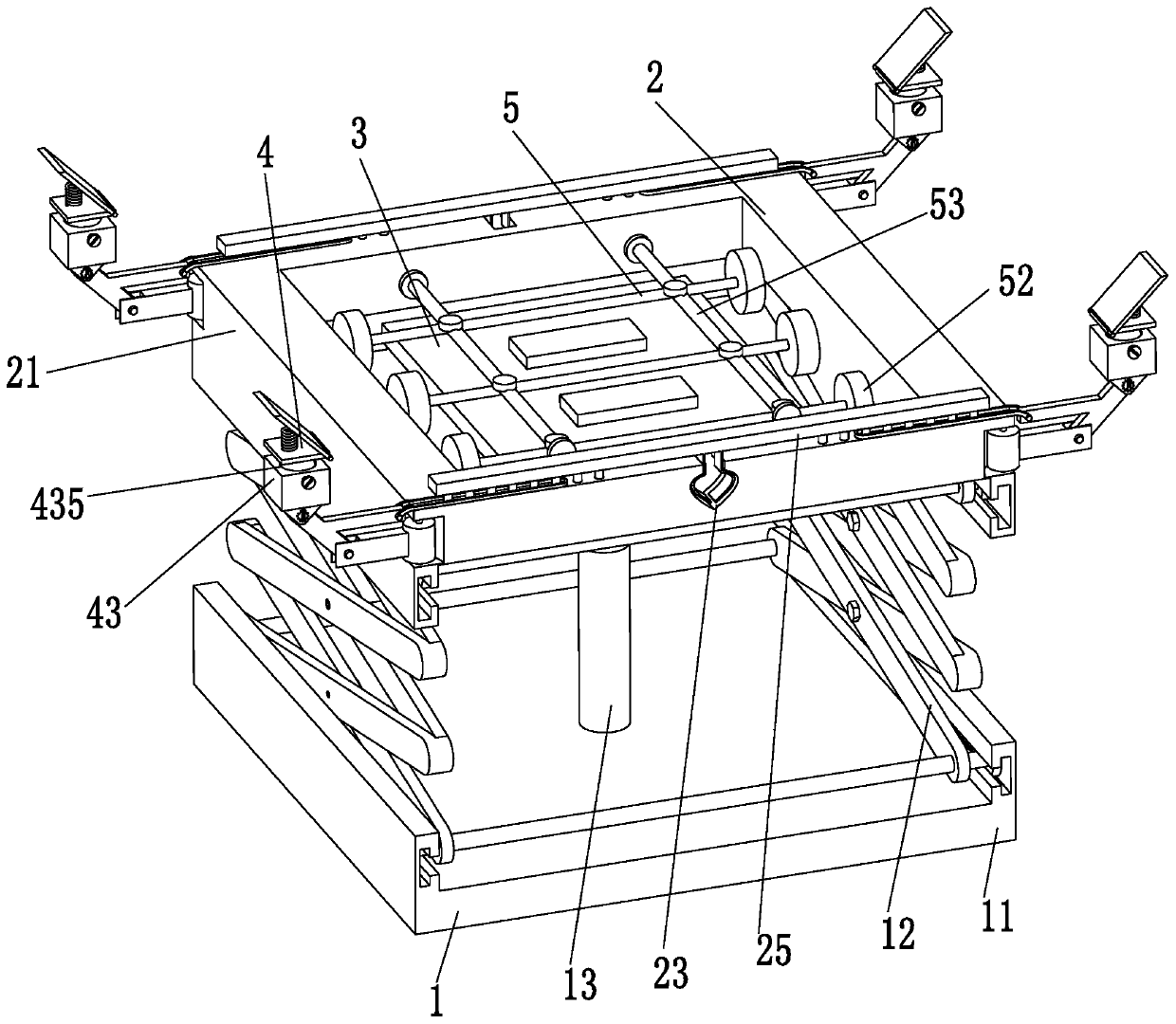

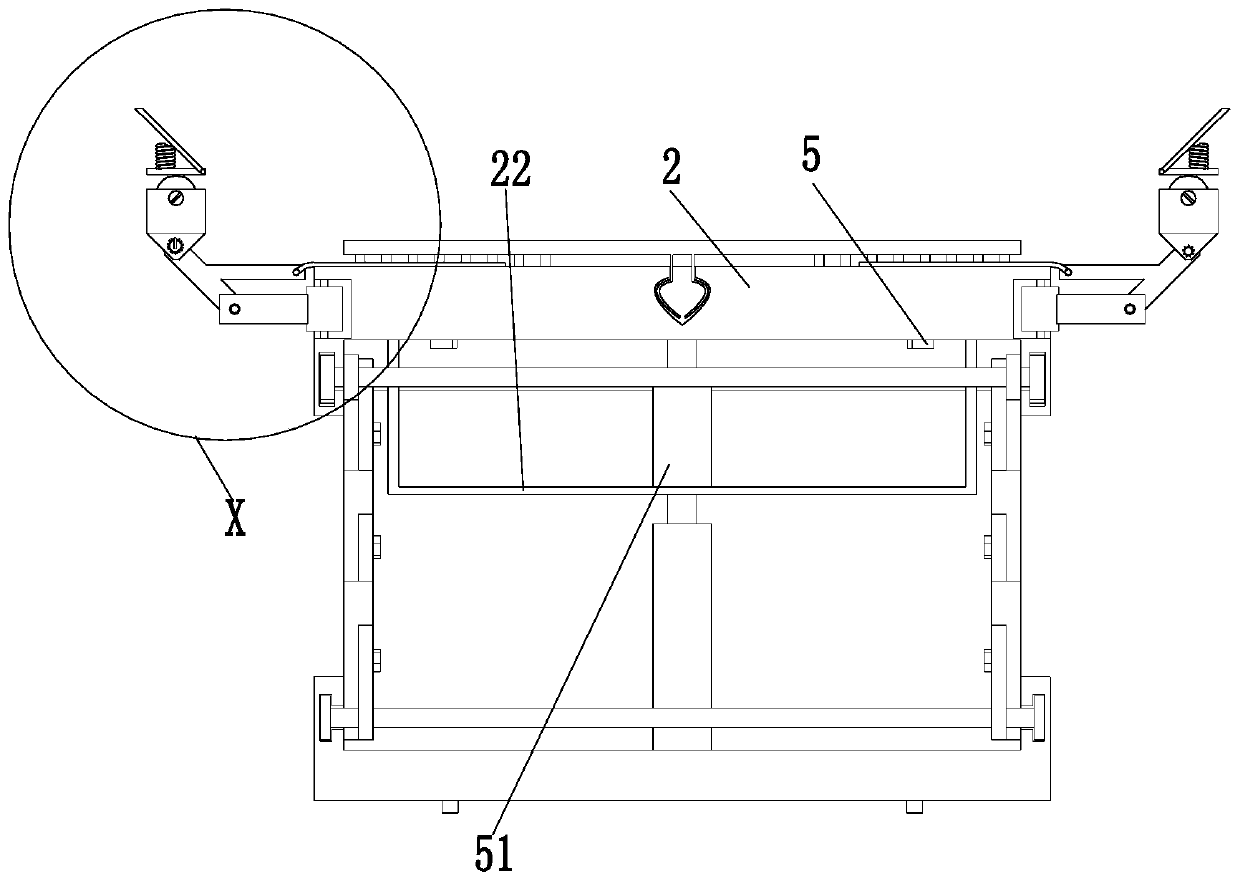

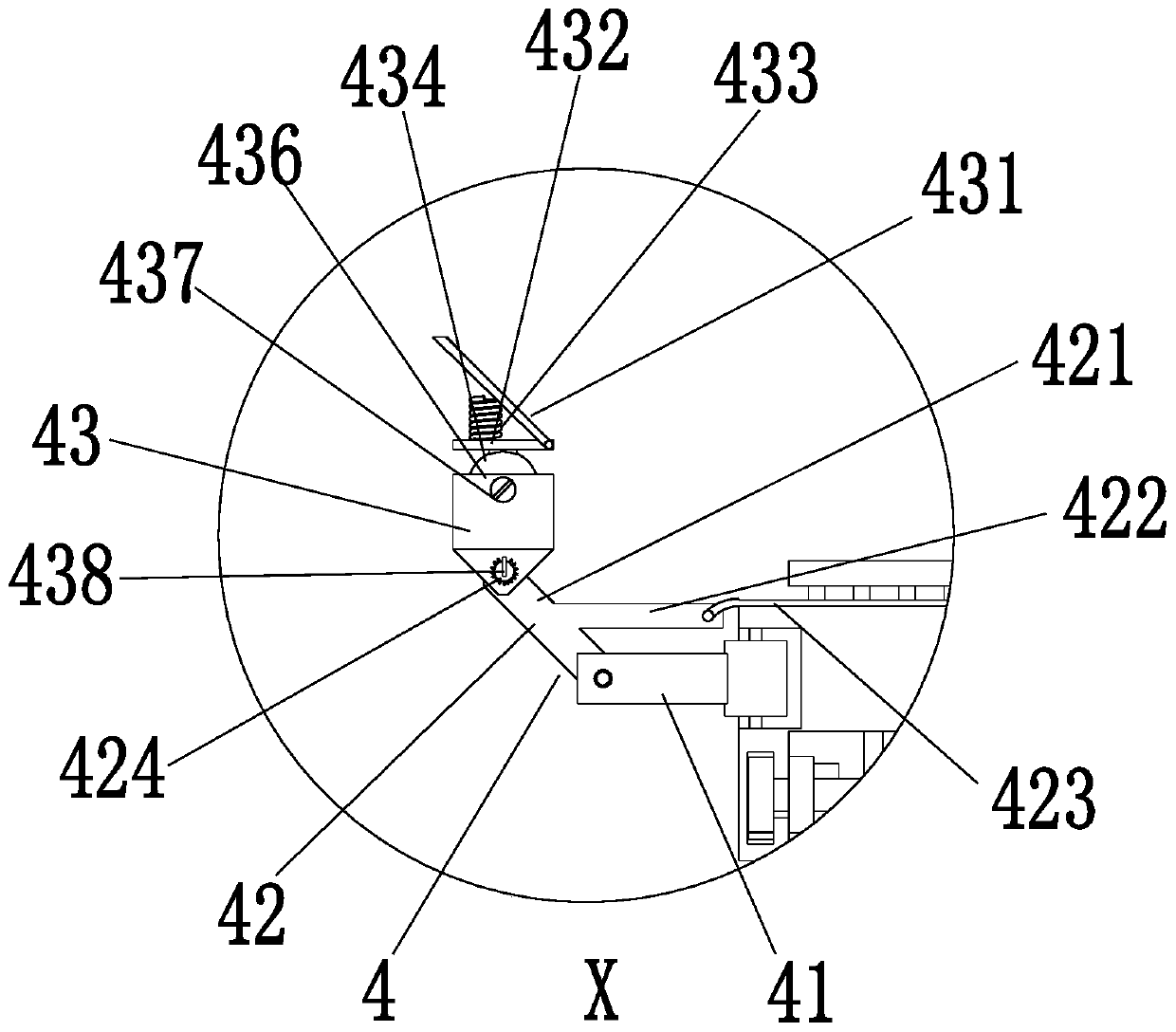

[0030] Such as Figure 1 to Figure 6 As shown, an intelligent equipment for automated handling and conveying of goods in warehousing and logistics includes a fixed base 1, a mounting base 2, a working plate 3, a supporting device 4, and a discharging device 5. A mounting base 2 is installed on the upper end of the fixed base 1 , The inside of the installation base 2 is provided with a working plate 3, the installation base 2 is evenly installed with a supporting device 4, and the upper end of the working plate 3 is installed with a discharging device 5.

[0031] The fixed base 1 includes a bottom fixing plate 11, a lifting and shrinking frame 12, and a No. 1 cylinder 13. The left and right ends of the bottom fixing plate 11 are symmetrically inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com