Mechanical automatic machine tool console

A technology for consoles and machine tools, which is applied to metal processing mechanical parts, large fixed members, metal processing equipment, etc., can solve the problems of low work efficiency, easy dust contamination of the console, and easy damage to the components of the console, so as to achieve stable fixation. effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

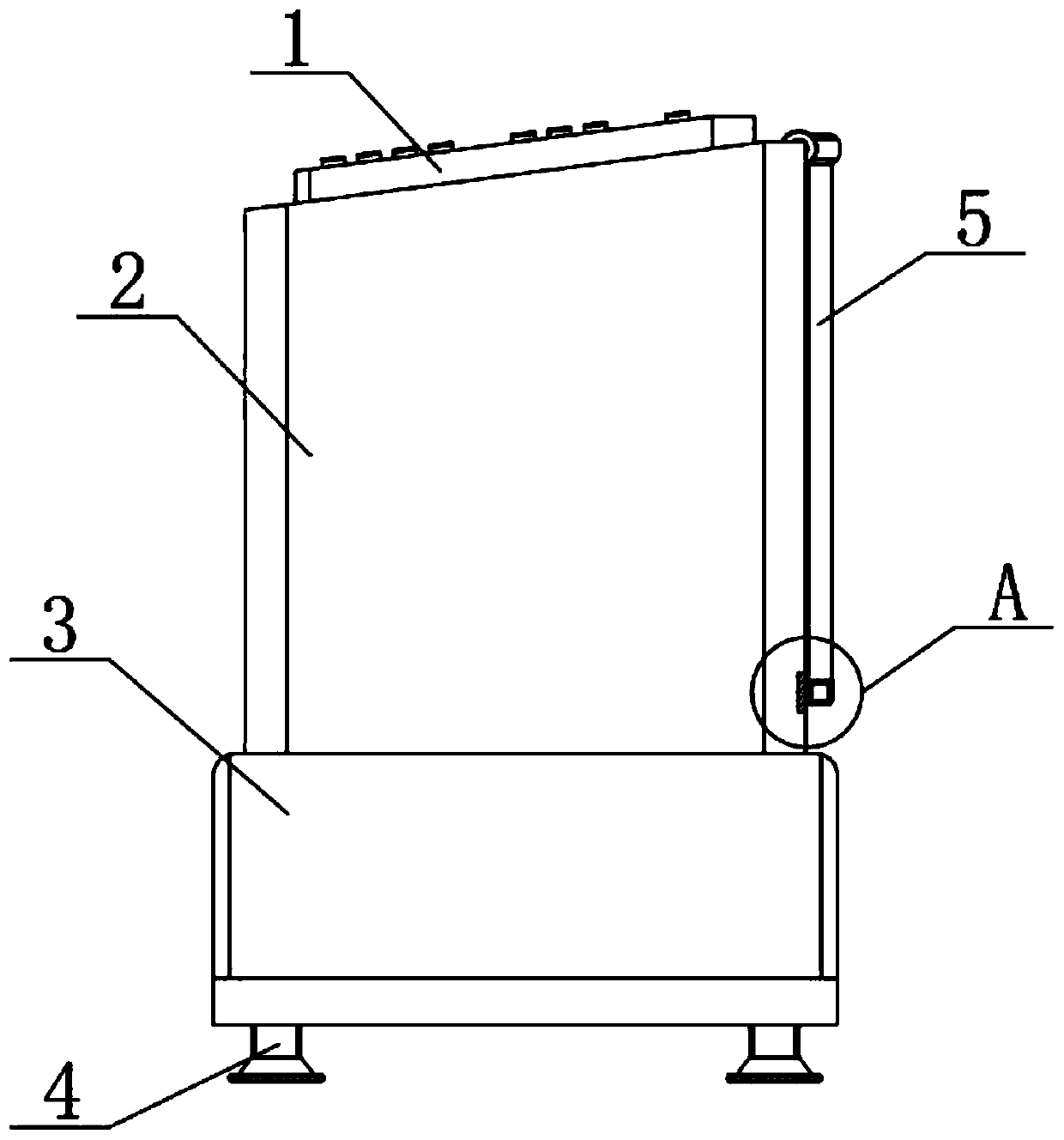

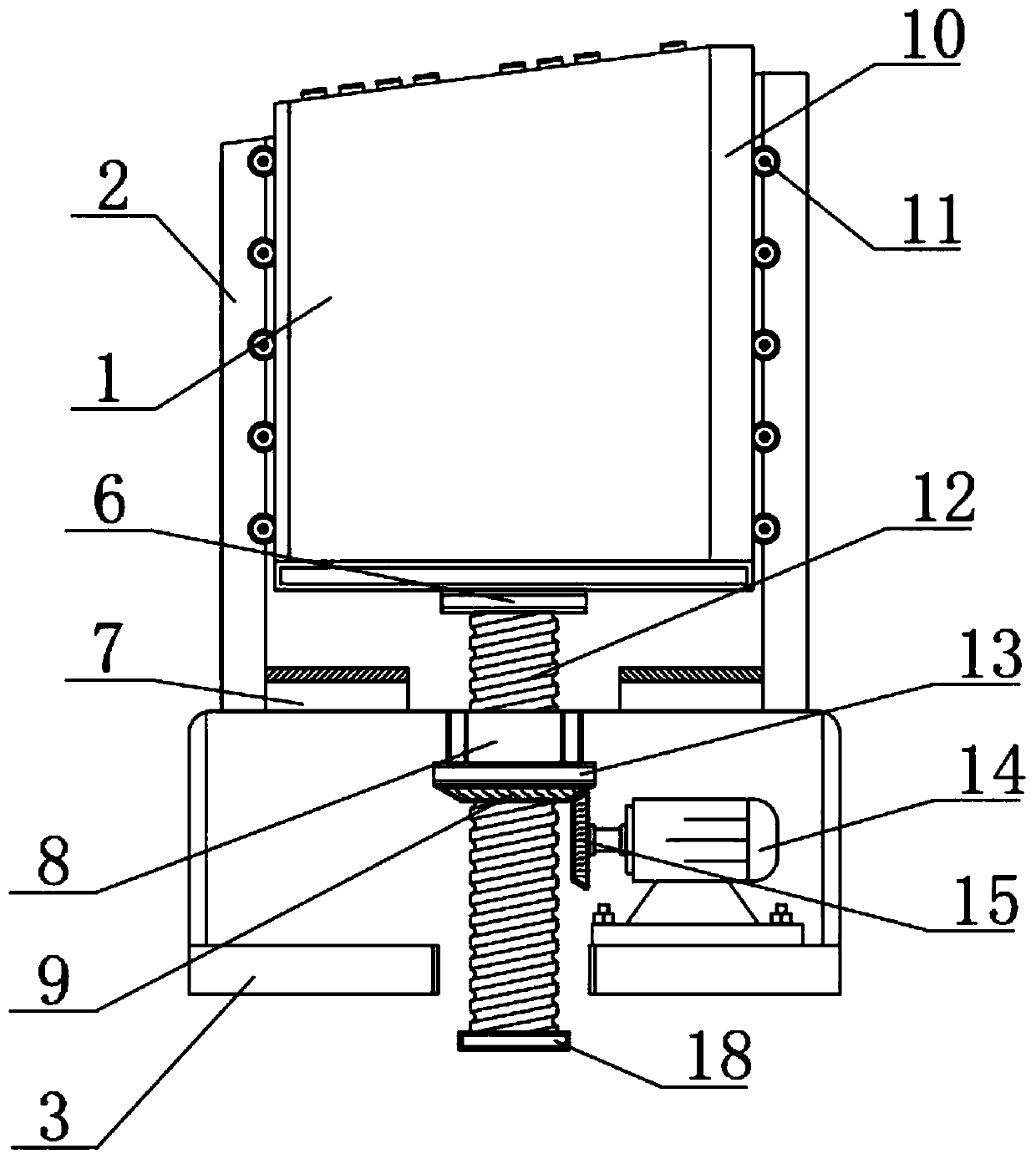

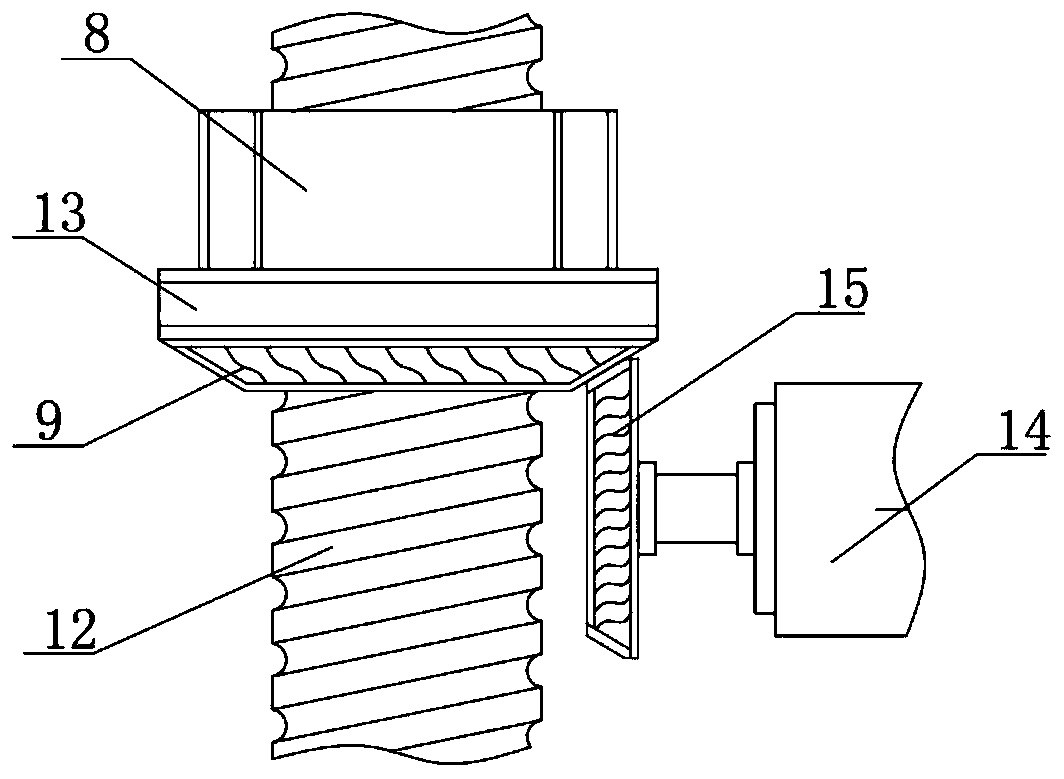

[0020] see Figure 1-4 , the structure of a mechanical automation machine tool console of the present invention, please refer to Figure 1-4 , the present invention provides the following technical solutions: a mechanical automation machine tool console, including a lifting frame 2 and a base 3, and an operating table 1 slidingly connected to the inside of the lifting frame 2, the lower surface of the operating table 1 is rotatably connected with a bearing 6, and the operation The table 1 is connected with the lifting screw 12 through the bearing 6. The inside of the base 3 is fixed with a motor 14 by bolts. The output end of the motor 14 is connected with the second bevel gear 15 in rotation. The inside of the base 3 is integrally formed with a screw channel tube 8 The lower surface of the screw-in channel pipe 8 is connected with a rotating ring 13, and the lower surface of the rotating ring 13 is integrally formed with a No. 1 bevel gear 9, and the outer surfaces of the No....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com