Spray head, spray washing device and dish washing machine

A technology of spray washing device and spray head, which is applied in the direction of washing machine/washing machine for tableware, parts of washing machine/rinsing washing machine for tableware, household cleaning device, etc. Complexity and other issues, to achieve the effect of easy cleaning and enhanced viewing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

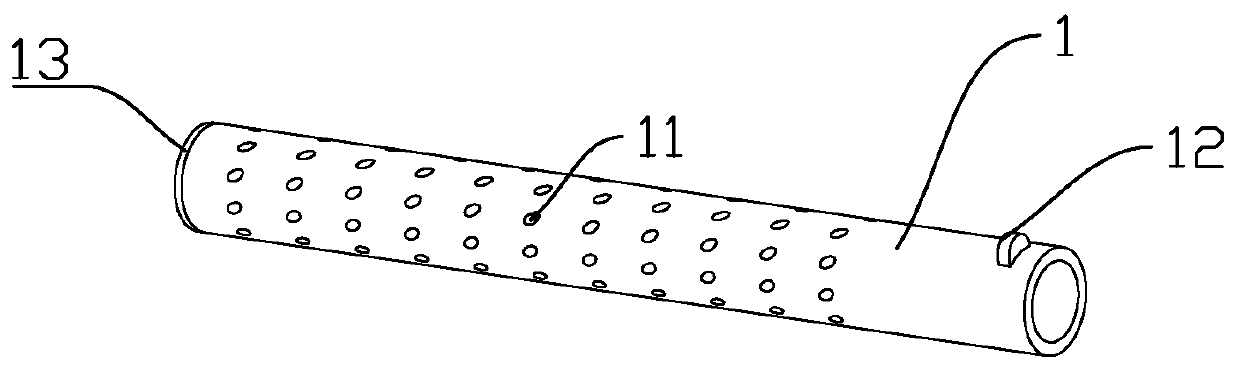

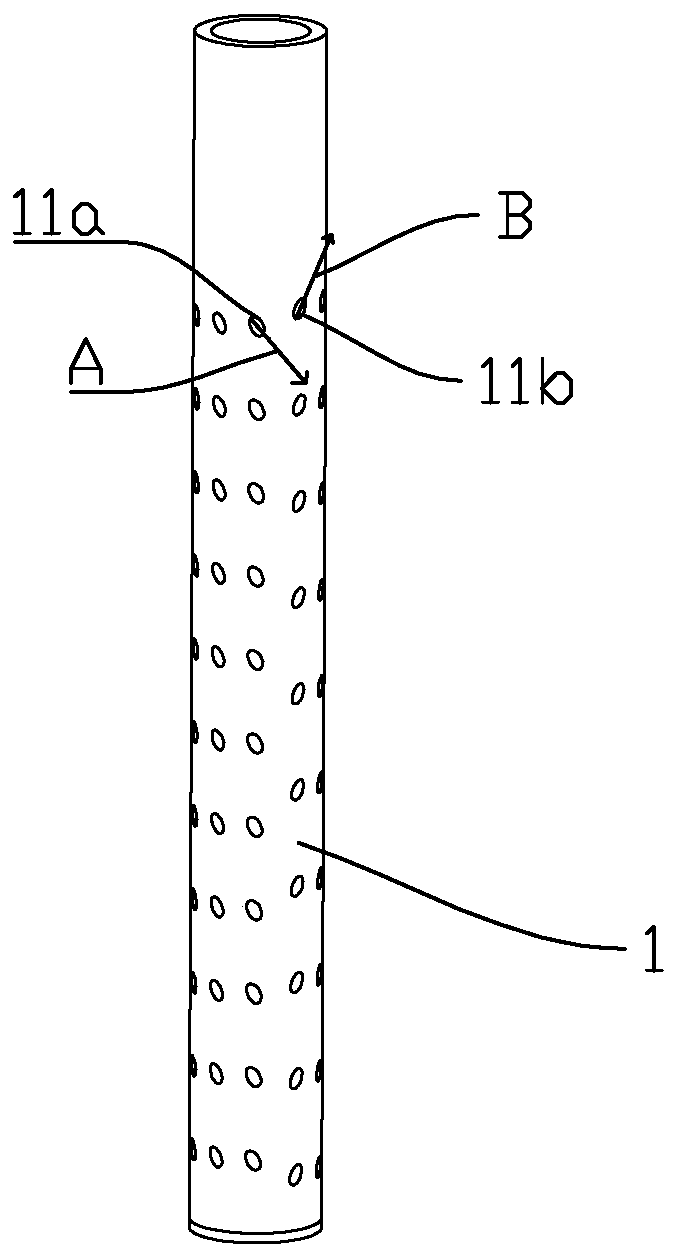

[0036] Refer to attached Figure 1-Figure 2 : A sprinkler head, comprising a tubular water spray pipe 1, one end of the water spray pipe 1 is open (water inlet), the other end is connected with a cover plate 13, the side wall of the water spray pipe 1 is provided with a number of water spray, and The water spray hole 11 that drives the water spray pipe 1 to rotate in one direction around the central axis, the water spray hole 11 includes a water spray hole 11a and a water spray hole 11b, and the water discharge direction of the water spray hole 11a is biased towards one end of the water spray pipe 1 , the water outlet direction of the water spray hole 11b is biased towards the other end of the water spray pipe 1; the water spray holes 11a are arranged in several columns at equal intervals along the circumference of the water spray pipe 1, and there are several water spray holes 11a in each column, and along the The water spray pipes 1 are arranged at equal intervals in the axi...

Embodiment 2

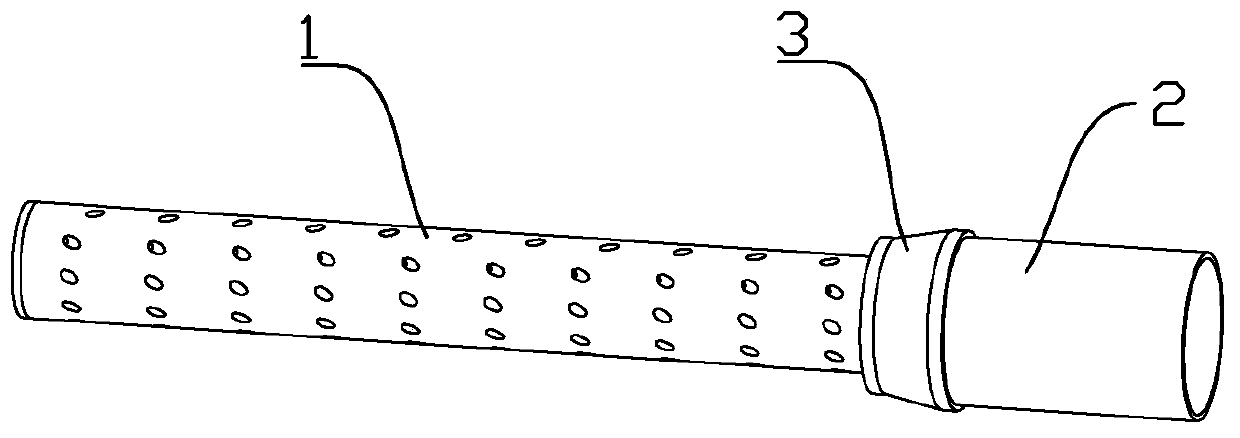

[0039] Refer to attached Figure 3-Figure 5 , a spray washing device, comprising the water spray pipe 1 in embodiment 1, the water spray holes 11a of the same row and the cross section angle of the water spray pipe 1 are the same, the water spray holes 11b of the same row and the water spray pipe 1 cross section The included angles are the same, so that the sprayed water columns of the same column can be prevented from intersecting each other, and the impact force can be prevented from canceling each other. The part of the water spray pipe 1 close to the opening is covered with a connecting pipe 2, and a connecting sleeve 3 connecting the outer walls of the two is provided between the water spray pipe 1 and the connecting pipe 2, and a friction mechanism for assisting the twisting of the water spray pipe 1 And a concentric mechanism that keeps the two in the direction of the concentric axis; the connecting sleeve 3 is rotatably connected with the water spray pipe 1, and the co...

Embodiment 3

[0047] A dishwasher, comprising the spray washing device described in Embodiment 2, the spray washing device is arranged on the inner cavity of the dishwasher, and the connecting pipe is connected to a water source for washing dishes. The arrangement direction of the dishes is parallel to the axial row of the water spray pipes, and the dishes are not easy to be placed obliquely. The second collision head can be provided with a plurality of, but must have a second collision head and the dish to be on the same side of the water spray pipe. The angle between the water spray direction of each water spray hole a and the cross section of the water spray pipe is 30 degrees, and the angle between the water spray direction of each water spray hole b and the cross section of the water spray pipe is 30 degrees. Since the front side of the dish (the side where the food is placed) is generally dirty, the back side is generally not dirtier than the front side, so the front side of the dish ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com