Making method of quantitatively marinating sauced pork elbows

A technology for quantitative stewing and production methods, which is applied in climate change adaptation, food science and other directions, can solve the problems of lack of seasoning quantity and the relationship between meat quality and yield, unstable flavor and product quality, lack of quantitative stewing method of pork knuckle, etc. To achieve rich nutritional value, reduce equipment investment costs and energy loss, realize the effects of industrialized regulation and standardized mechanized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Raw meat pretreatment:

[0026] Select pork knuckles with foreign matter such as surface fat and fascia removed by weight, wash and drain for later use;

[0027] (2) Cook the seasoning liquid:

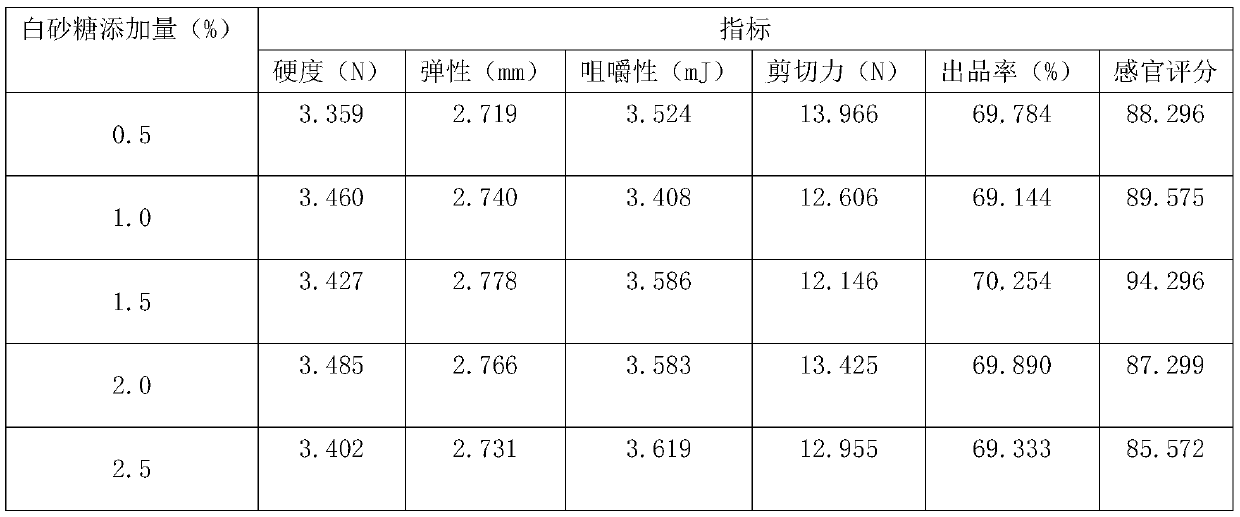

[0028] According to the weight percentage of pork knuckle, take 30% of water, 2.5% of star anise, 1.2% of pepper, 0.5% of cinnamon, 1.2% of pepper, 1.0% of ginger, 0.6% of tangerine peel, 0.5% of licorice, 0.3% of grass fruit, 0.3% of clove, and white pepper 0.2% flour, 2.0% cooking wine, 0.5% pork essence, 0.2% compound phosphate, 2.0% table salt, 1.5% white sugar, 2.0% soy sauce, 1.0% monosodium glutamate, cook for 1 hour, and then fully filter the water with a sieve , filter out the solid matter in the feed water to obtain the seasoning liquid, and cool it for subsequent use;

[0029] (3) Seasoning liquid injection:

[0030] A saline injection machine model ZYZ-80 is used, the injection pressure is 20-40kpa, 8 injection needles, the number of injections is 50 times / min...

Embodiment 2

[0042] (1) Raw meat pretreatment:

[0043] Select pork knuckles with foreign matter such as surface fat and fascia removed by weight, wash and drain for later use;

[0044] (2) Cook the seasoning liquid:

[0045] According to the weight percentage of pork knuckle, take 30% of water, 2.5% of star anise, 1.2% of pepper, 0.5% of cinnamon, 1.2% of pepper, 1.0% of ginger, 0.6% of tangerine peel, 0.5% of licorice, 0.3% of grass fruit, 0.3% of clove, and white pepper 0.2% rice flour, 2.0% cooking wine, 0.5% pork essence, 0.2% compound phosphate, 2.0% table salt, 1.5% white sugar, 2.0% soy sauce, 1.0% monosodium glutamate, cook for 0.5h, and then use a sieve to fully drain the water Filtrate to remove the solid matter in the feed water to obtain the seasoning liquid, which is cooled for subsequent use;

[0046] (3) Seasoning liquid injection:

[0047] A saline injection machine model ZYZ-80 is used, the injection pressure is 20-40kpa, 8 injection needles, the number of injections i...

Embodiment 3

[0059] (1) Raw meat pretreatment:

[0060] Select pork knuckles with foreign matter such as surface fat and fascia removed by weight, wash and drain for later use;

[0061] (2) Cook the seasoning liquid:

[0062] According to the weight percentage of pork knuckle, take 30% of water, 2.5% of star anise, 1.2% of pepper, 0.5% of cinnamon, 1.2% of pepper, 1.0% of ginger, 0.6% of tangerine peel, 0.5% of licorice, 0.3% of grass fruit, 0.3% of clove, and white pepper 0.2% rice flour, 2.0% cooking wine, 0.5% pork essence, 0.2% compound phosphate, 2.5% table salt, 2.0% white sugar, 2.0% soy sauce, 1.0% monosodium glutamate, cook for 0.5h, and then use a sieve to fully drain the water Filtrate to remove the solid matter in the feed water to obtain the seasoning liquid, which is cooled for subsequent use;

[0063] (3) Seasoning liquid injection:

[0064] A saline injection machine model ZYZ-80 is used, the injection pressure is 20-40kpa, 8 injection needles, the number of injections i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com