A new energy charging module

A charging module and new energy technology, applied in the direction of electrical components, power electronics modification, synthetic resin layered products, etc., can solve problems such as the impact of ambient temperature charging module life, equipment, loss of functionality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

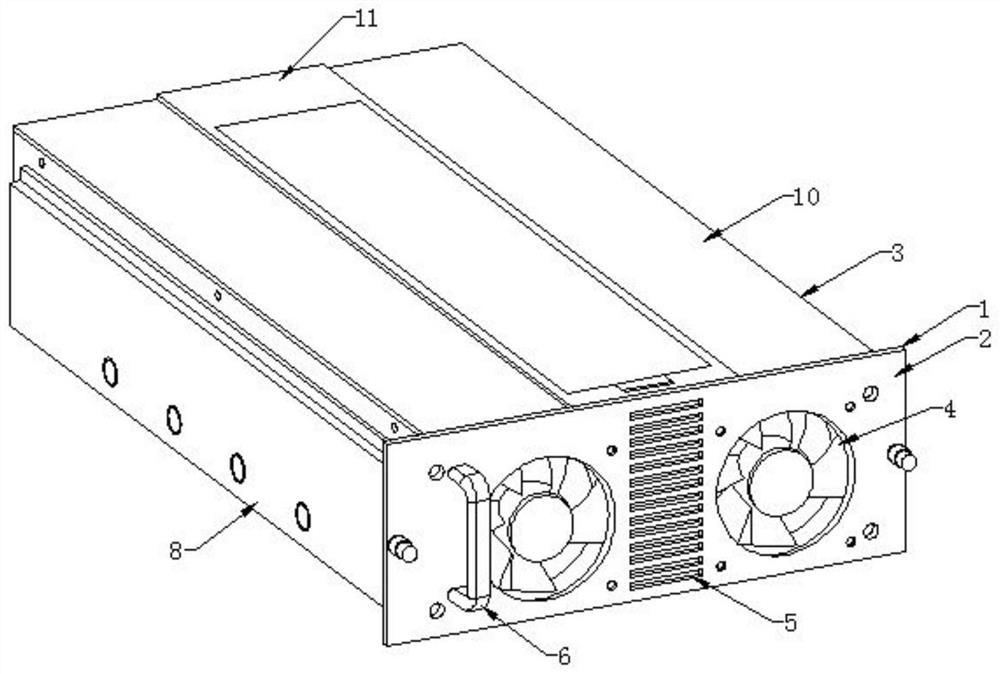

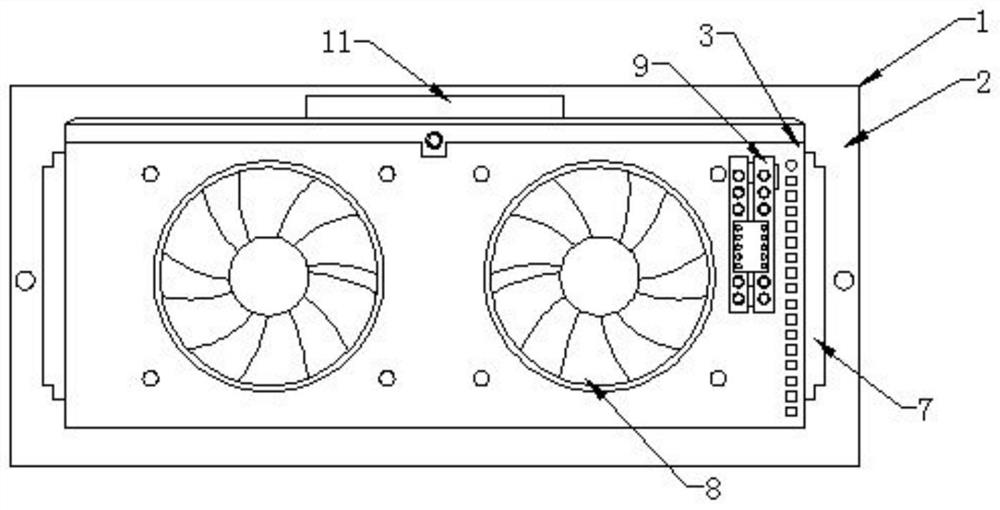

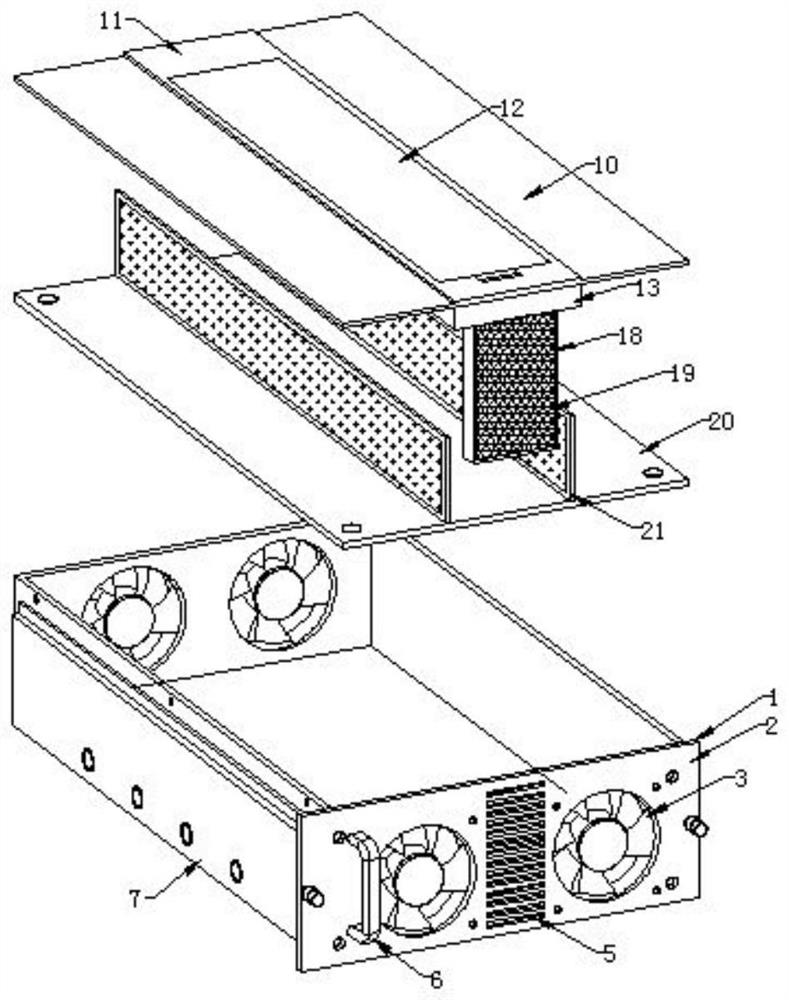

[0025] Such as Figure 1-5 As shown, the present invention provides a new energy charging module, including a charging module main body 1, a front bezel 2 is installed at one end of the charging module main body 1, a box body 3 is installed at one end of the front bezel 2, and a front bezel Front fans 4 are installed on both sides of the surface of the front baffle 2, a cooling vent 5 is installed in the middle of the front baffle 2, a handle 6 is installed on one side of the front fan 4, and side sliding blocks 7 are installed on both sides of the box body 3 A rear fan 8 is installed on both sides of one end surface of the box body 3, a socket 9 is installed on one side of the rear fan 8, a top cover 10 is arranged on the top of the box body 3, and a top sliding block is arranged in the middle of the surface of the top cover 10. 11. A sealing plate 12 is installed at the top middle of the top sliding block 11, an air duct groove 13 is arranged inside the top cover 10, a water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com