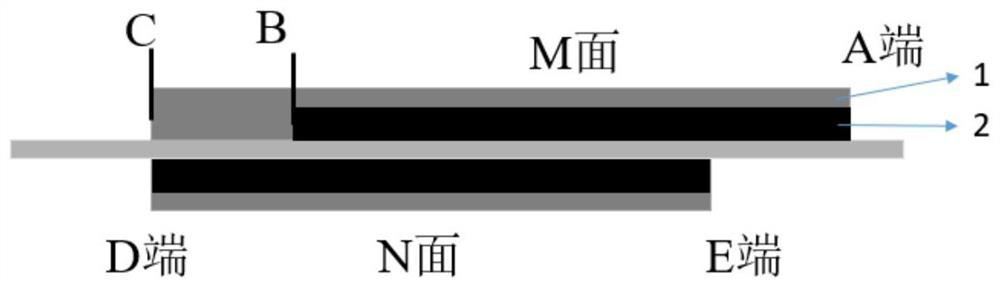

A positive electrode sheet, preparation method and lithium ion battery comprising the same

A positive electrode sheet and a positive electrode current collector technology are applied in the field of a positive electrode sheet, a preparation method and a lithium ion battery including the same, to achieve the effects of improving cycle life, increasing energy density, and increasing compaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0084] The preparation method of above-mentioned negative plate, described method comprises the steps:

[0085] 1) respectively preparing and forming the slurry forming the negative electrode active material layer;

[0086] 2) Using a coating machine, coating the slurry forming the negative electrode active material layer on both surfaces of the negative electrode current collector to prepare the negative electrode sheet.

[0087] Wherein, in step 1), the solid content of the slurry forming the negative electrode active material layer is 40wt%-45wt%.

[0088] The present invention will be further described in detail below in conjunction with specific embodiments. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of pro...

Embodiment 1

[0093] The first step: prepare the slurry for forming the first positive electrode active material layer: mix the first positive electrode active material (lithium cobaltate), the first conductive agent (conductive carbon black) and the first binder (PVDF) according to 97.2:1.5 : The mass ratio of 1.3 is added to the stirring tank, NMP is added to be mixed with the slurry forming the first positive electrode active material layer, and the solid content of the positive electrode slurry is 70wt%~75wt%; wherein, the particle diameter of the first positive electrode active material The distribution is: 5μm10 50 90 <45μm;

[0094] The second step: prepare the slurry forming the second positive electrode active material layer: mix the second positive electrode active material (lithium cobaltate), the second conductive agent (conductive carbon black) and the second binder (PVDF) according to 97.2:1.5 : The mass ratio of 1.3 is added to the stirring tank, NMP is added to be mixed with...

Embodiment 2-3 and comparative example 1-2

[0103] The other operating steps are the same as in Example 1, except that the thicknesses of the first positive electrode active material layer and the second positive electrode active material layer in the single-sided coating area and the double-sided coating area are different, as shown in Table 1.

[0104] The structural parameters of the positive electrode sheet of table 1 embodiment 1-3 and comparative example 1-2

[0105]

[0106] In Table 1, the thickness before " / " represents the thickness of the first positive electrode active material layer, and the thickness after " / " represents the thickness of the second positive electrode active material layer; taking 5 μm / 75 μm as an example, the thickness of the second coating layer The thickness of the first positive electrode active material layer was 5 μm, and the thickness of the second positive electrode active material layer in the second coating layer was 75 μm.

[0107] The positive electrode sheets prepared in eac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com