A crystalline-amorphous moo for supercapacitors 3 @ni 3 the s 2 Material preparation method

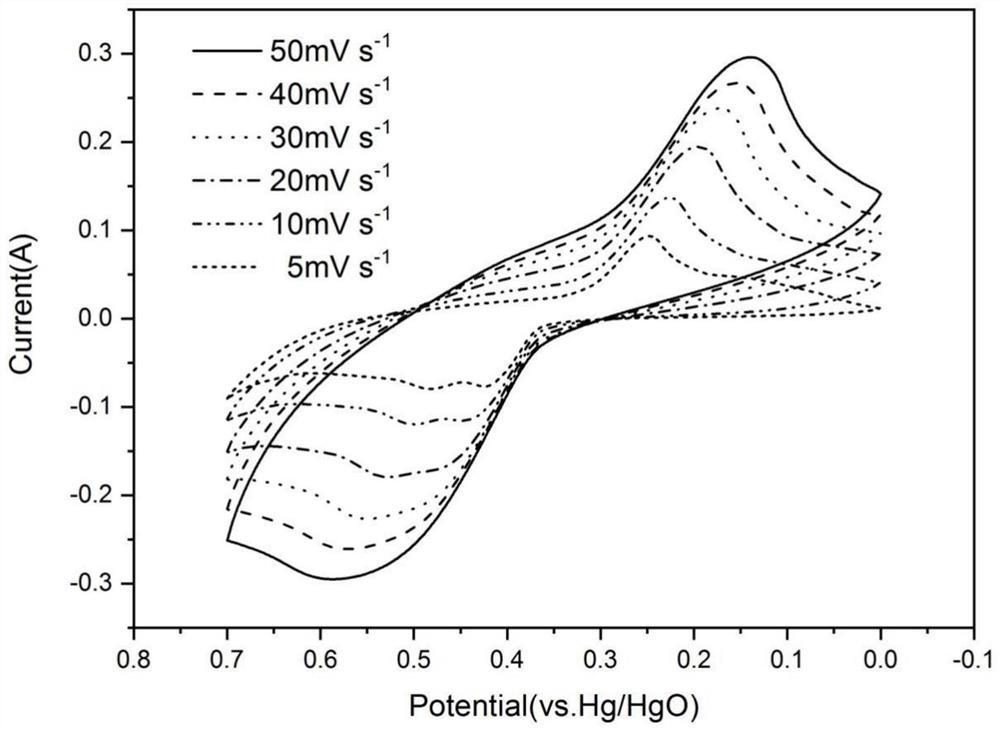

A supercapacitor, amorphous technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of poor cycle performance of materials, and achieve the effect of enhancing capacitance performance, improving cycle stability, and enriching redox reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

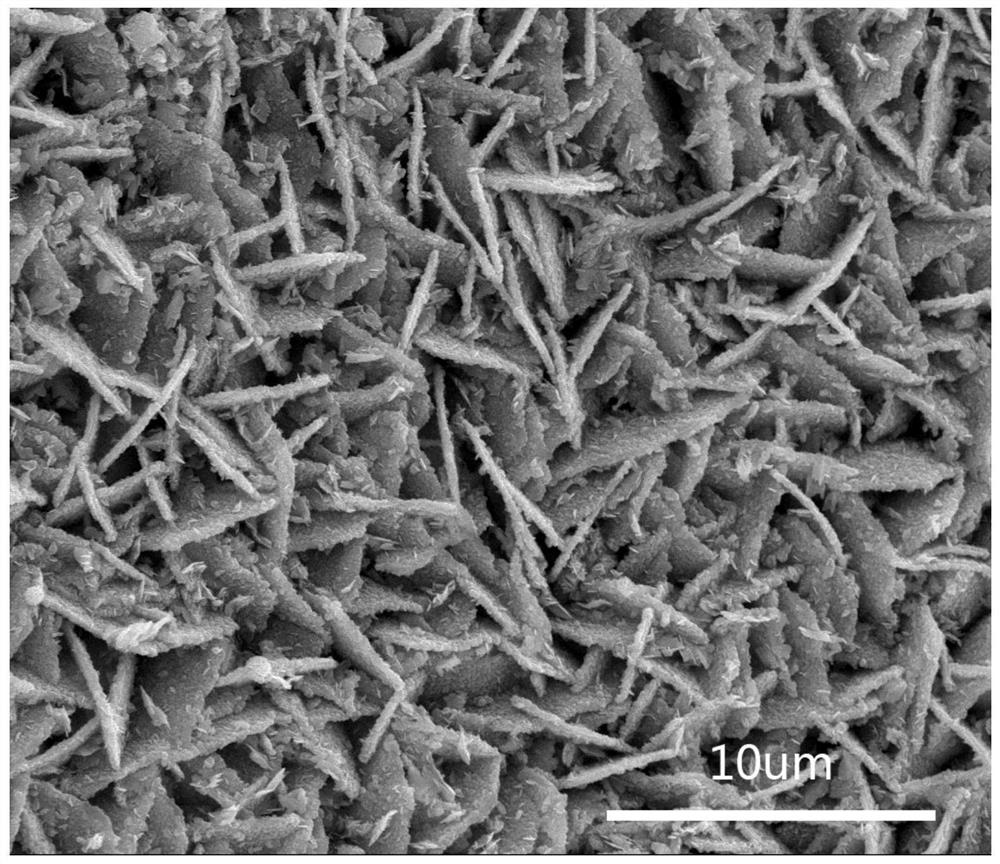

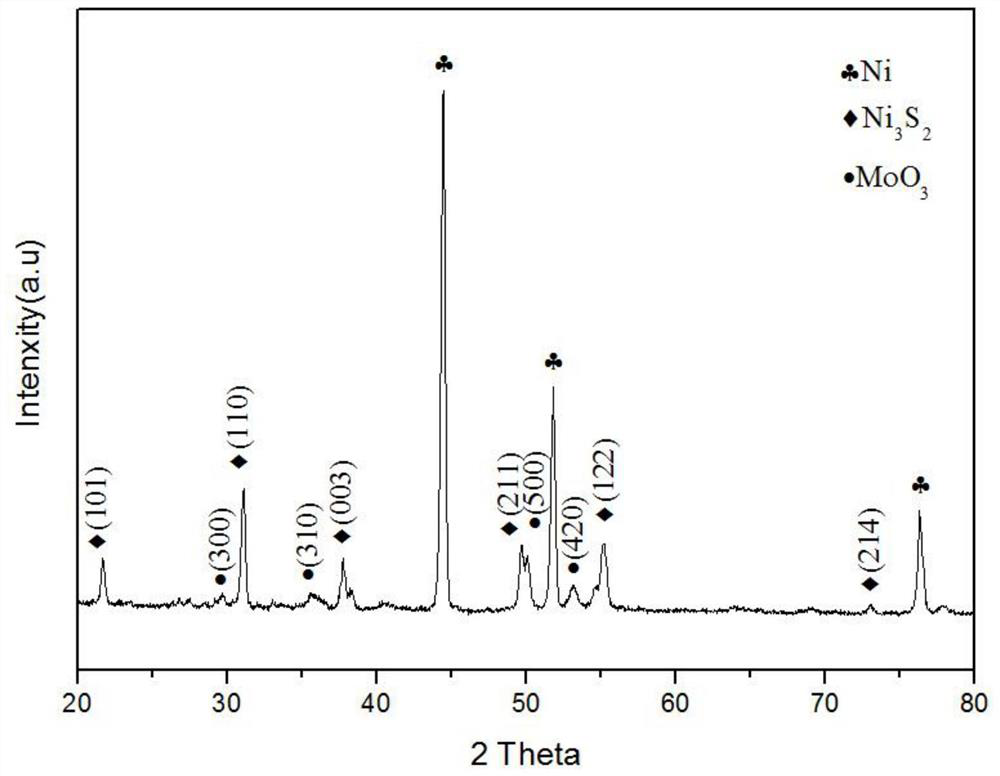

[0024] A kind of supercapacitor electrode material MoO 3 @Ni 3 S 2 The preparation method, the crystalline-amorphous MoO 3 @Ni 3 S 2 The preparation method comprises the following steps:

[0025] Step 1: Pretreatment of foamed nickel: respectively immerse the foamed nickel in 3mol / L dilute hydrochloric acid, absolute ethanol and deionized water for 20 minutes to remove impurities on the surface, and dry 12 pieces in a vacuum drying oven at 40 degrees Celsius Hour;

[0026] Step 2: take by weighing 150mg thioacetamide (CH 3 CSNH 2 ) was dissolved in 100ml deionized water, dispersed by ultrasonic to form a homogeneous solution, added foamed nickel processed in step 1, reacted at 180 degrees Celsius for 24 hours, washed foamed nickel alternately with deionized water and absolute ethanol, and then washed the foamed nickel at 60 degrees Celsius After vacuum drying for 10 hours, a self-supporting Ni foam based on nickel foam was obtained. 3 S 2 @NFMaterial;

[0027] Step ...

example 2

[0029] Step 1: Pretreatment of foamed nickel: respectively immerse the foamed nickel in 3mol / L dilute hydrochloric acid, absolute ethanol and deionized water for 20 minutes to remove impurities on the surface, and dry 12 pieces in a vacuum drying oven at 40 degrees Celsius Hour;

[0030] Step 2: take by weighing 150mg thioacetamide (CH 3 CSNH 2 ) was dissolved in 100ml deionized water, dispersed by ultrasonic to form a homogeneous solution, added foamed nickel processed in step 1, reacted at 180 degrees Celsius for 24 hours, washed foamed nickel alternately with deionized water and absolute ethanol, and then washed the foamed nickel at 60 degrees Celsius After vacuum drying for 10 hours, a self-supporting Ni foam based on nickel foam was obtained. 3 S 2 @NFMaterial;

[0031] Step 3: take by weighing 0.5g ammonium molybdate ((NH 4 ) 6 MO 7 o 24 4H 2 O) dissolved in 30ml deionized water and 4ml ethylene glycol ((CH 2 Oh) 2 ) in the mixed solution, form a homogeneous s...

example 3

[0034] Step 1: Pretreatment of foamed nickel: respectively immerse the foamed nickel in 3mol / L dilute hydrochloric acid, absolute ethanol and deionized water for 20 minutes to remove impurities on the surface, and dry 12 pieces in a vacuum drying oven at 40 degrees Celsius Hour;

[0035] Step 2: take by weighing 150mg thioacetamide (CH 3 CSNH 2 ) was dissolved in 100ml deionized water, dispersed by ultrasonic to form a homogeneous solution, added foamed nickel processed in step 1, reacted at 180 degrees Celsius for 24 hours, washed foamed nickel alternately with deionized water and absolute ethanol, and then washed the foamed nickel at 60 degrees Celsius After vacuum drying for 10 hours, a self-supporting Ni foam based on nickel foam was obtained. 3 S 2 @NFMaterial;

[0036] Step 3: take by weighing 1g ammonium molybdate ((NH 4 ) 6 MO 7 o 24 4H 2 O) dissolved in 30ml deionized water and 4ml ethylene glycol ((CH 2 Oh) 2 ) in the mixed solution, form a homogeneous sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com