Modeling method for automatic leveling system for aerial work platform chassis

A technology for aerial work platform and system modeling, applied in the field of self-leveling system modeling of aerial work platform chassis, to achieve the effect of accurate numerical value, simplified complexity, and accurate action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

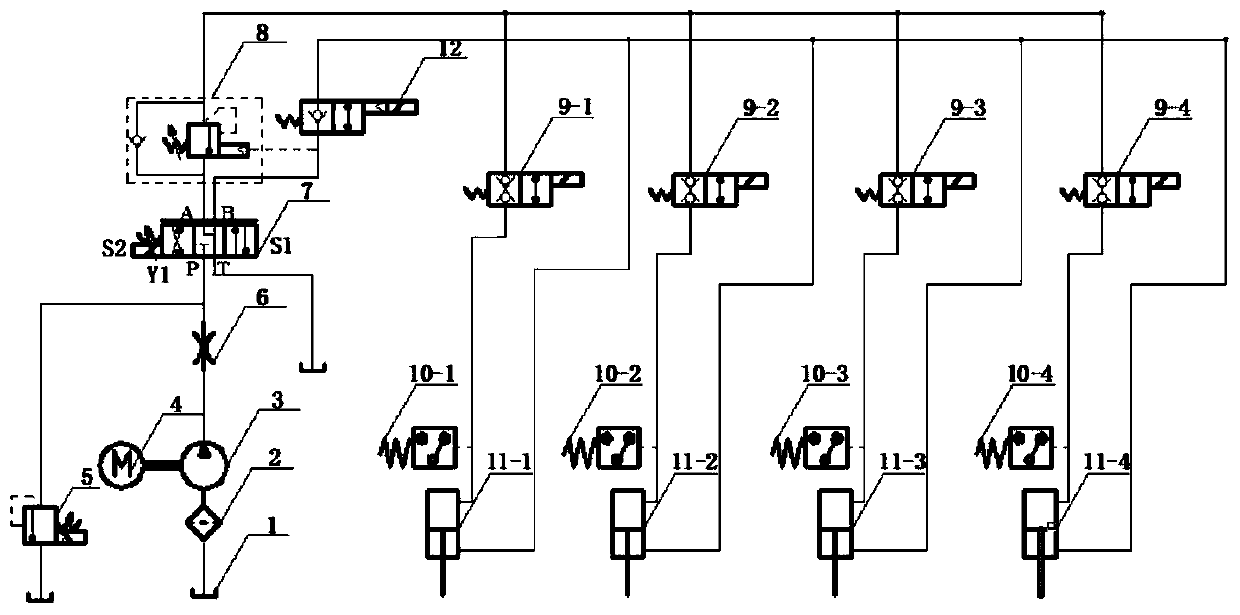

[0077] The invention provides a modeling method for the chassis leveling program of an aerial work platform. Based on a four-point support hydraulic leveling system, the angle error leveling method is used to perform corresponding leveling operations on the chassis, and the aerial work platform Chassis for support.

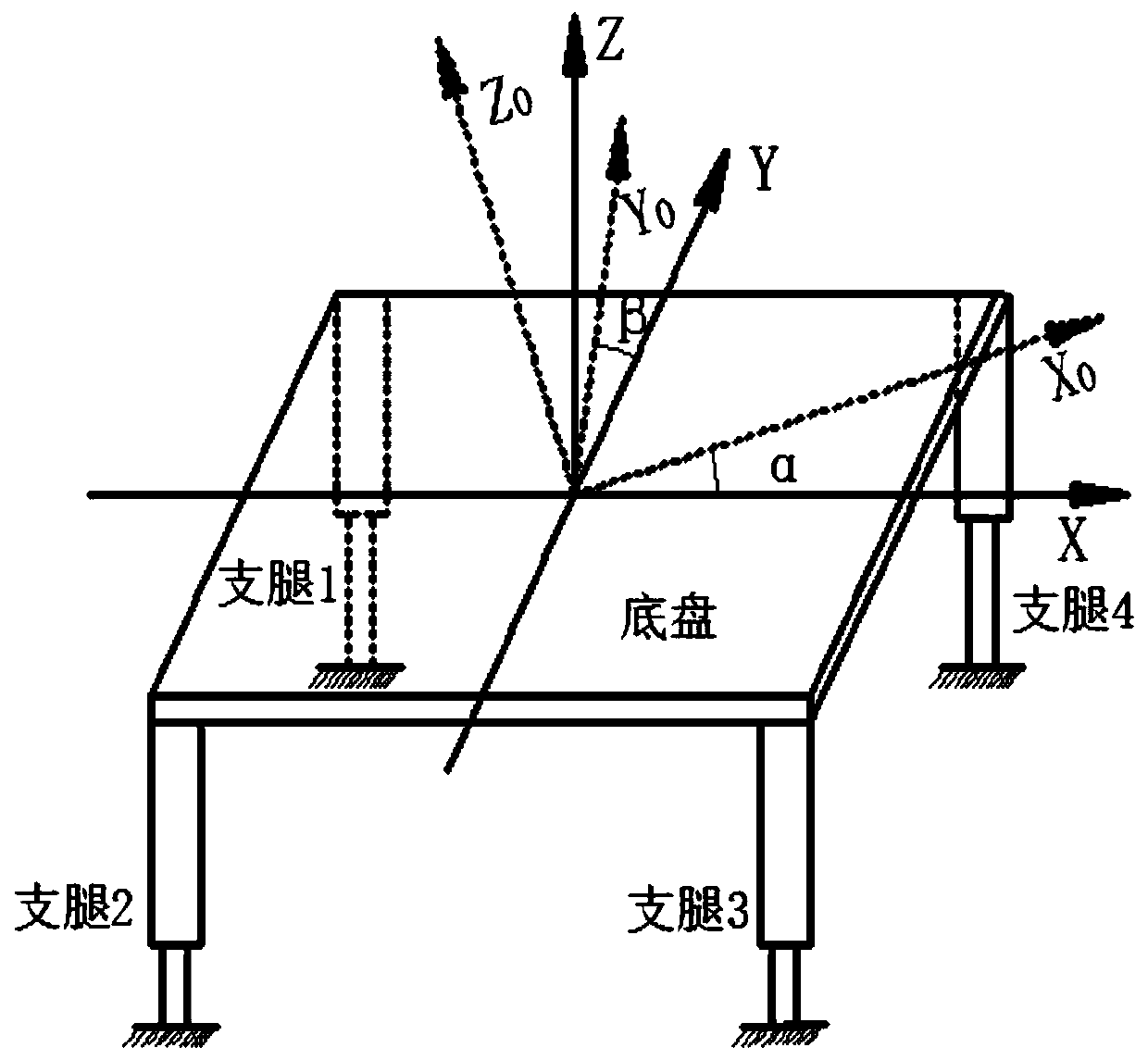

[0078] see figure 1 with figure 2 , the chassis of the aerial work platform is composed of a chassis and four legs supporting the chassis. figure 2 Among them, XYZ is the ideal horizontal coordinate system of the chassis, and X 0 Y 0 Z 0 is the chassis initial state coordinate system, α is the angle between the X axis and the X0 axis, indicating the inclination angle of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com