Detection method of chip module

A detection method and technology for chip modules, which are applied in measurement devices, optical testing of flaws/defects, material analysis by optical means, etc., can solve the problems of inability to detect chips, low efficiency, and inconvenient removal of chips, so as to solve the inconvenience The effect of taking out, improving the efficiency of use, and improving the versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

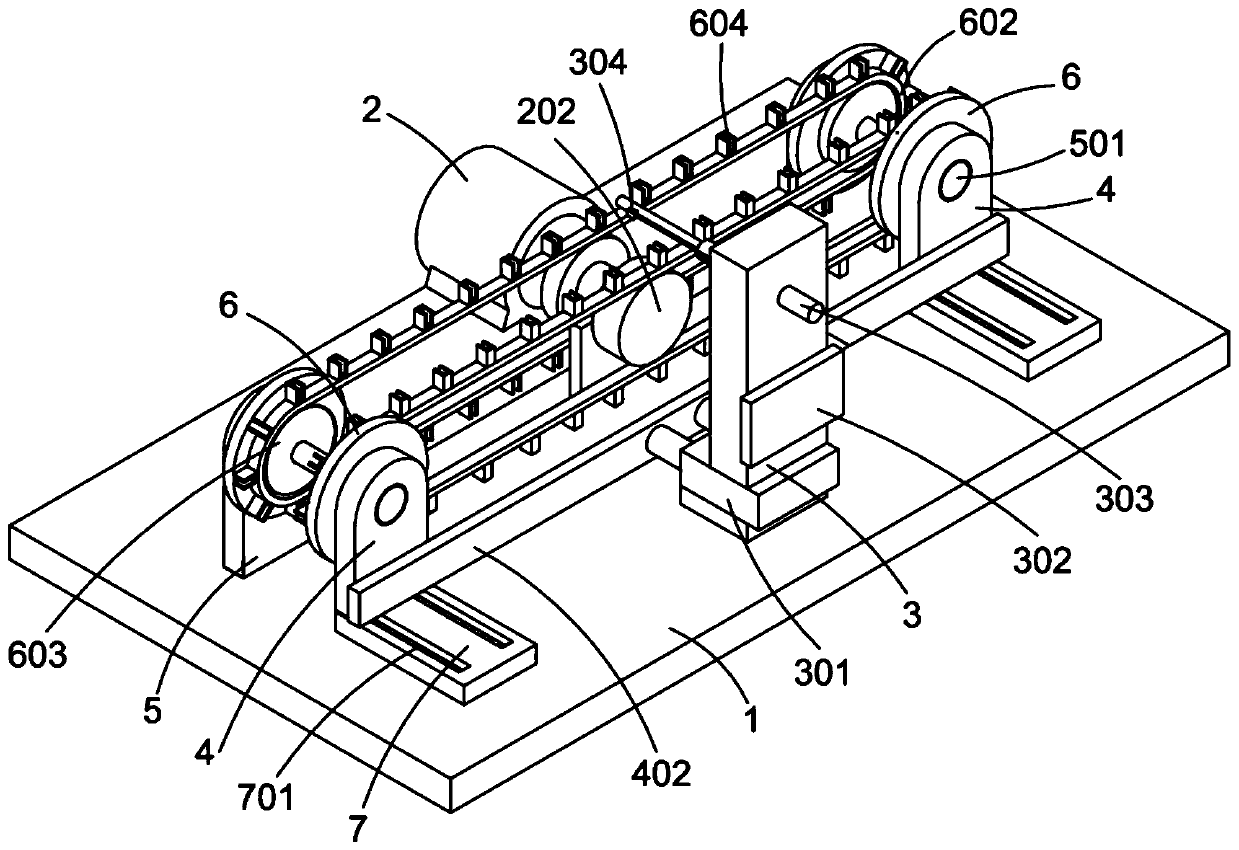

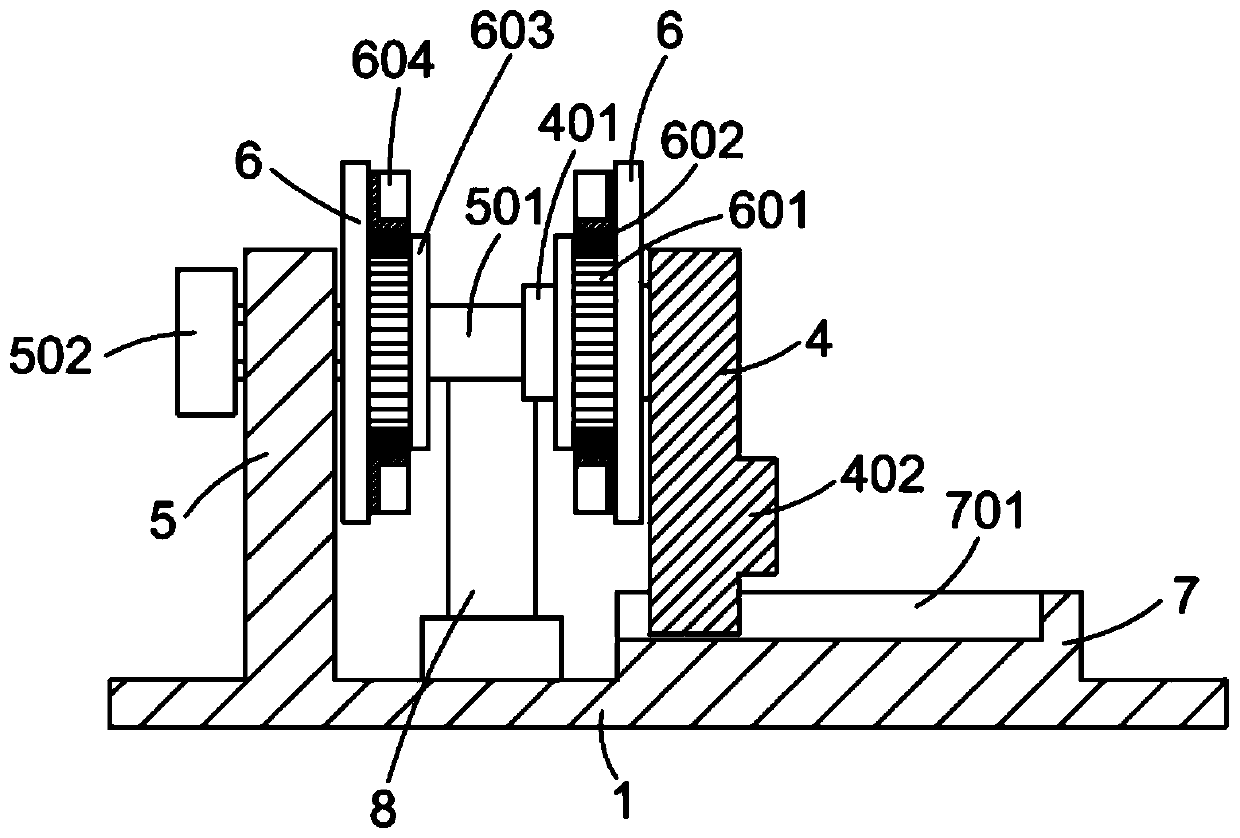

[0036] Embodiment 1: A detection method for a chip module, the detection method is based on a detection device, the detection device includes a base plate 1, a motor 2 installed on the upper surface of the base plate 1, and several fixing devices arranged at intervals on the upper surface of the base plate 1 Plate 5 and several movable plates 4 which are respectively arranged face to face with the fixed plate 5, the motor 2 is installed on the outside of the fixed plate 5 or the movable plate 4, a slide plate 7 is arranged between the base plate 1 and the movable plate 4, the The lower surface of the movable plate 4 is movably mounted on the slide plate 7, so that the movable plate 4 can move towards or away from the fixed plate 5;

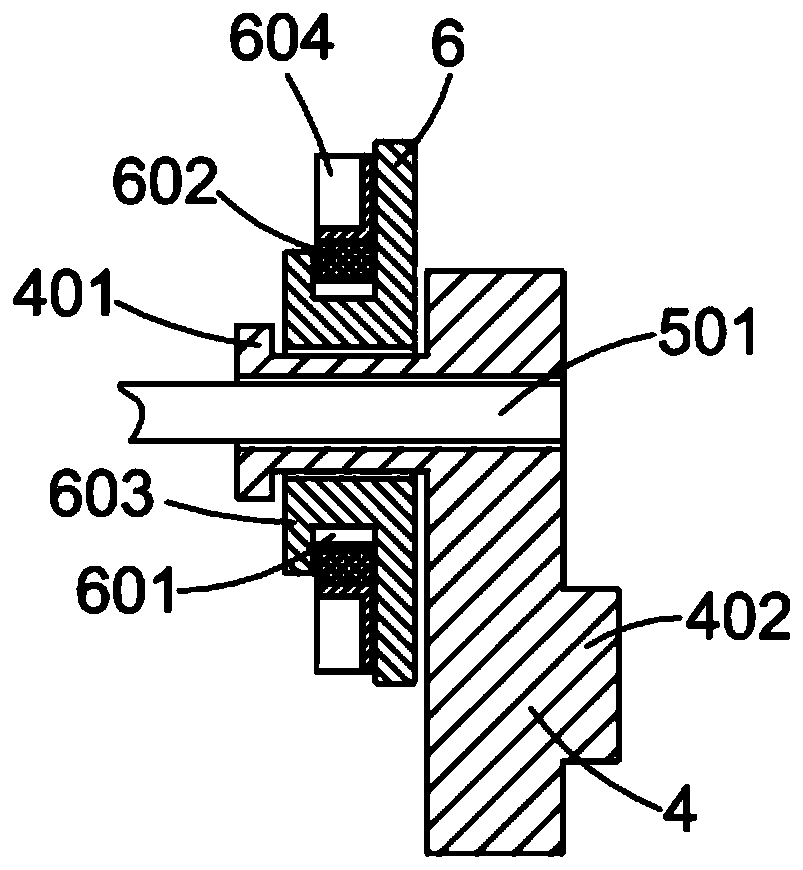

[0037] A limit shaft 501 is connected between the fixed plate 5 and the movable plate 4 which are arranged oppositely. On the side surface of the movable plate 4 close to the fixed plate 5, there is a protruding tube 401 facing the fixed plate 5. T...

Embodiment 2

[0050] Embodiment 2: A detection method of a chip module, the detection method is based on a detection device, the detection device includes a base plate 1, a motor 2 installed on the upper surface of the base plate 1, and several fixing devices arranged at intervals on the upper surface of the base plate 1 Plate 5 and several movable plates 4 which are respectively arranged face to face with the fixed plate 5, the motor 2 is installed on the outside of the fixed plate 5 or the movable plate 4, a slide plate 7 is arranged between the base plate 1 and the movable plate 4, the The lower surface of the movable plate 4 is movably mounted on the slide plate 7, so that the movable plate 4 can move towards or away from the fixed plate 5;

[0051] A limit shaft 501 is connected between the fixed plate 5 and the movable plate 4 which are arranged oppositely. On the side surface of the movable plate 4 close to the fixed plate 5, there is a convex tube 401 facing the fixed plate 5. The ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com