Elevated ground

A ground and end face technology, applied in the field of architectural decoration, can solve problems such as large influence of levelness, difficulty in controlling levelness, and easy deformation, etc., and achieve the effects of lifting control, easy adjustment, and enhanced support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

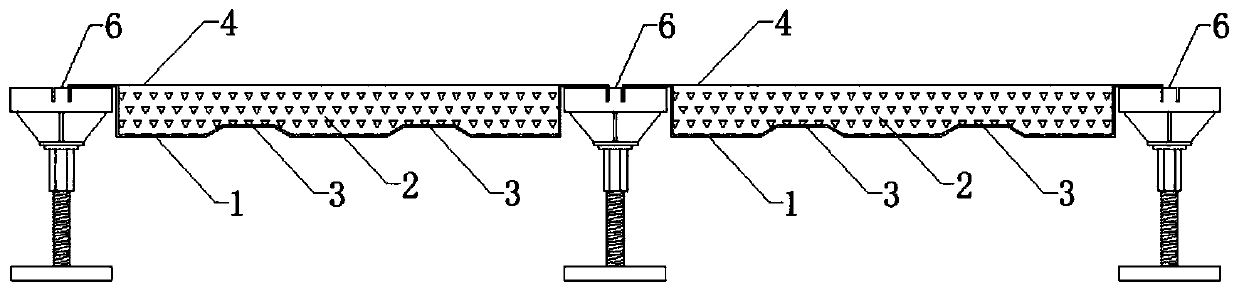

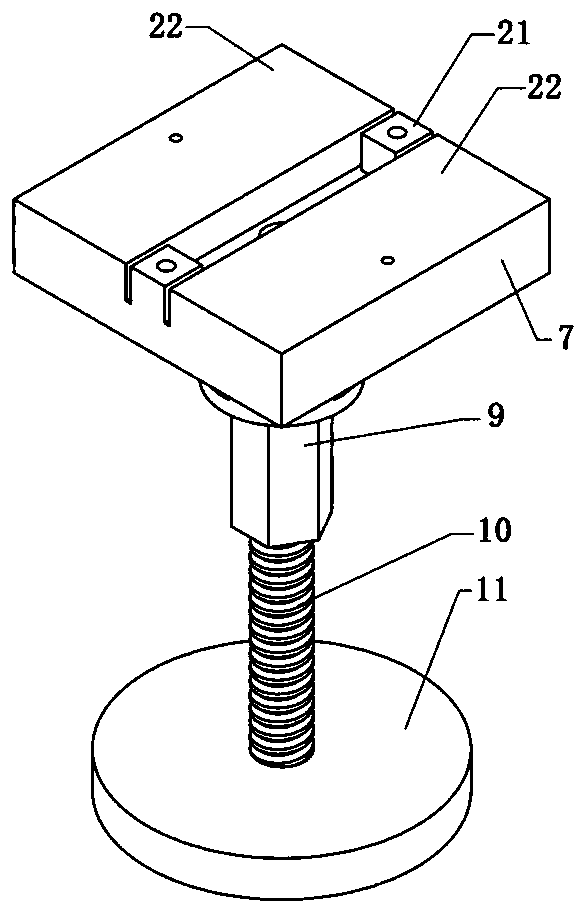

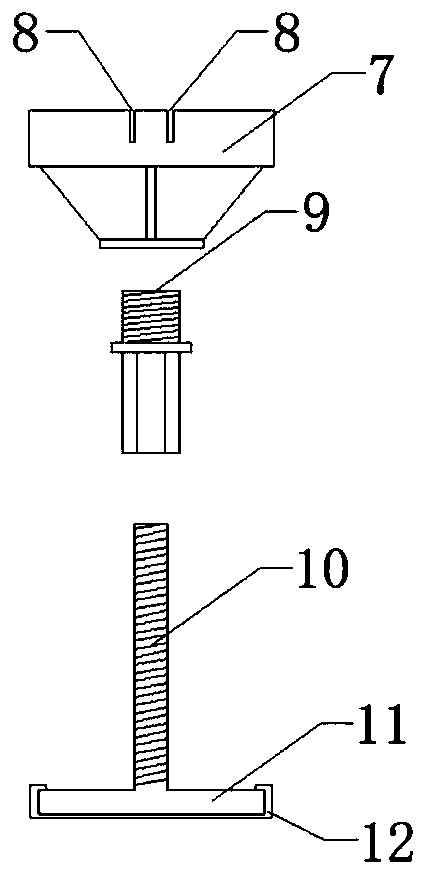

[0034] refer to Figure 1 to Figure 4 , Figure 8 to Figure 11 As shown, a raised ground includes a foot assembly 6 and an overhead board 1 connected with the foot assembly 6. The improvement is that the foot assembly 6 includes a support foot 11, a screw 10 connected with the support foot 11, and a screw 10 connected connection kit 9, the bracket 7 connected with the connection kit 9, the upper end of the connection kit 9 is provided with a threaded connection portion, the bracket 7 is provided with a connecting hole 13 passing through the bracket 7, and the connection hole 13. At least the lower part is provided with an internal thread for connecting with the threaded connection part. The connecting sleeve 9 is provided with a through hole passing through the connecting sleeve 9. At least the lower part of the through hole is provided with an internal thread for connecting with the screw rod 10. The upper end of the screw 10 is provided with a screwing part 20; the length...

Embodiment 2

[0048] On the basis of embodiment 1, with reference to Figure 2 to Figure 4 As shown, the connecting portion is two slots 8 located on the upper part of the bracket 7 and symmetrically arranged on both sides of the connecting hole 13. The outer sides of the two slots 8 are the abutting surfaces 22, The middle is a non-contact surface 21 , the contact surface 22 is not higher than the non-contact surface 21 , and the bent portion of the erection rail is inserted into the slot 8 .

[0049] Further, the width of the card slot 8 matches the thickness of the erection track, and the distance between the card slot 8 and the edge of the bracket 7 matches the width of the erection track, so that the erection track can be firmly overlapped with the foot assembly 6 and place it in the slot 8.

[0050] Further, the abutting surface 22 is provided with a deep punching hole 14 . Self-tapping screws are used to pass through the erection rail and the deep punching hole 14, so that the over...

Embodiment 3

[0053] On the basis of embodiment 1, with reference to Figure 5 , 6 As shown, the connecting portion is a card slot 8 located on the upper part of the bracket 7 and on one side of the connecting hole 13, one side of the card slot 8 is the abutment surface 22 abutting against the erection track, and the other side is the non-contact surface 22. The abutment surface 21, the abutment surface 22 is not higher than the non-abutment surface 21, a through hole is opened on the position corresponding to the connection hole 13 on the erection track, and the bending part of the erection track is snapped into card slot 8.

[0054] The eccentric clamping method of this embodiment is mainly used for floor laying near the foot of the side facade. Due to the eccentric arrangement, it can avoid the subsidence and deformation of the aerial plate 1 caused by the inclination of the support foot assembly 6 in the symmetrical arrangement. The tool can be passed through the through hole, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com