Preparation method of high-hardness polyethylene sheet for four-wheel skateboard

A polyethylene, high hardness technology, applied in the field of high hardness polyethylene sheet preparation, can solve the problems of insufficient hardness, low impact resistance, fracture, etc., to improve rigidity and crushing performance, wear resistance and increase the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

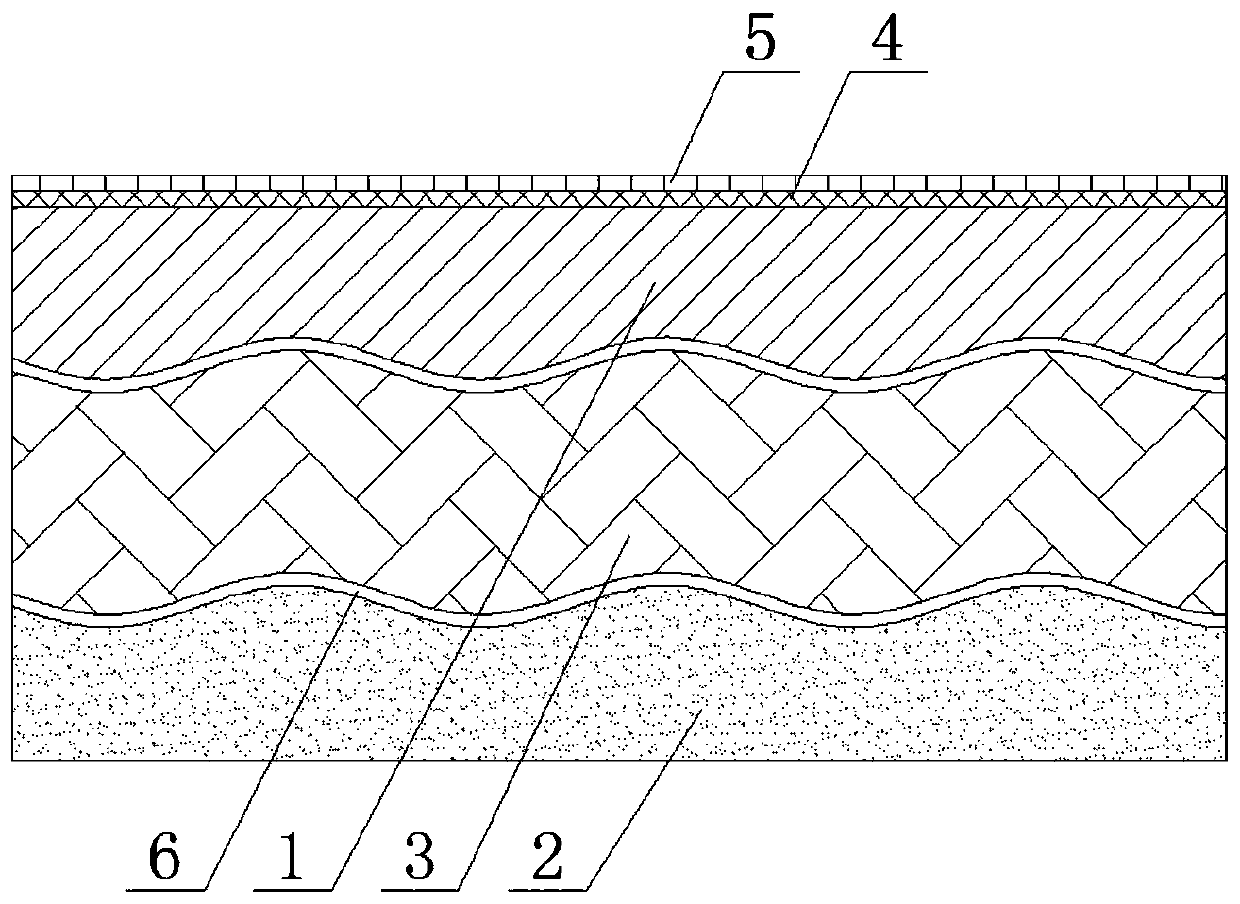

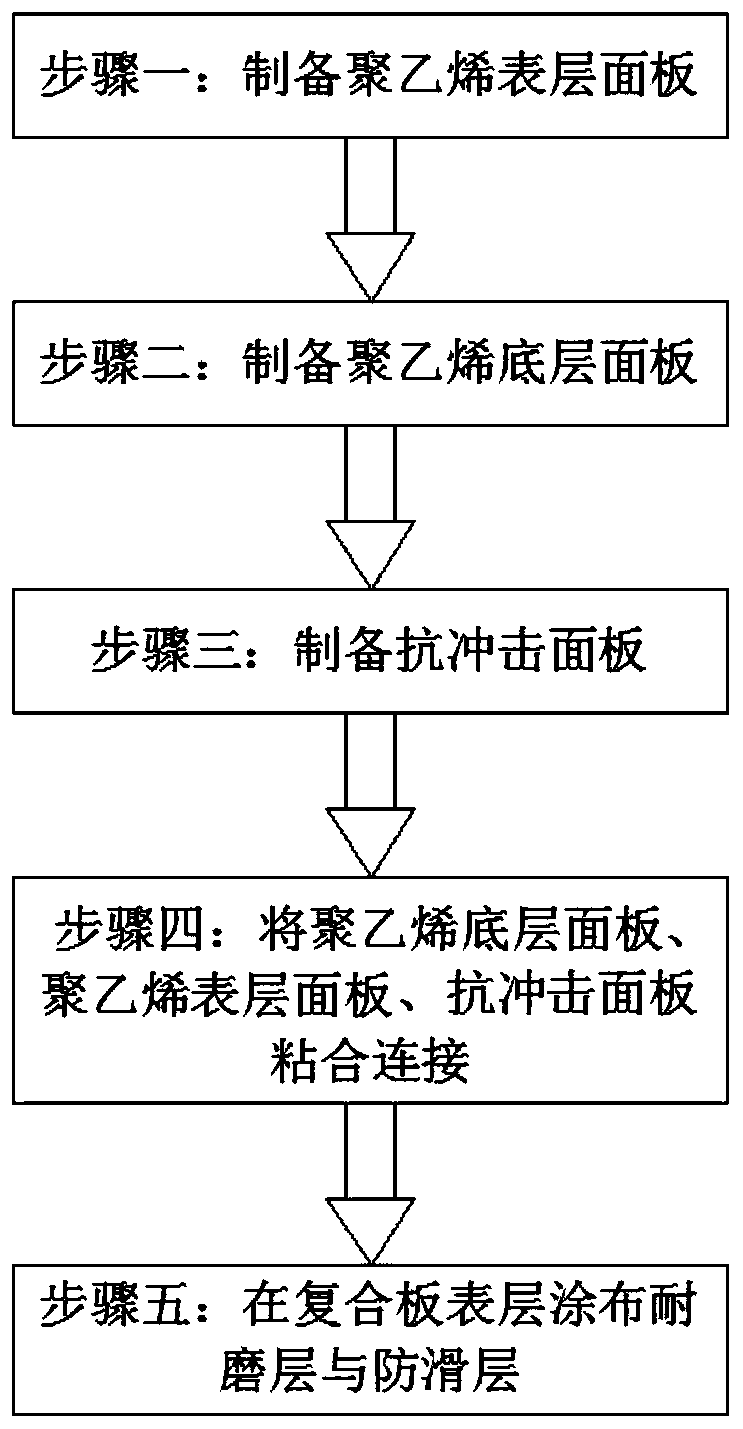

[0025] see Figure 1-2 , a high-hardness polyethylene sheet for four-wheel skateboards, comprising a polyethylene surface panel 1 and a polyethylene bottom panel 2, an impact-resistant panel 3 is arranged between the polyethylene surface panel 1 and the polyethylene bottom panel 2, and the anti-shock The impact panel 3 is arranged in a wave-like structure, and the polyethylene surface panel 1 and the polyethylene bottom panel 2 are fixed and adhered to the upper and lower surfaces of the impact-resistant panel 3 through an adhesive 6, and the polyethylene surface panel 1 and the polyethylene bottom panel 2 are opposite to each other. One side is correspondingly set as a corrugated structure surface, the upper surface layer of the polyethylene surface layer panel 1 is provided with a wear-resistant layer 4, and the upper part of the wear-resistant layer 4 is provided with an anti-slip layer 5; wherein the polyethylene surface layer panel 1 is prepared from the following raw mate...

Embodiment 2

[0031]A high-hardness polyethylene sheet for four-wheeled skateboards, comprising a polyethylene surface panel 1 and a polyethylene bottom panel 2, an impact-resistant panel 3 is arranged between the polyethylene surface panel 1 and the polyethylene bottom panel 2, and is impact-resistant The panel 3 is arranged in a wave-like structure, and the polyethylene surface panel 1 and the polyethylene bottom panel 2 are fixed and adhered to the upper and lower surfaces of the impact-resistant panel 3 through an adhesive 6, and the polyethylene surface panel 1 and the polyethylene bottom panel 2 are opposite to each other. The side surface is correspondingly set as a corrugated structure surface, the upper surface layer of the polyethylene surface layer panel 1 is provided with a wear-resistant layer 4, and the upper part of the wear-resistant layer 4 is provided with an anti-skid layer 5; wherein the polyethylene surface layer panel 1 is prepared from the following raw materials by wei...

Embodiment 3

[0037] A high-hardness polyethylene sheet for four-wheeled skateboards, comprising a polyethylene surface panel 1 and a polyethylene bottom panel 2, an impact-resistant panel 3 is arranged between the polyethylene surface panel 1 and the polyethylene bottom panel 2, and is impact-resistant The panel 3 is arranged in a wave-like structure, and the polyethylene surface panel 1 and the polyethylene bottom panel 2 are fixed and adhered to the upper and lower surfaces of the impact-resistant panel 3 through an adhesive 6, and the polyethylene surface panel 1 and the polyethylene bottom panel 2 are opposite to each other. The side surface is correspondingly set as a corrugated structure surface, the upper surface layer of the polyethylene surface layer panel 1 is provided with a wear-resistant layer 4, and the upper part of the wear-resistant layer 4 is provided with an anti-skid layer 5; wherein the polyethylene surface layer panel 1 is prepared from the following raw materials by we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com