A production process of bearing roller warm forging

A production process and technology of bearing rollers, applied in the field of warm forging production process of bearing rollers, can solve the problems of insufficiently compact bearing rollers, low material utilization rate, time-consuming and labor-intensive, etc., and achieve high production efficiency and high material utilization rate. , to avoid the effect of maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

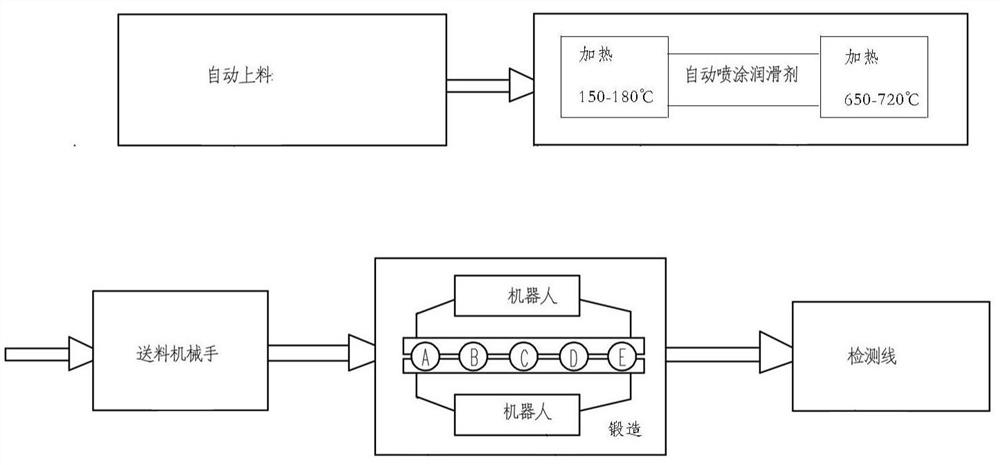

[0032] A bearing roller temperature forging production process, the specific steps are as follows:

[0033] a) Feeding steel bars into the heating furnace;

[0034] b) Spray lubricants to steel bars and continue to heat;

[0035] c) Multi-station forging at 700 ° C;

[0036] d) Forged surface quality for testing;

[0037] e) grinding after quenching;

[0038] f) Enter the detection line detection.

[0039] Further improvements in the present invention are, step a), to feed the steel bar to the electric heating furnace to be applied, and the heating 150-180 ° C is released in order.

[0040] Further improvements of the present invention are, step b), and the workpiece steel bar is sprayed, and heated from 650 to 720 ° C.

[0041] Further improvements in the present invention are in step c), and the specific steps are:

[0042] , The robot is sent vertically into the cavity A, one end for forwarding the boss and the other end for forwarding the circle;

[0043] The robot flips t...

Embodiment 2

[0049] A bearing roller temperature forging production process, the specific steps are as follows:

[0050] a) Feeding steel bars into the heating furnace;

[0051] b) Spray lubricants to steel bars and continue to heat;

[0052] c) Multi-station forging at 720 ° C;

[0053] d) Forged surface quality for testing;

[0054] e) grinding after quenching;

[0055] f) Enter the detection line detection.

[0056] Further improvements in the present invention are, step a), to feed the steel bar to the electric heating furnace to be applied, and the heating 150-180 ° C is released in order.

[0057] Further improvements of the present invention are, step b), and the workpiece steel bar is sprayed, and heated from 650 to 720 ° C.

[0058] Further improvements in the present invention are in step c), and the specific steps are:

[0059] , The robot is sent vertically into the cavity A, one end for forwarding the boss and the other end for forwarding the circle;

[0060] The robot flips t...

Embodiment 3

[0066] A bearing roller temperature forging production process, the specific steps are as follows:

[0067] a) Feeding steel bars into the heating furnace;

[0068] b) Spray lubricants to steel bars and continue to heat;

[0069] c) Multi-station forging at 720 ° C;

[0070] d) Forged surface quality for testing;

[0071] e) grinding after quenching;

[0072] f) Enter the detection line detection.

[0073] Further improvements in the present invention are, step a), to feed the steel bar to the electric heating furnace to be applied, and the heating 150-180 ° C is released in order.

[0074] Further improvements of the present invention are, step b), and the workpiece steel bar is sprayed, and heated from 650 to 720 ° C.

[0075] Further improvements in the present invention are in step c), and the specific steps are:

[0076] , The robot is sent vertically into the cavity A, one end for forwarding the boss and the other end for forwarding the circle;

[0077] The robot flips t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com