A method for identifying consistency of material

A consistent and consistent technology, applied in the field of identifying the consistency of materials, can solve the problems of unrecognizable additives, difficult to help identify different materials, difficult to provide full component analysis of plastics, etc., to eliminate hidden dangers and ensure the quality of parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0075]Three samples A, B and C are provided to be compared. Sample C as a standard sample is provided by the raw material supplier, which is made of a specific PC-ABS, while samples A and B as samples to be tested are respectively taken from the warehouse of the automobile factory and prepared for assembly The plastic parts of the new car and the plastic parts from the parts factory that have not yet been sent to the warehouse of the automobile factory, these two samples A and B claim to be made of the same material as sample C PC-ABS.

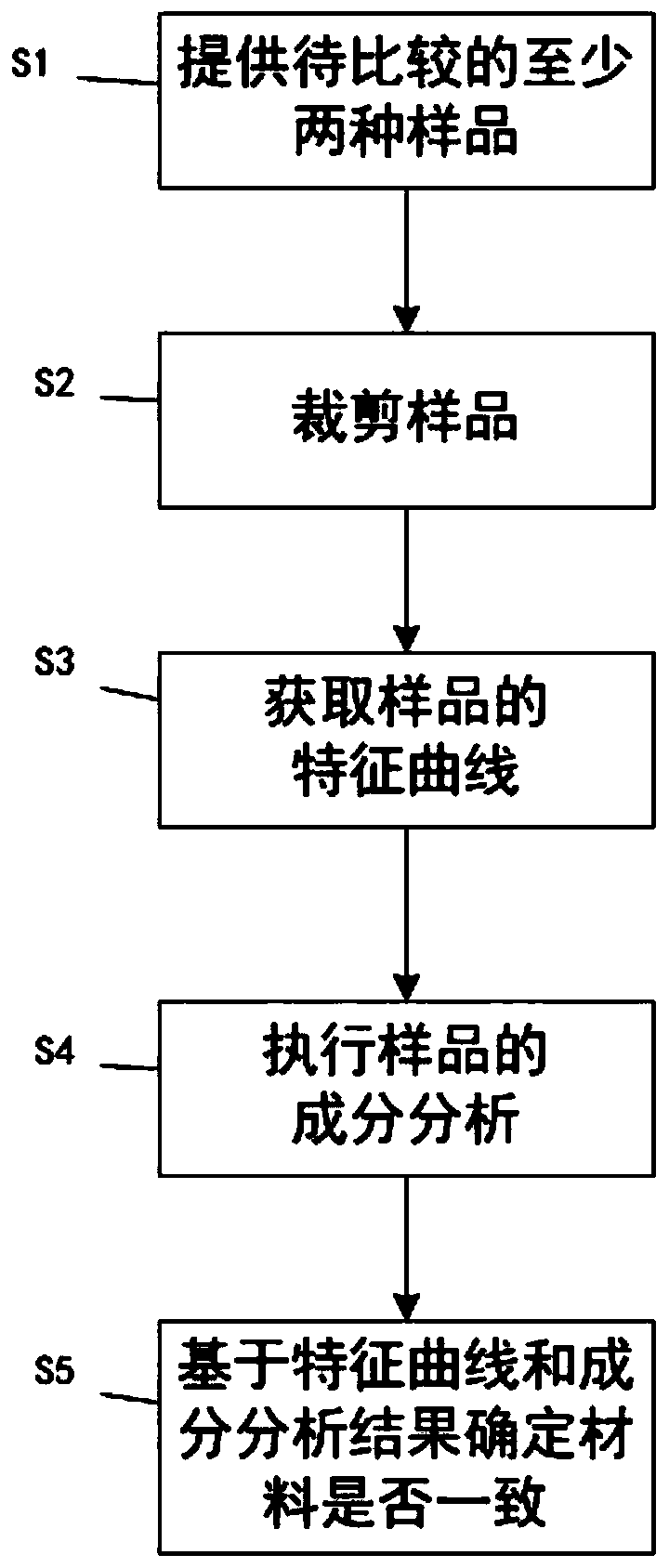

[0076] Next, use the method according to the invention to identify whether the materials of samples A, B and C are highly consistent.

[0077] First, samples A, B, and C are cut so that the size of the cut samples meets the size requirements of the subsequent testing equipment.

[0078] Then, samples A, B, and C were respectively put into a Fourier transform infrared spectrometer to perform infrared spectrum analysis, thereby obtaining respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com