Drying system for kitchen waste treatment

A drying system and kitchen waste technology, which is applied in the field of drying system for food waste treatment, can solve the problems that affect the classification and recycling of solid waste, accelerate the decomposition of solid waste, and make it difficult to dry completely, so as to reduce energy consumption , increase water absorption, reduce the effect of drying cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

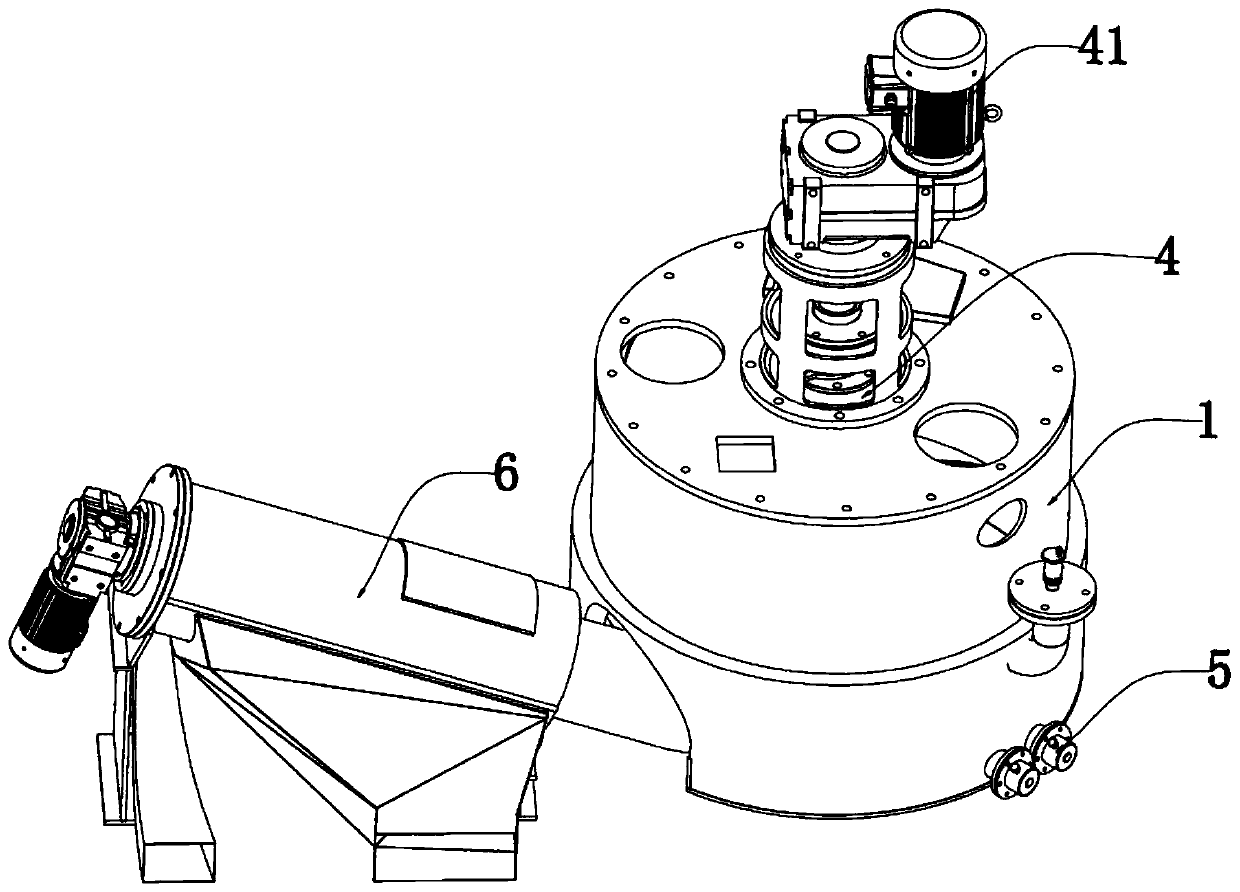

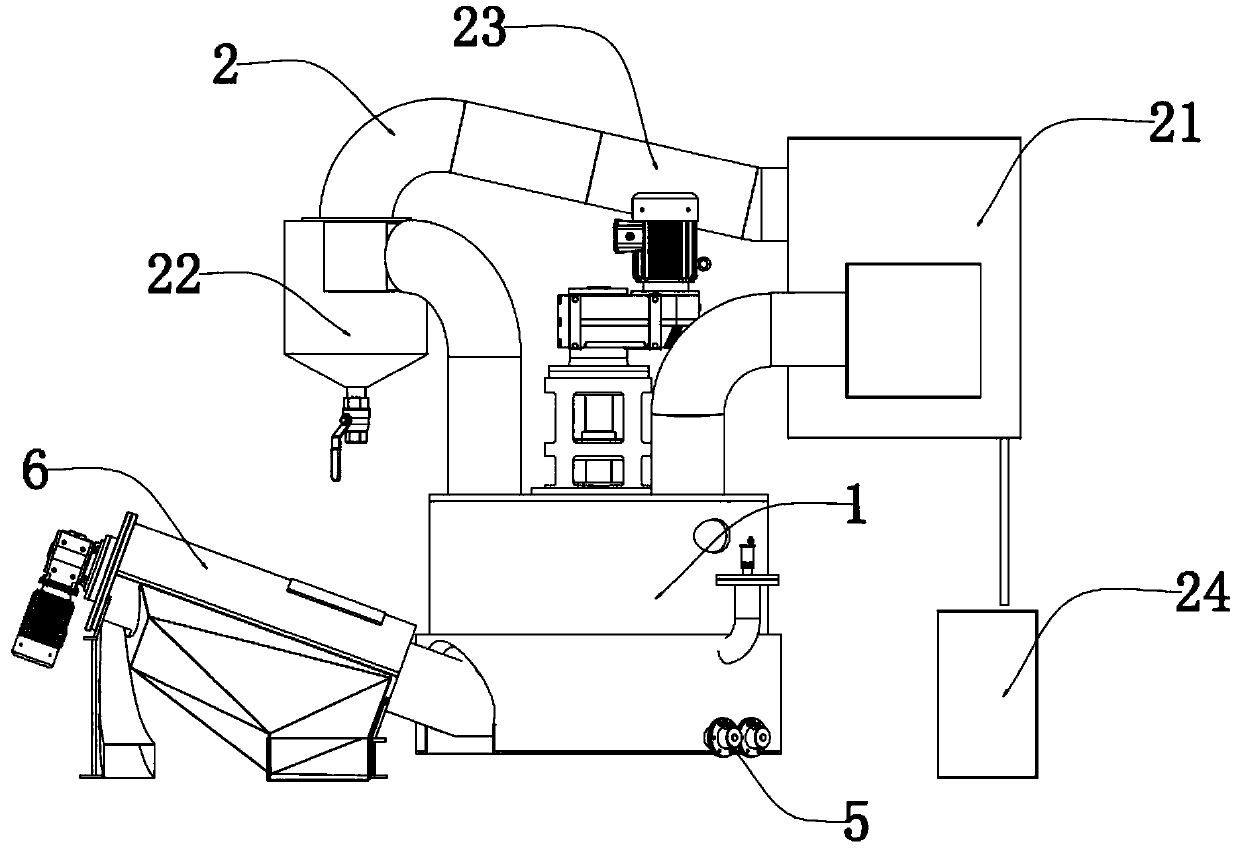

[0035] Please refer to Figure 1-Figure 3 , the present invention provides a drying system for food waste treatment, comprising:

[0036] The drying container 1 has a drying chamber in the drying container 1; the drying chamber is used to hold solid waste containing moisture;

[0037] The first drying circulation pipeline 2, the first drying circulation pipeline 2 communicates with the drying chamber, the first drying circulation pipeline 2 is provided with a first drying condensing assembly 21 and a first fan;

[0038] The second drying circulation pipeline 3, the second drying circulation pipeline 3 communicates with the drying chamber, the second drying circulation pipeline 3 is provided with a second drying condensing assembly and a second fan 32;

[0039] Stirring component 4, the stirring com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com