Use method of absorbed recycle acid waste heat in sulfuric acid process

A technology of absorption cycle and process, applied in heating methods, cooling fluid circulation devices, applications, etc., can solve problems such as waste of water resources and insufficient utilization of waste heat, and achieve the effect of widespread application value, significant direct benefits and ecological benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

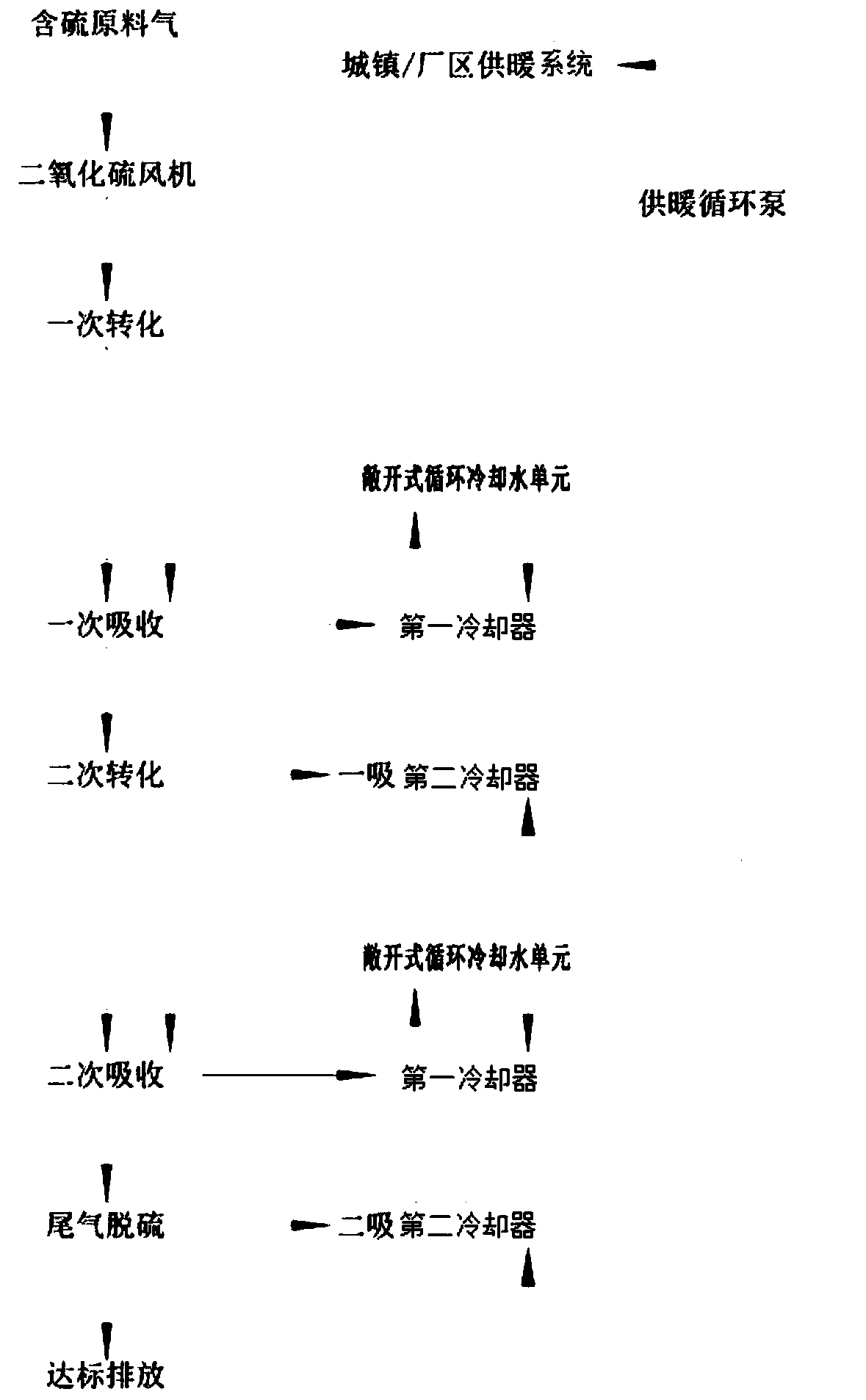

Image

Examples

Embodiment

[0014] The acid inlet temperature of the first cooler 1# is 100°C, the acid outlet temperature is 78°C, the acid inlet temperature of the first cooler 2# is 87°C, the acid outlet temperature is 75°C, the inlet water temperature of the cold side is 28°C, and the outlet water temperature is 35°C, open The inlet water temperature of the cooling water tower of the type circulating cooling water unit is 35°C, and the outlet water temperature after cooling is 28°C. The cold side inlet water (heating water) Return water) temperature is 45°C, cold side outlet water (heating water supply) temperature is 60°C. The heat removal task of the absorption cycle acid is completed by the first cooler and the open circulation cooling water unit in the non-heating period, and is completed by the second cooler, heating circulation pump and town / factory heating system in the heating period, and the absorption acid is realized synchronously use of excess heat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com