Solid waste garbage disposal method

A technology for waste disposal and waste, which is applied in the direction of combustion method, grain treatment, combustion type, etc., can solve the problems of wasting time, slow burning speed, etc., and achieve the effect of increasing the intensity value, realizing reuse, and realizing waste utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

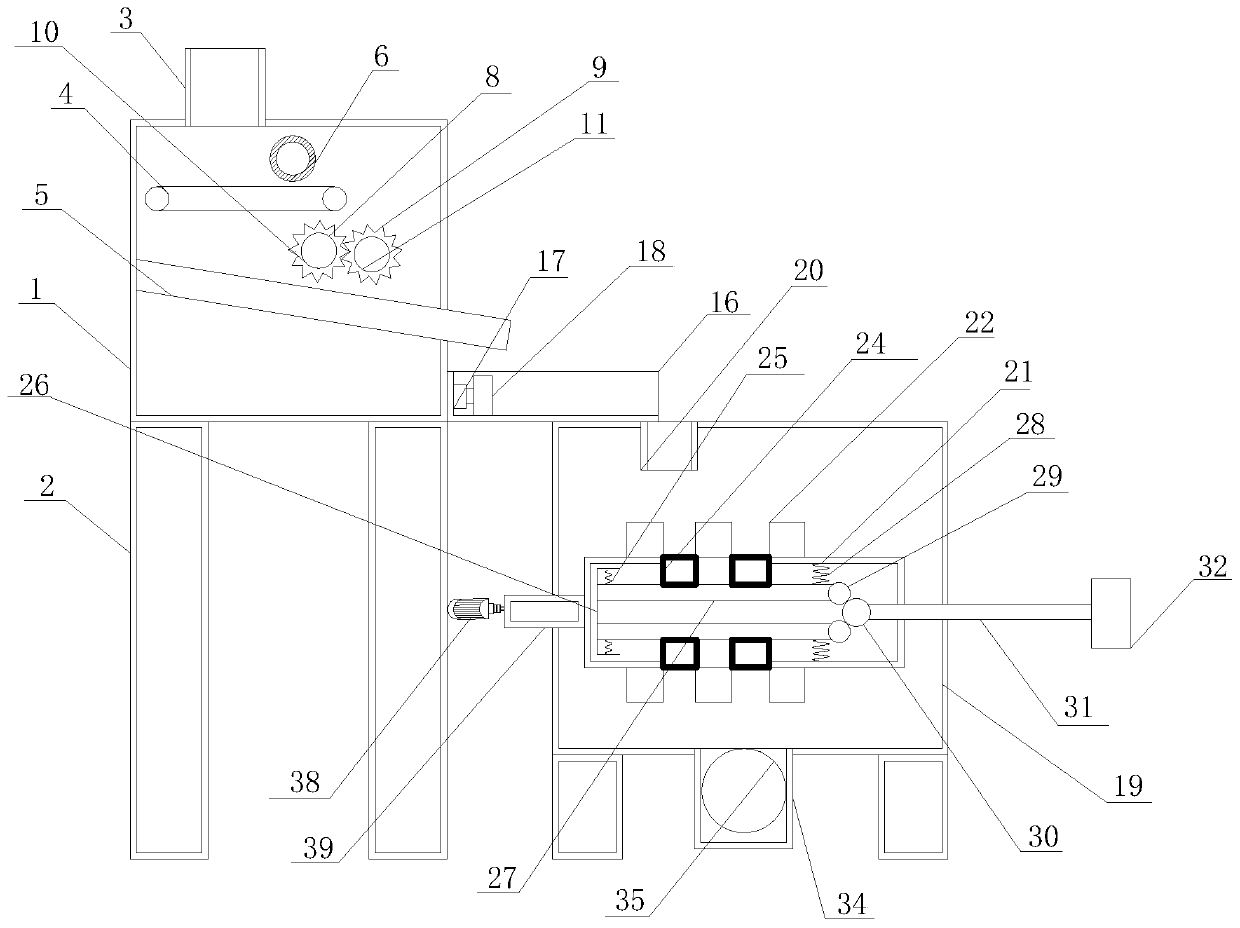

[0028] see Figure 1-4 , the present invention provides a technical solution:

[0029] A method for treating solid waste, comprising the steps of:

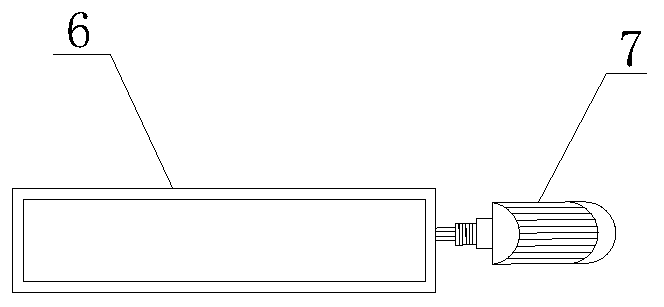

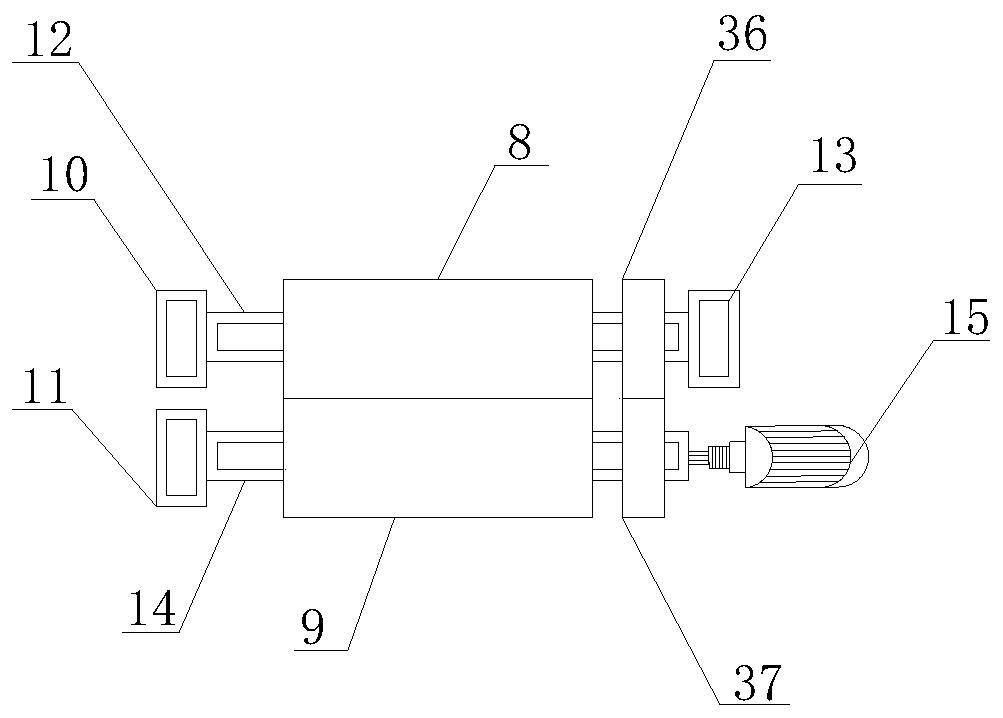

[0030] S1: First put the sorted combustible garbage into the conveying device 4, use the pressure roller 6 to flatten the garbage, and the flattened garbage enters between the left crushing roller 8 and the right crushing roller 9 for crushing;

[0031] S2: The broken garbage passes through the material plate 5 until it enters the closing box 16, and the electric telescopic rod 17 is activated to make the push plate 18 push the broken garbage into the incinerator 19 for incineration;

[0032] S3: start the third drive motor 38 to rotate the cylinder 21, so that the stirring rod 22 is stirred inside the incinerator 19 to speed up the incineration speed. After the incineration is completed, the valve 35 is opened, and finally the incinerated matter comes out from the discharge port 34;

[0033]The garbage treatment equipment used ...

Embodiment 2

[0036] Compared with embodiment 1, embodiment 2 only increases step S4 and step S5 after step S3, and other content is identical with embodiment 1, namely

[0037] A method for treating solid waste, comprising the steps of:

[0038] S1: First put the sorted combustible garbage into the conveying device 4, use the pressure roller 6 to flatten the garbage, and the flattened garbage enters between the left crushing roller 8 and the right crushing roller 9 for crushing;

[0039] S2: The broken garbage passes through the material plate 5 until it enters the closing box 16, and the electric telescopic rod 17 is activated to make the push plate 18 push the broken garbage into the incinerator 19 for incineration;

[0040] S3: Start the third drive motor 38 to rotate the cylinder 21, so that the stirring rod 22 is stirred inside the incinerator 19 to speed up the incineration speed. After the incineration is completed, the valve 35 is opened, and finally the incinerated matter comes ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com