Clean room rotating channel capable of isolating air from communication

A technology that blocks air and clean rooms, and is applied in pipeline layout, special buildings, small buildings, etc., and can solve problems such as mutual intrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

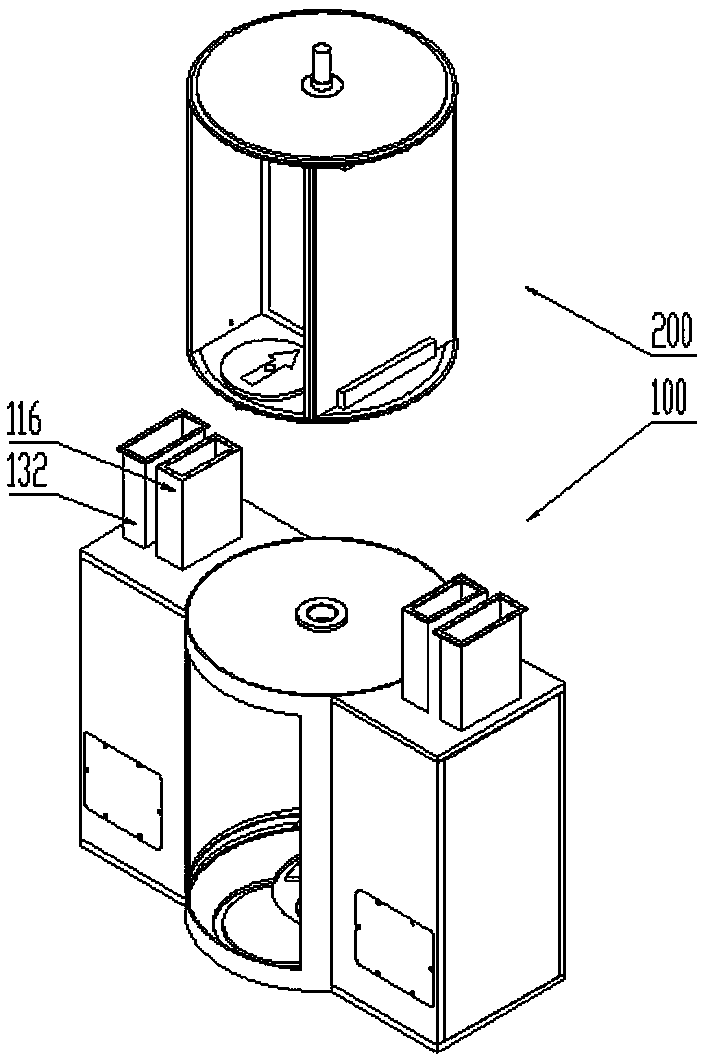

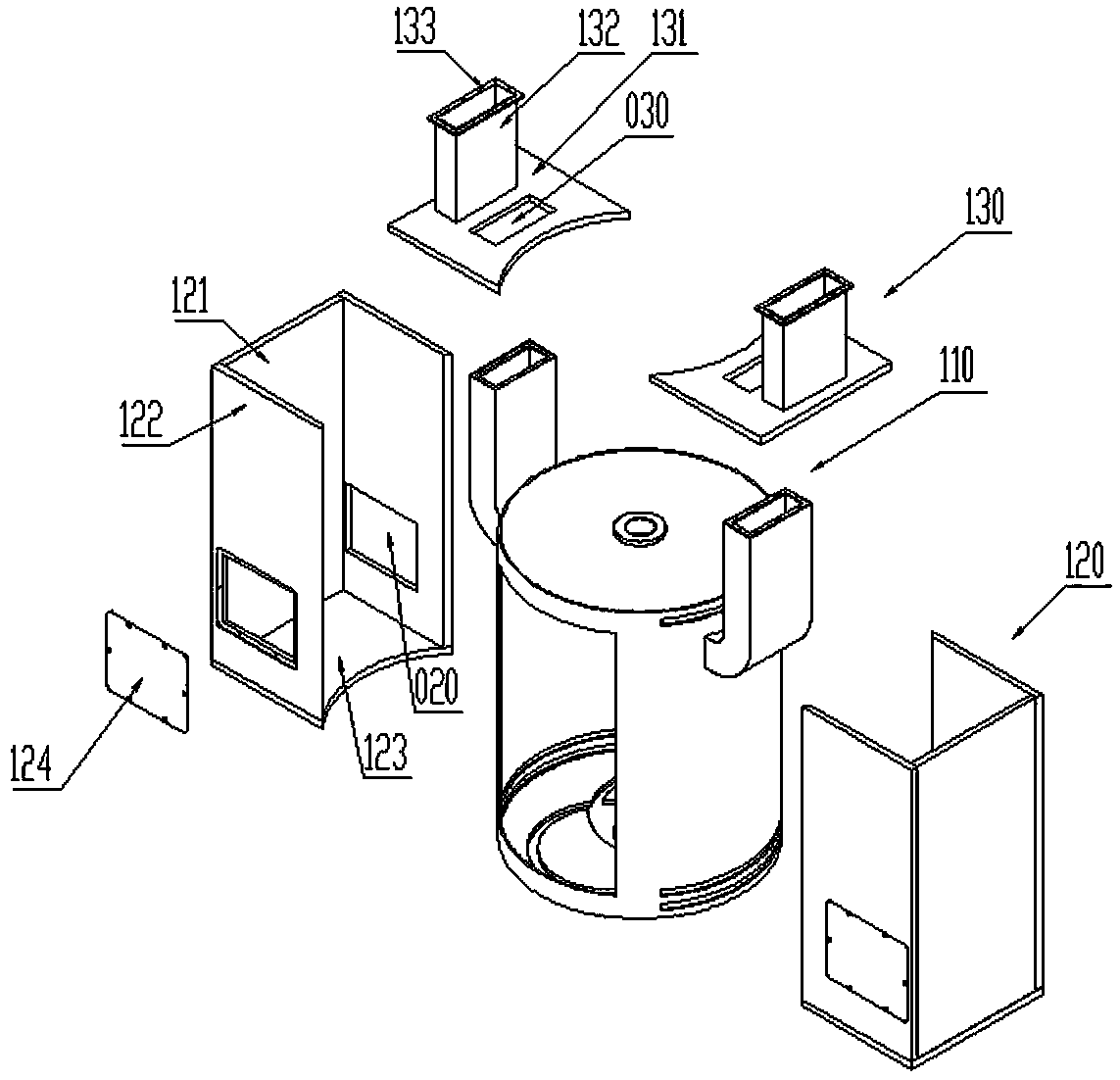

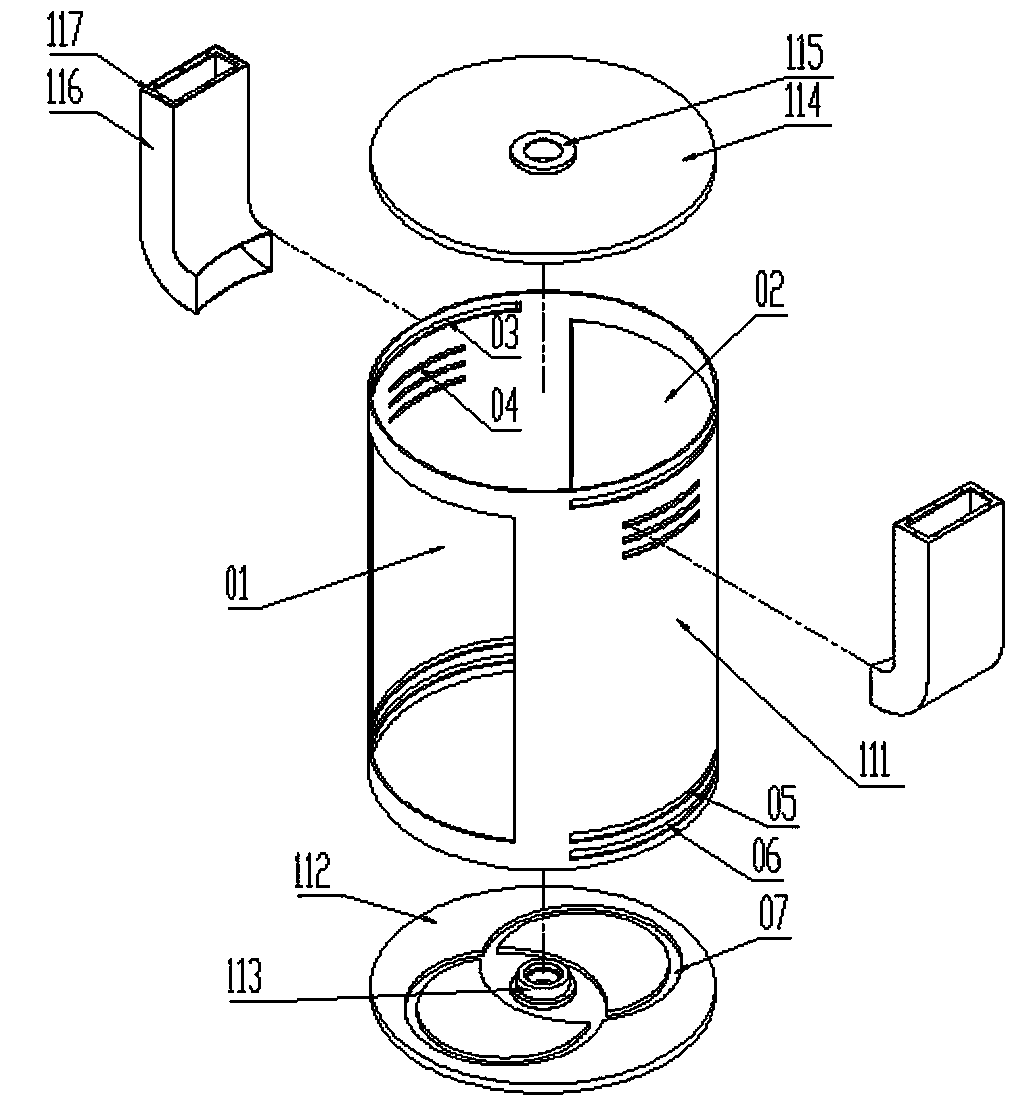

[0056] A clean room rotating tunnel with barrier air collusion, including PLC control cabinet, see figure 1 , including a cylindrical base body 100 and a manned rotary unit 200; see figure 2 , Figure 8 and Figure 9 , the cylindrical base body 100 includes a cylindrical body unit 110 and a negative pressure chamber 3 sealed on both sides of the cylindrical body unit 110, and a suction pipe 132 is arranged on the top of the negative pressure chamber 3; see image 3 The cylinder unit 110 includes a cylinder body 111 and an air inlet pipe 116, and the air inlet pipe 116 is integrally sealed and fixed on the upper part of the cylinder wall on the left and right sides of the periphery of the cylinder body 111; The passage opening includes the front passage opening 01 and the rear passage opening 02. Taking the axial section of the cylinder 111 facing the passage opening as the reference projection plane, the projection of the front passage opening 01 on the reference projection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com