A kind of preparation method of high-strength saddle shell

A high-strength, saddle technology, which is applied in the field of auto parts manufacturing, can solve the problems of difficult stamping, low material surface hardness, and increased input costs, and achieve increased strength and wear resistance, strong comprehensive mechanical properties, and reduced material costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

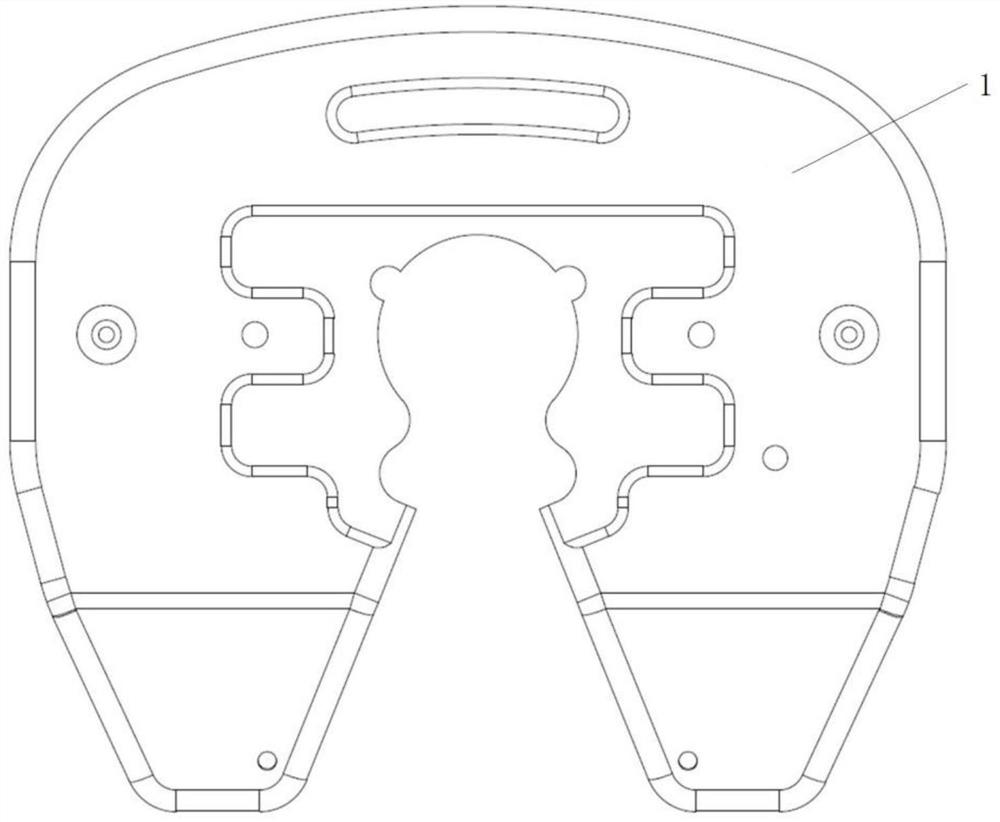

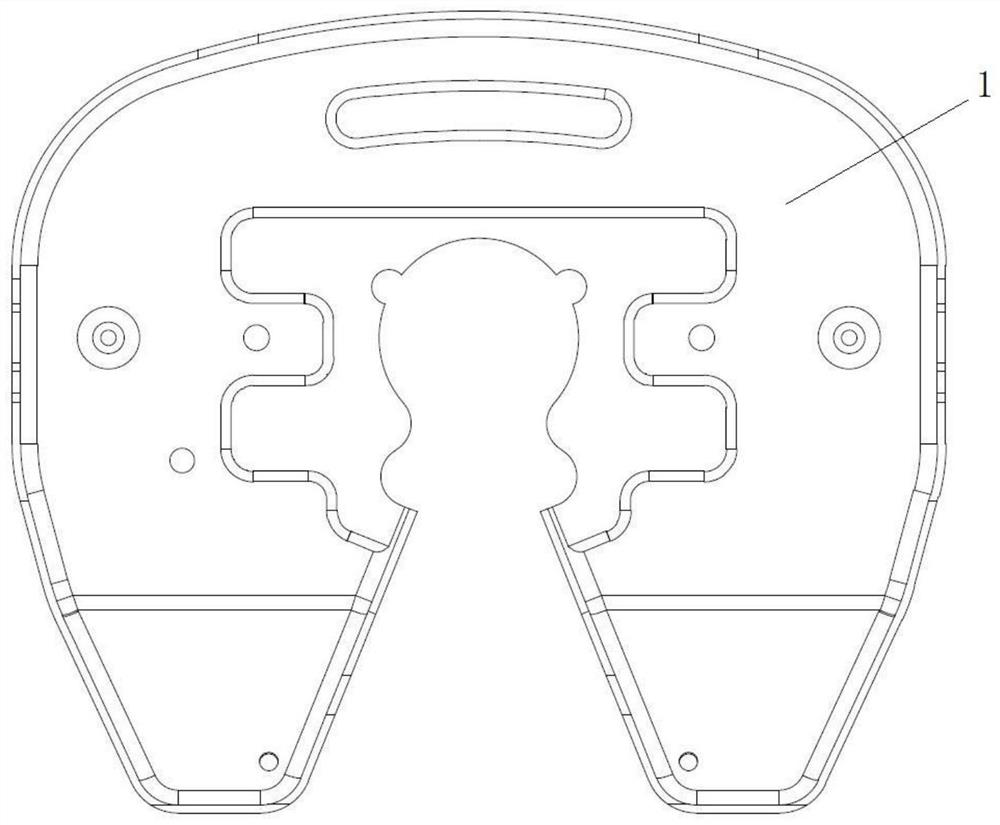

[0038] Such as figure 1 and figure 2 Shown is the saddle shell of this embodiment, and a preparation method of a high-strength saddle shell of this embodiment includes the following steps:

[0039] Step 1) material selection: the mass percentage of the chemical composition of the steel is: C: 0.2, Mn: 1.1, Si: 0.2, B: 0.002, the rest is Fe and unavoidable impurities, and the thickness of the plate is 6mm;

[0040] Step 2) flat plate stamping forming: using the selected steel according to the conventional stamping process to prepare a saddle shell body with a set shape and size;

[0041] Step 3) Bending and flanging: According to the conventional production process, the edge of the saddle shell is bent to make the size meet the technical requirements, and the formed saddle shell 1 is obtained;

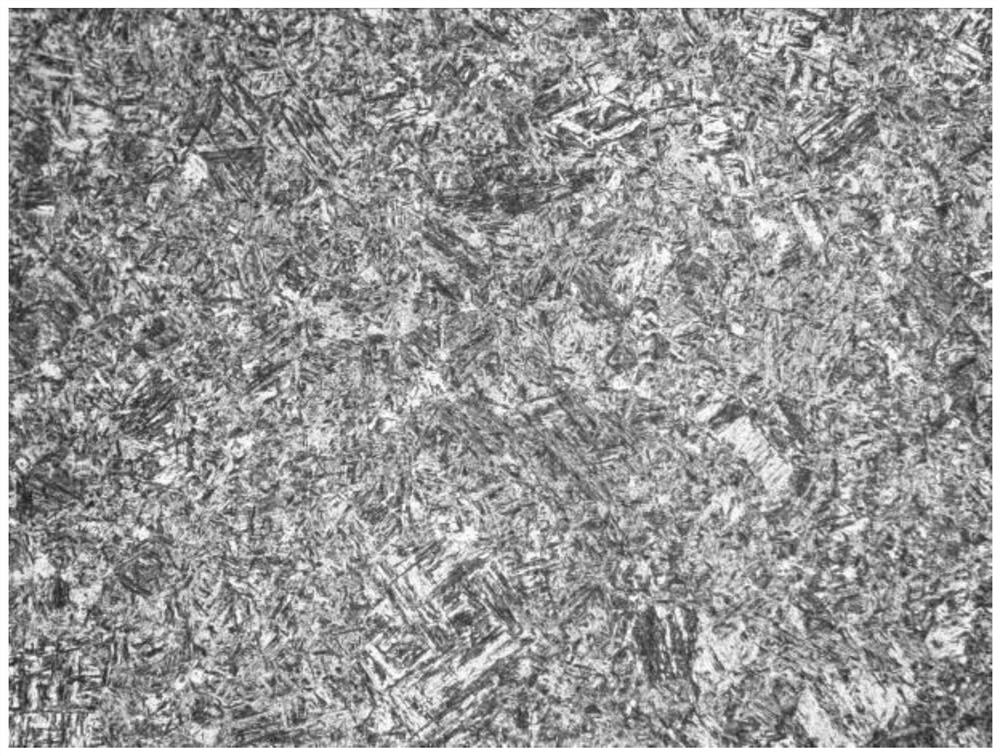

[0042] Step 4) Quenching: place the formed saddle shell 1 in a place where the protective gas N 2 Heating is carried out in a continuous furnace. In order to make the shell evenly hea...

Embodiment 2

[0048] A method for preparing a high-strength saddle shell of this embodiment includes the following steps:

[0049] Step 1): material selection: the mass percentage of the chemical composition of the steel is: C: 0.3, Mn: 1.4, Si: 0.3, B: 0.0035, the rest is Fe and unavoidable impurities, and the thickness of the plate is 6mm;

[0050] Step 2) flat plate stamping forming: using the selected steel according to the conventional stamping process to prepare a saddle shell body with a set shape and size;

[0051] Step 3) Bending and flanging: According to the conventional production process, the edge of the saddle shell is bent to make the size meet the technical requirements, and the formed saddle shell 1 is obtained;

[0052] Step 4) Quenching: place the formed saddle shell 1 in a place where the protective gas N 2 Heating is carried out in a continuous furnace. In order to make the shell evenly heated and reduce the deformation after heat treatment, the heating process adopts ...

Embodiment 3

[0058] A method for preparing a high-strength saddle shell of this embodiment includes the following steps:

[0059] Step 1): material selection: the mass percentage of the chemical composition of the steel is: C: 0.23, Mn: 1.2, Si: 0.23, B: 0.003, the rest is Fe and unavoidable impurities, and the thickness of the plate is 6mm;

[0060] Step 2) flat stamping forming: using the selected steel to prepare a saddle shell with a set shape and size according to a conventional stamping process;

[0061] Step 3) Bending and flanging: According to the conventional production process, the edge of the saddle shell is bent to make the size meet the technical requirements, and the formed saddle shell 1 is obtained;

[0062] Step 4) Quenching: Place the formed saddle shell 1 in a continuous furnace with protective gas N2 for heating. In order to make the shell evenly heated and reduce the deformation after heat treatment, the heating process adopts segmental heating. First heat the saddle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com