U-shaped structure uranium washing device and method

A leaching device, U-shaped technology, applied in the field of uranium ore in-situ leaching, can solve problems such as difficult operation and control, large land occupation and investment, resin poisoning, etc., achieve automatic control and precise control, and reduce safety and environmental protection pressure , The effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

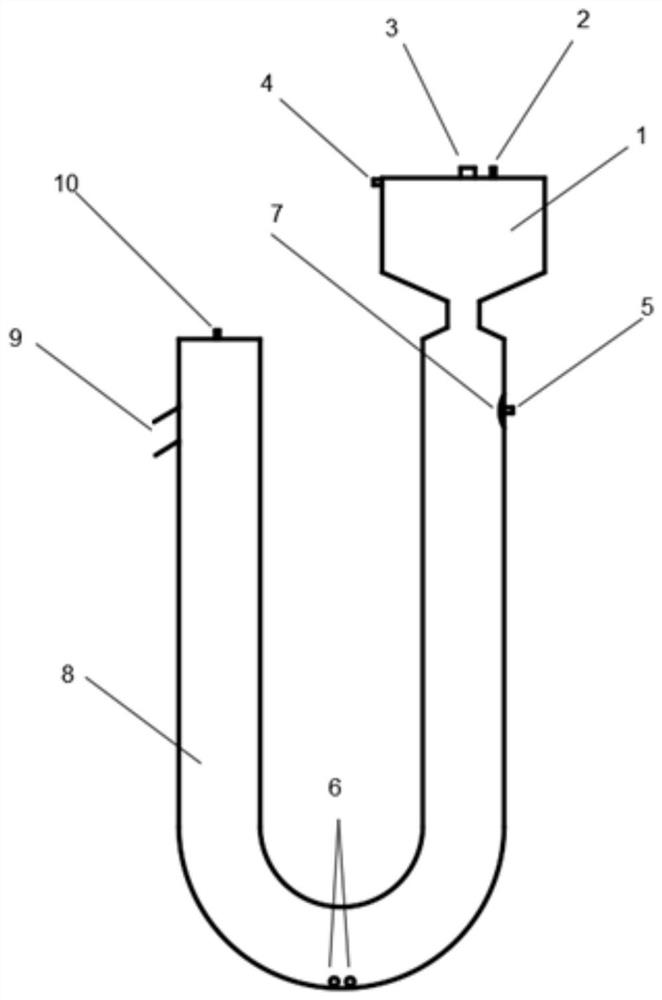

[0028] A U-shaped structure uranium leaching device, comprising a U-shaped structure tower body 8 and a resin storage tank 1, and the left end of the U-shaped structure tower body 8 is provided with a lean resin outlet 9 and an eluent inlet 10;

[0029] The upper right end of the U-shaped structure tower body 8 is connected to a resin storage tank 1. The resin storage tank 1 has a compressed air inlet 2, a primary saturated resin inlet 3, and an overflow port 4. The right end of the U-shaped structure has a tail liquid outlet 5 and tail liquid outlet 5. There is a filter 7 on it;

[0030] There is a qualified liquid outlet 6 at the bottom of the U-shaped structure;

[0031] A U-shaped structure uranium leaching method, comprising the following steps:

[0032] S1: Add the resin into the tower from the primary saturated resin inlet 3, the inlet resin is D231YT, the adsorption capacity is 14mg / mLWR, and the lean resin outlet 9 is opened.

[0033] S2: Open the eluent inlet 10 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com