Method for producing high-octane aromatic gasoline by alkylation of benzene and methanol

A high-octane, aromatic gasoline technology, applied in chemical instruments and methods, processing hydrocarbon oil, refining hydrocarbon oil, etc., can solve complex alkylation reaction process, low selectivity of methanol alkylation, and catalyst deactivation rate Fast and other problems, to achieve the effect of reducing the coking deactivation rate, long activity stability time, and long stable operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1: the preparation of extruded catalyst

[0063] Weigh 10g of SiO respectively 2 / Al 2 o 3 32 HZSM-5 molecular sieve raw powder, 55g gibbsite, 35g cerium nitrate hexahydrate, stir and mix the three for 15min to obtain a solid mixture; add 3g of squash powder to the solid mixture, stir and mix for 15min, then add 20g of deionized water, and stirred and mixed for 15min; then, while stirring, 106g of dilute nitric acid aqueous solution with a mass fraction of 5% was added dropwise, and the mixture was kneaded into a mud mass, which was formed and extruded by TBL-2 catalyst produced by Tianjin University Beiyang Chemical Experimental Equipment Co., Ltd. The equipment is extruded into strips; the strips are dried at 15°C for 10 hours, and then heated in a horse-boiler furnace at a heating rate of 10°C / min from 15°C to 540°C, and roasted at a constant temperature for 5 hours to obtain Ce 2 o 3 Mass fraction 21.43%, Al 2 o 3 The shaped HZSM-5 catalyst of mass ...

Embodiment 2

[0068] Example 2: Preparation of supported metal oxide modified catalyst

[0069] Add 2.0g of magnesium nitrate hexahydrate and 0.2g of citric acid to 20g of deionized water, stir and mix at 10°C for 5 minutes to obtain 22.2g of an impregnating solution with a molar ratio of citric acid penetrant to magnesium element of 0.12:1; 10g of HZSM-5(200) shaped catalyst was added to the impregnation solution, the mass ratio of liquid to solid was 2.22:1, stirred and impregnated at 10°C for 8h; dried at 60°C for 48h, and then placed in a The heating rate is ℃ / min, the temperature is programmed from 10 ℃ to 550 ℃, and the constant temperature is roasted for 4 hours to obtain a modified catalyst with a mass fraction of 3.14% MgO impregnated, which is marked as 3.14MgO / HZSM-5 (200).

[0070] Add 2.0g of magnesium nitrate hexahydrate, 0.5g of lanthanum cerium carbonate, and 0.2g of oxalic acid into 20g of deionized water, and stir and mix at 15°C for 15 minutes to obtain 22.7g of oxalic ac...

Embodiment 3

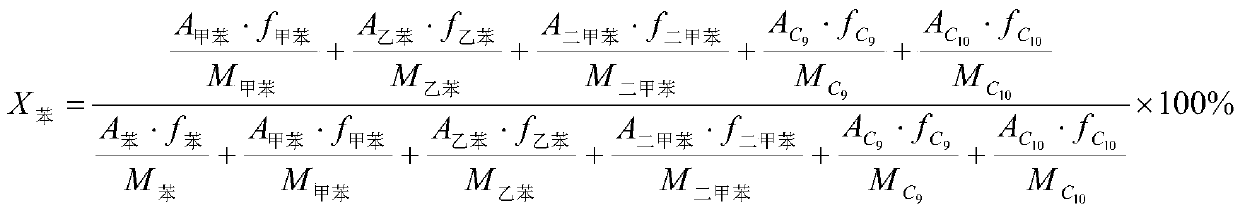

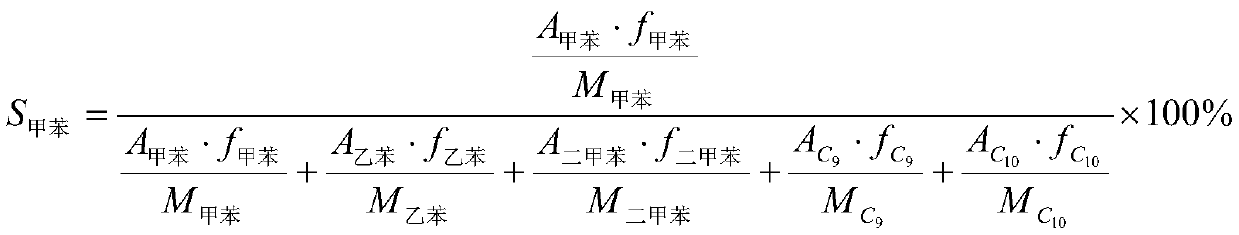

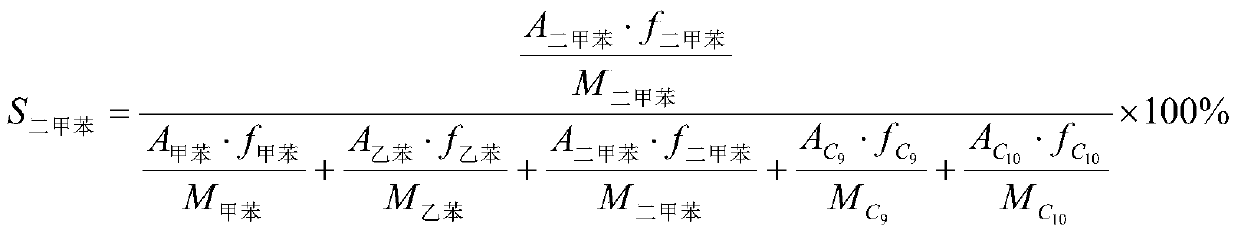

[0080] Embodiment 3: Evaluation of Catalyst Alkylation Catalytic Performance

[0081] Five shaped catalysts and 14 supported metal oxide modified catalysts were used to carry out the alkylation reaction of benzene and methanol under certain conditions, and the catalytic performance of each catalyst was evaluated. Put 4.0g of 20-40 mesh catalyst into the fixed bed reactor, under nitrogen pressure 2.0MPa, nitrogen flow rate 0.2m 3 / h, the temperature of 500 ° C activation conditions, the catalyst activation treatment for 2h. At a temperature of 480°C, a pressure of 0.2MPa, and a mass space velocity of 2.0h -1 , react under the reaction condition of 2:1 of raw material benzene and methanol molar ratio, obtain the benzene conversion rate (X B ), toluene selectivity (S T ), xylene selectivity (S X ), the selectivity of ethylbenzene+C9 aromatics (S E+C9 + ), methanol conversion (X M ), methanol alkylation selectivity (S AM ) The experimental results are listed in Table 1.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com