Nitroglycerin tablet produced continuously

A technology of nitroglycerin and nitroglycerin dichloromethane, which is applied in the direction of nitrate ester preparation, pill delivery, organic chemistry, etc., to achieve the effect of solving a large amount of heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

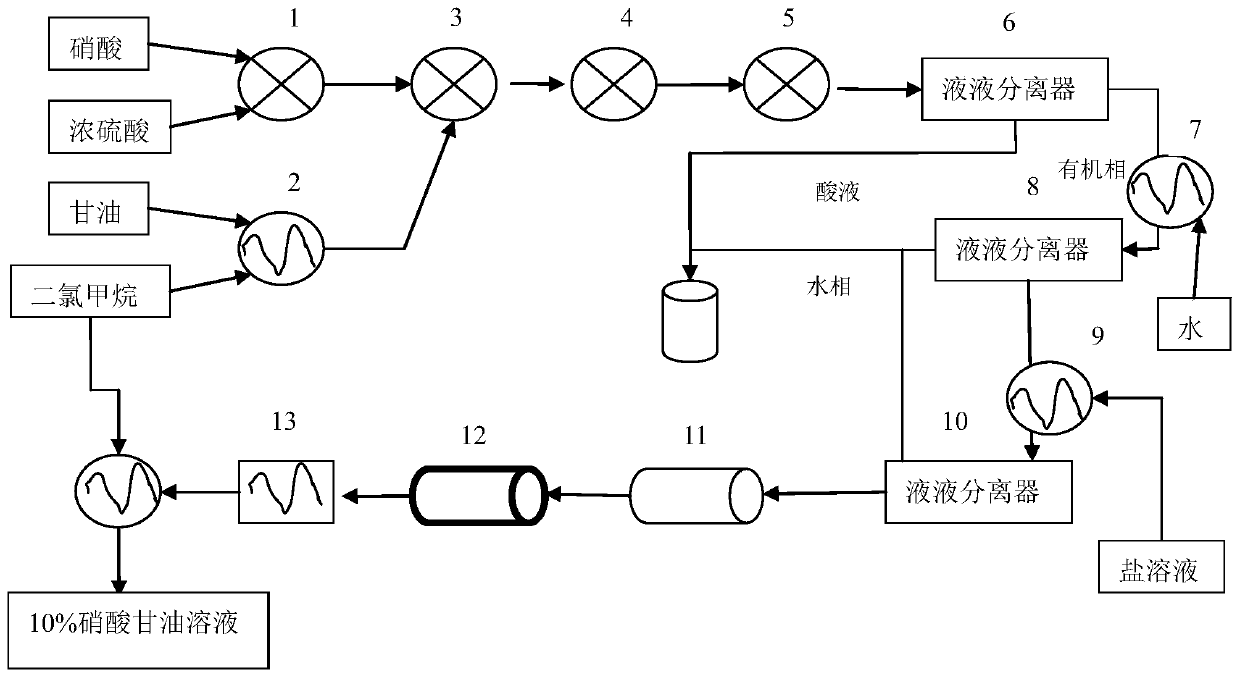

[0071] A tablet of nitroglycerin is characterized in that: concentrated sulfuric acid and fuming nitric acid are mixed by microreactor chip (1); glycerin and dichloromethane are input into mixer (2), and microreactor chip (1 ) mixed acid solution and the solution of the mixer (2) are input in the microreactor chip (3), (4), (5), the reaction solution is retained in the microreactor, and the reaction solution is from the microreactor chip (5 ) into the Zaiput liquid-liquid separator (6), the acid liquid is input into the waste liquid processor, and after the organic phase is mixed with water input into the mixer (7), it is input into the Zaiput liquid-liquid separator (8), and the water phase is input into In the waste liquid processor, the organic phase and saturated salt solution are input to the Zaiput liquid-liquid separator (9), the water phase is input to the waste liquid processor, and the organic phase passes through the molecular sieve desiccant column (10), through the...

Embodiment 2

[0073] A tablet of nitroglycerin, characterized in that: concentrated sulfuric acid and fuming nitric acid are mixed at a speed ratio of 1:1 through a microreactor chip (1); glycerin and dichloromethane are input into the mixing chamber at a speed ratio of 0.2:2 device (2), the mixed acid solution of the microreactor chip (1) and the solution of the mixer (2) are input to the microreactor chip (3), (4), (5) at a speed ratio of 2:2.75, The retention time of the reaction solution in the microreactor is 10min to 30min, the reaction solution is input from the microreactor (5) to the Zaiput liquid-liquid separator (6), the acid solution is input to the waste liquid processor, and the organic phase is mixed with water to the input After the device (7) is mixed, it is input to the Zaiput liquid-liquid separator (8), the water phase is input to the waste liquid processor, the organic phase and saturated salt solution are input to the Zaiput liquid-liquid separator (9), and the water ph...

Embodiment 3

[0081] Green Tablets of Nitroglycerin (1)

[0082] The weight ratio of each component

[0083]

[0084]

[0085] Prepare as follows:

[0086] (1) Dry mix the green granules of nitroglycerin with microcrystalline cellulose passed through a 200-mesh sieve for 1 hour, stir well, and mix for 3 hours to make soft materials; make wet granules; dry at 40°C for 4 hours ; Pass the dry granules through an 80-mesh sieve; granulate to obtain drug-containing granules;

[0087] (2) Mix the drug-containing granules, crospovidone and magnesium stearate evenly, and press into tablets.

[0088] Nitroglycerin Tablets (2)

[0089] The weight ratio of each component

[0090]

[0091] Follow these steps:

[0092] (1) Dry mix the green granules of nitroglycerin with microcrystalline cellulose passed through a 200-mesh sieve for 1 hour, stir well, and mix for 3 hours to make soft materials; make wet granules; dry at 40°C for 4 hours ; Pass the dry granules through an 80-mesh sieve; gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com