A water plant dosing device

A technology of dosing device and waterworks, which is applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. It can solve the problem of flocculation entering the pipeline, excessive flocculation, and affecting the device Service life and other issues, to achieve the effect of saving manpower and time, reducing cost, and ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

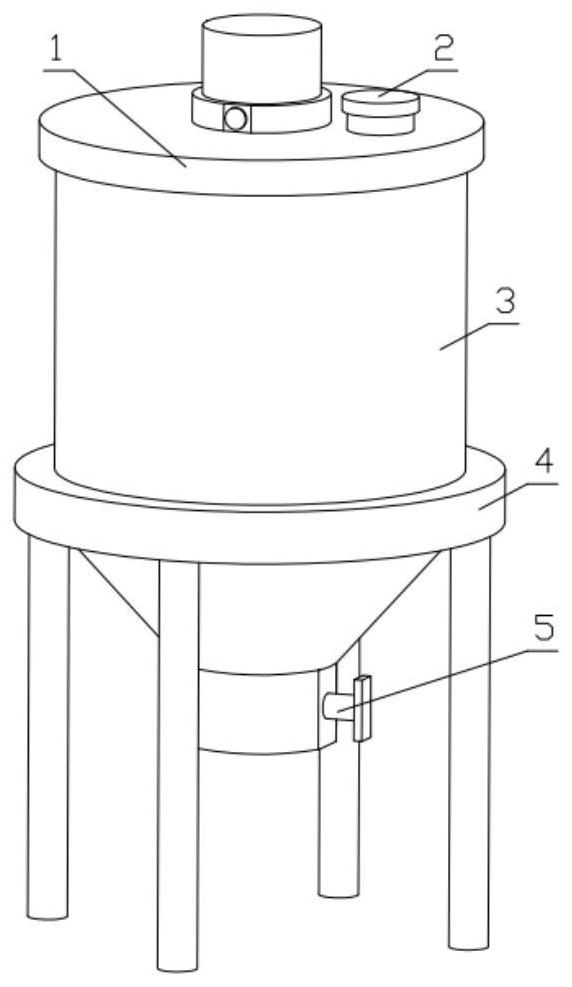

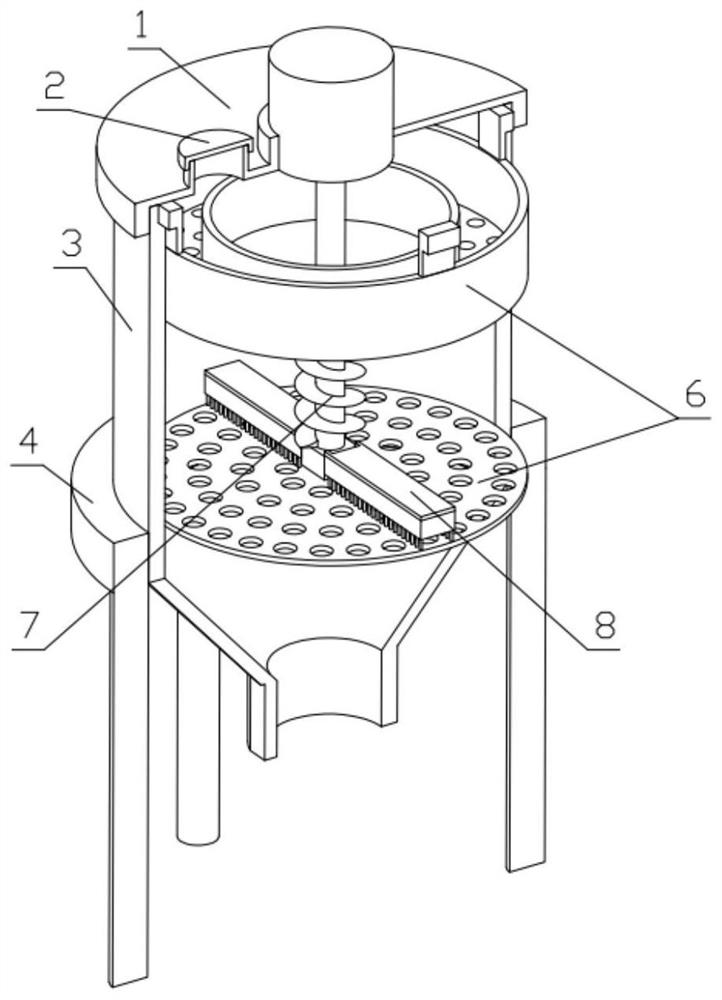

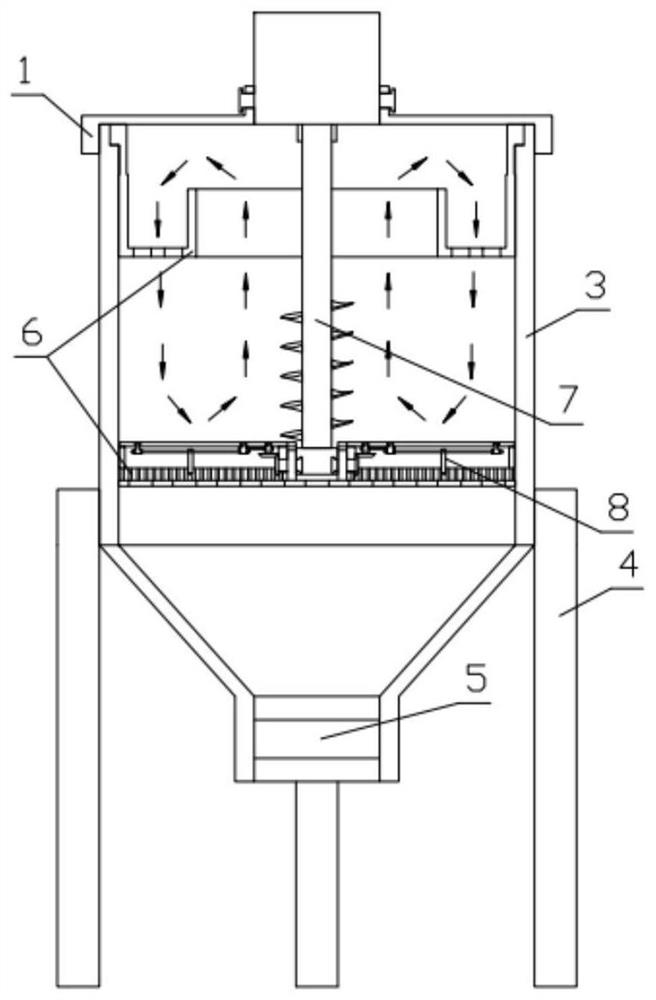

[0029] Combine below Figure 1-11 Illustrate this embodiment, a kind of waterworks dosing device, comprises top cover 1, side cover 2, container box 3, box body support 4 and valve 5, and container box 3 is fixedly installed on the box body support 4, and the container box 3 There is a valve 5 at the outlet of the lower end, the top cover 1 is threaded with the container box 3, the side cover 2 is threaded with the top cover 1, the filter assembly 6 is installed in the container box 3, and the water flow adjustment assembly 7 is fixed by fastening screws Installed on the through hole provided on the top cover 1, there are two stirring and cleaning mechanisms 8, which are respectively installed at the two ends of the water flow adjustment assembly 7, and the stirring and cleaning mechanisms 8 are in contact with the filter assembly 6.

specific Embodiment approach 2

[0030] Combine below Figure 1-11 Describe this embodiment, this embodiment will further explain the first embodiment, the filter assembly 6 includes a filter disc 6-1, an annular filter tank 6-2, an L-shaped hook 6-3, and the filter disc 6-1 is fixed Installed in the container box 3, the number of L-shaped hooks 6-3 is four, evenly fixed and installed on the annular filter tank 6-2, and the L-shaped hooks 6-3 are slidably installed in the groove provided on the container box 3 superior.

specific Embodiment approach 3

[0031] Combine below Figure 1-11 Describe this embodiment, this embodiment will further explain the first embodiment, the water flow adjustment assembly 7 includes a driving motor 7-1, a connecting rod 7-2, an upwardly threaded fan blade 7-3, and a mounting square piece 7-4, One end of the connecting rod 7-2 is fixedly mounted on the output end of the drive motor 7-1, the other end of the connecting rod 7-2 is fixedly installed with a square piece 7-4, and the connecting rod 7-2 is provided with an upward threaded fan blade 7 -3, drive the motor 7-1 to be fixed and installed on the through hole provided on the top cover 1 through fastening screws, and the upwardly threaded fan blade 7-3 changes the flow direction of the liquid medicine, and cooperates with the annular filter tank 6-2 to effectively flocculate Collect the flocs in a centralized manner, and the flocs are driven by the liquid flow to form a cycle to achieve the purpose of continuous cleaning of the flocs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com