A spraying drone automatic injection equipment

An unmanned aerial vehicle, automatic technology, applied in packaging, liquid distribution, conveying or transfer devices, transportation and packaging, etc., can solve the problems of cumbersome operation, low work efficiency, and unmanned aerial vehicle dumping, etc., to achieve simple operation and avoid dumping. , the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

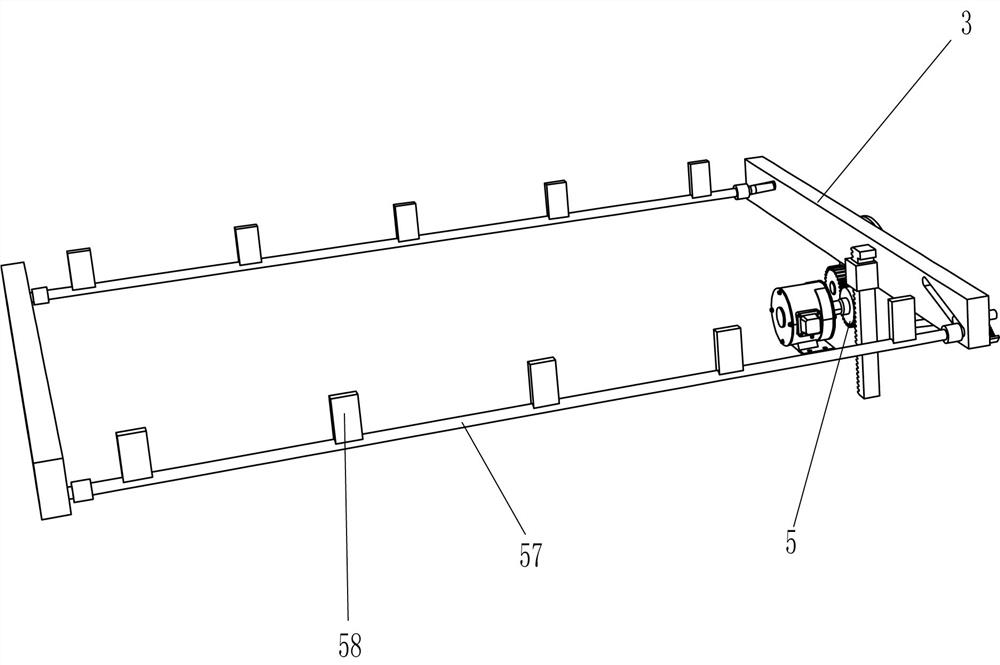

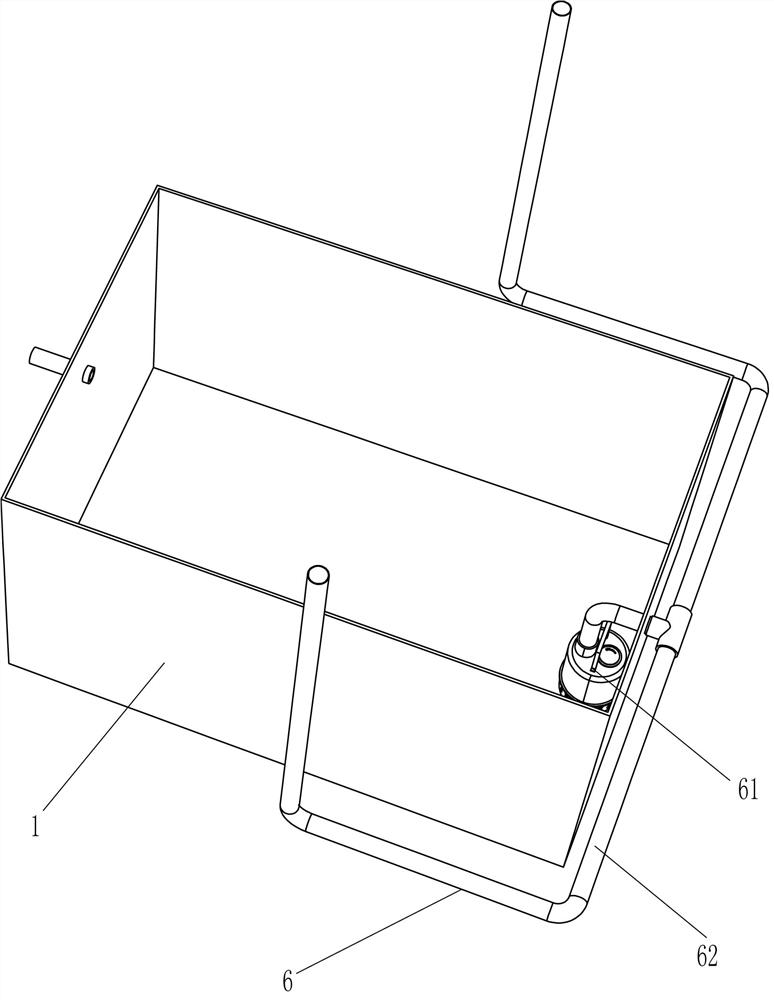

[0027] A spraying drone automatic injection equipment, such as Figure 1-7 As shown, it includes a sinking water tank 1, a fixing plate 2, a cover plate 21, a guide plate 3 and a side plate 4, the top of the sinking water tank 1 is connected with a fixing plate 2, and the middle part of the fixing plate 2 is provided with a detachable cover plate 21, The bottoms of the left and right sides of the fixed plate 2 are connected with guide plates 3, the front and rear sides of the fixed plate 2 are connected with side plates 4, and a positioning mechanism 5 and a dosing mechanism 6 are also included. There is a positioning mechanism 5, and a dosing mechanism 6 is arranged between the sinking water tank 1 and the side plate 4.

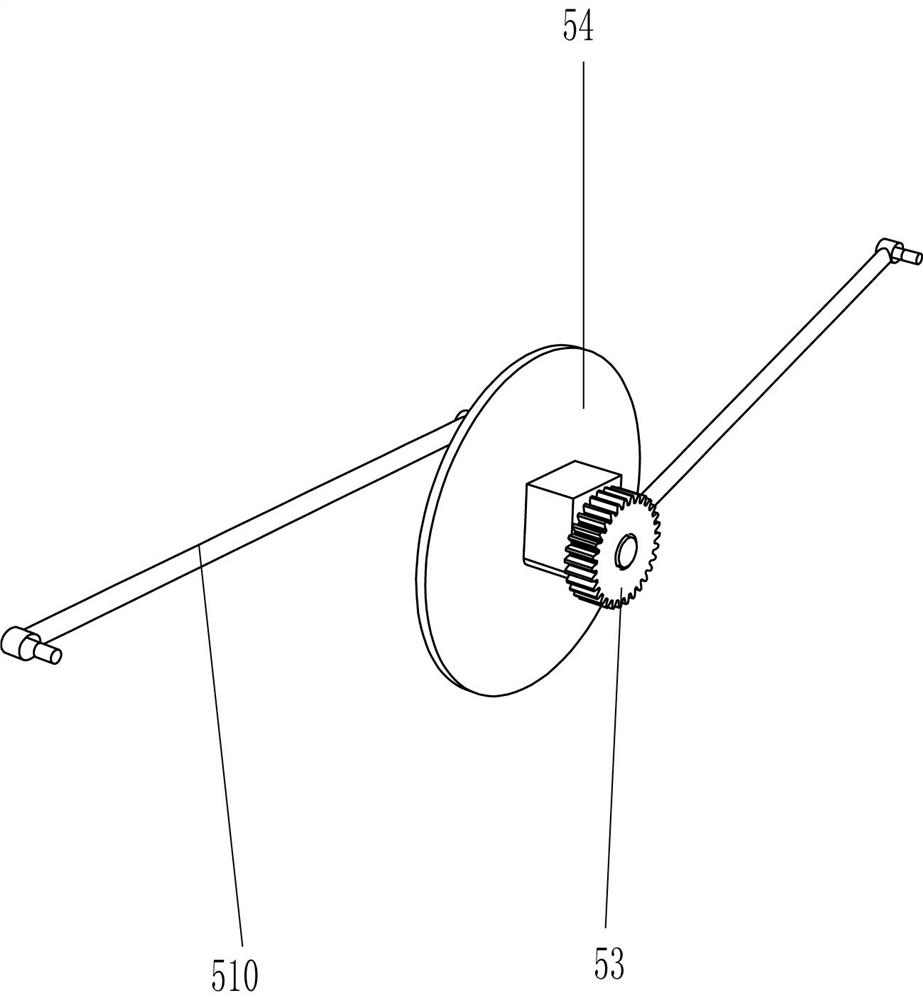

[0028] The positioning mechanism 5 includes a driving motor 51, a sector gear 52, a first cylindrical gear 53, a rotating disk 54, a guide block 56, a connecting rod 57, a positioning plate 58, an extension spring 59 and a connecting rod 510, and the sinking...

Embodiment 2

[0032] On the basis of Example 1, such as figure 1 and 6 As shown, the rotating assembly 7 is also included, and the rotating assembly 7 includes a fixed pipe 71, a vertical rack 72, a return spring 73, a second cylindrical gear 74, a pulley 75, a slide rail 76, a slider 77 and a pull wire 78, two The inner bottom of the side plate 4 is connected with a fixed pipe 71, and a vertical rack 72 is slidably connected in the fixed pipe 71, and a return spring 73 is connected between the vertical rack 72 and the fixed pipe 71, and the transmission of the swing liquid outlet pipe 63 A second cylindrical gear 74 is connected to the shaft, and the second cylindrical gear 74 meshes with the vertical rack 72. Both sides of the bottom of the fixed plate 2 are rotatably connected with pulleys 75, and both sides of the bottom of the fixed plate 2 are connected with slide rails. 76, slide rail 76 is slidingly connected with slide block 77, and slide block 77 can contact with connecting rod 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com