Rotary granulator

A technology of rotary granulator and rotary chassis, which is applied in the direction of raw material extrusion and granulation, which can solve the problems of easy water ingress and rust, inability to process small particles, metal powder pollution, etc. Powder pollution, good extrusion effect, simple cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

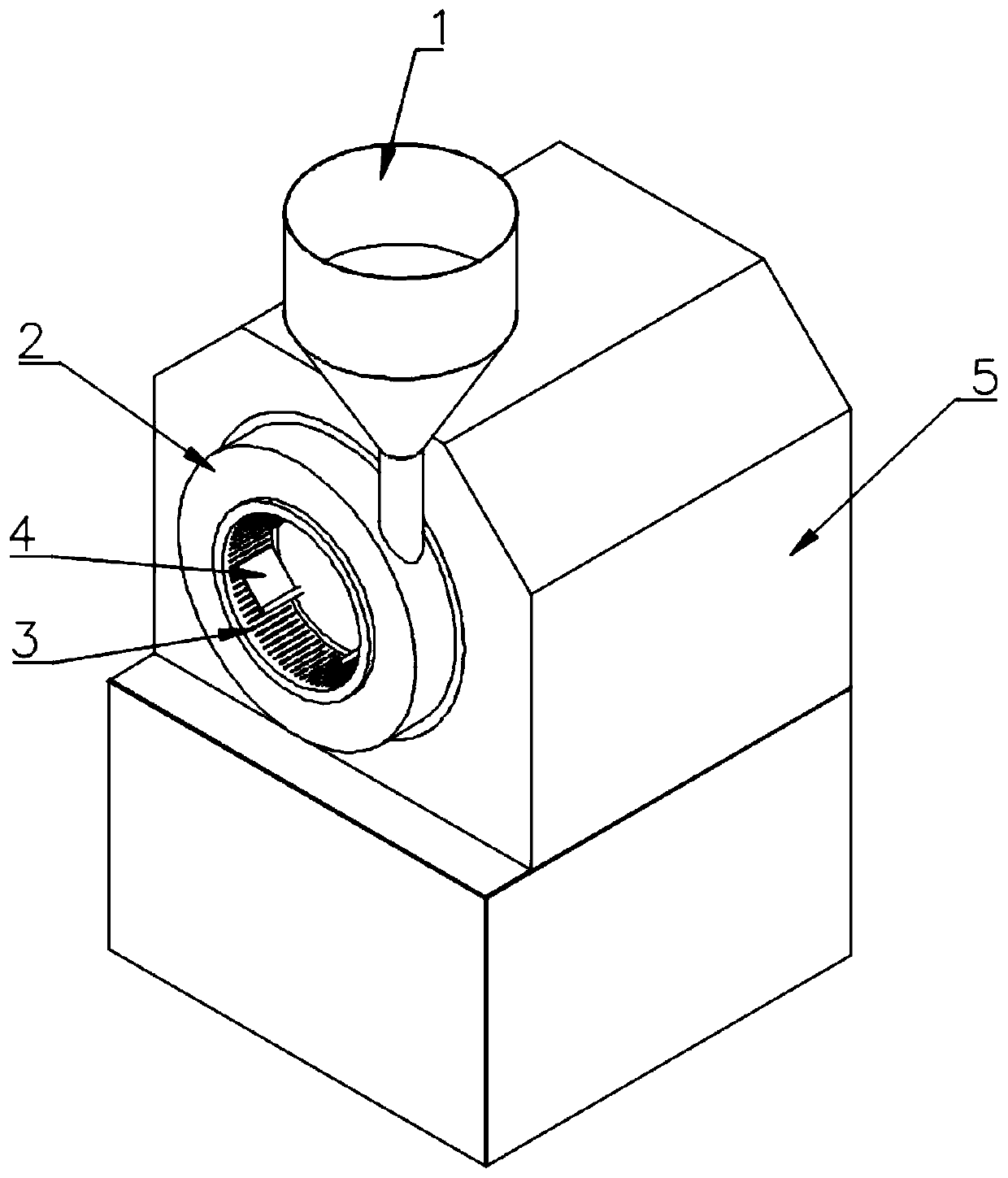

[0031] Such as figure 1 As shown, a rotary granulator includes frame 5.

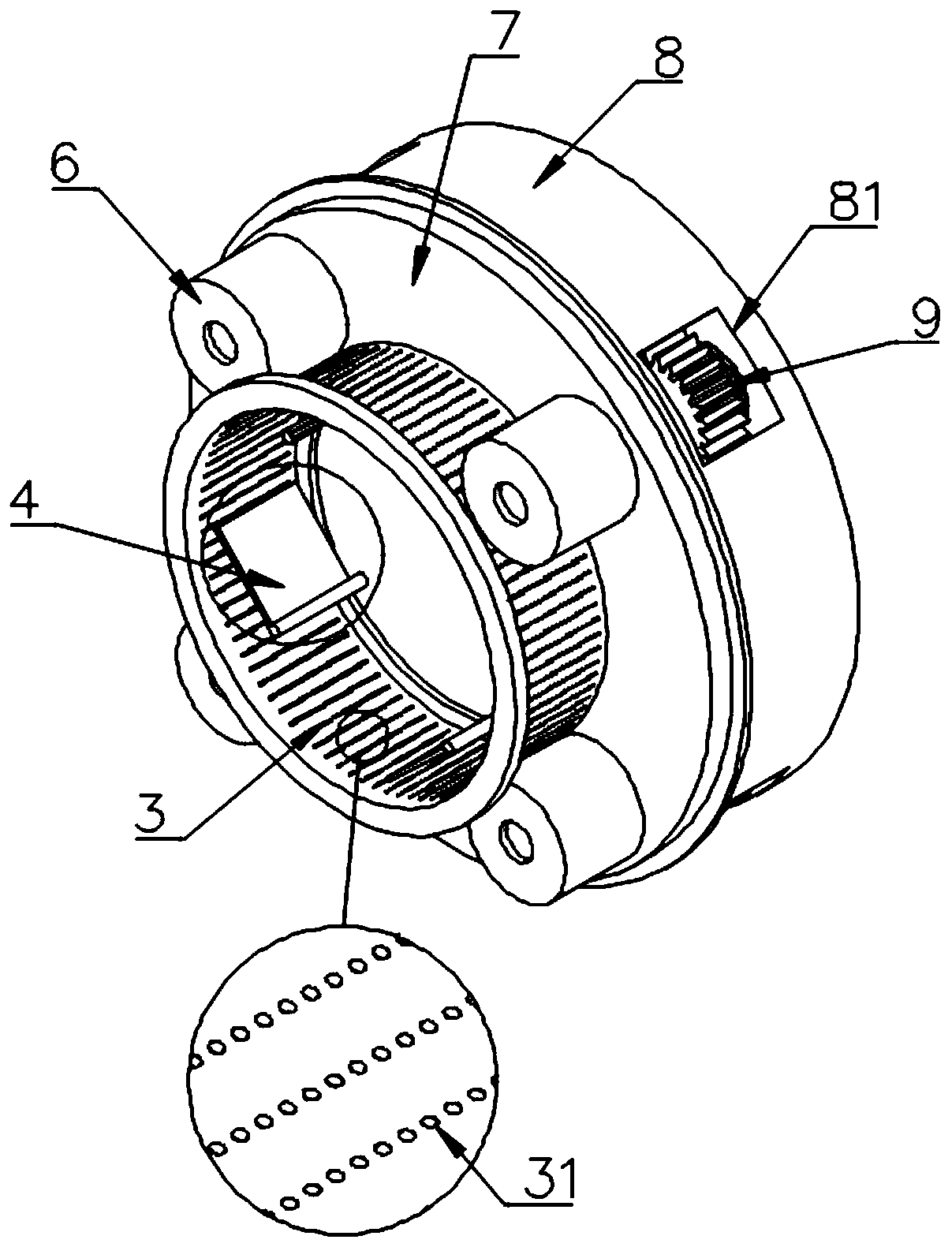

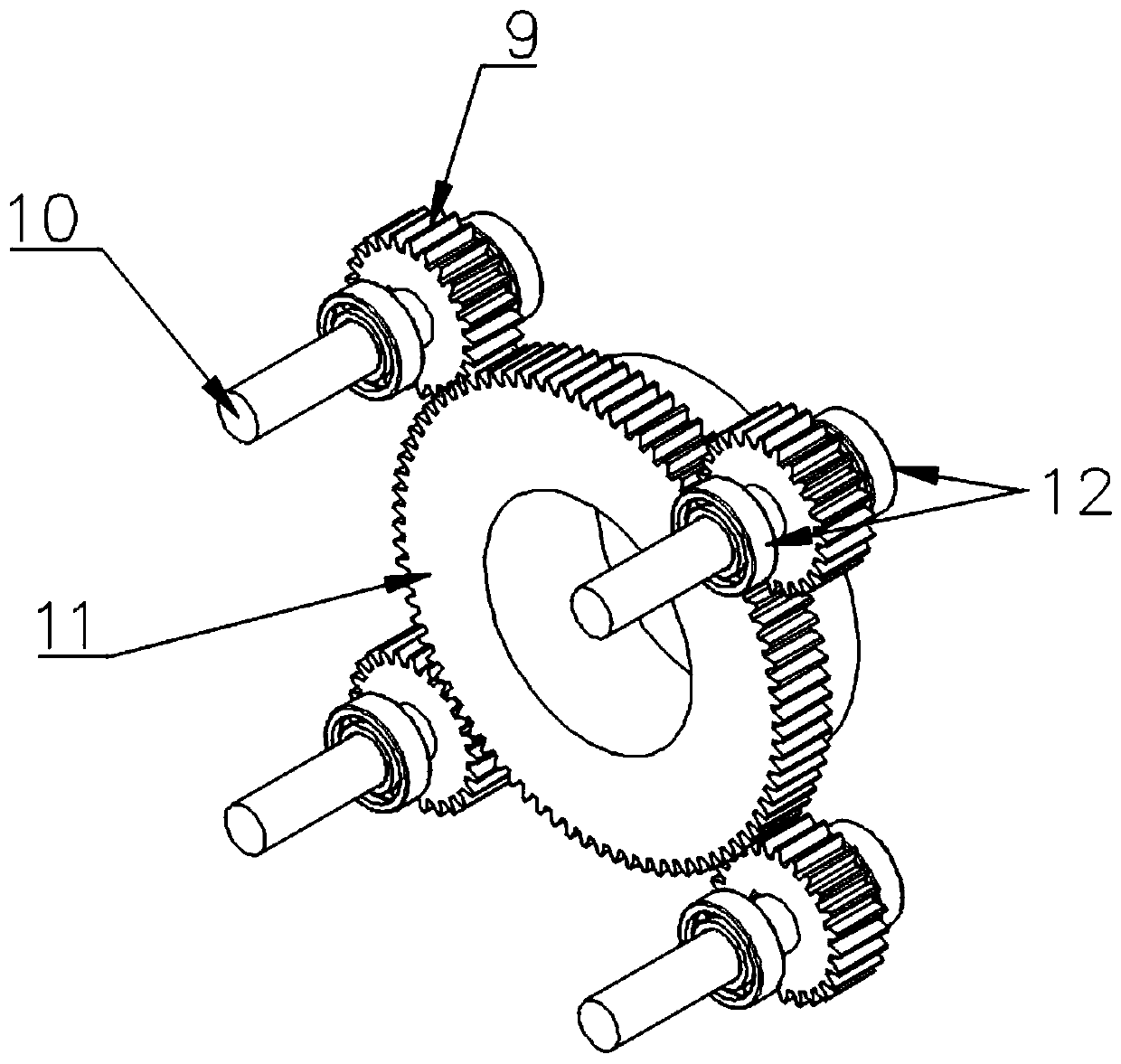

[0032] Such as figure 2 As shown, also includes planetary carrier 8, such as image 3 As shown, the planetary carrier 8 has a built-in sun gear 11, and further, the sun gear 11 is fixed on the casing (not shown), the casing is fixed inside the frame 5, and the planetary carrier 8 is fixedly connected with a driving device (not shown). ), the driving device (not shown) drives the planet carrier 8 to rotate. The drive device can use a reducer. Further, the reducer drives the planet carrier 8 to rotate.

[0033] Such as image 3 As shown, the sun gear 11 is externally meshed with several planetary gears 9, and the planetary gears 9 are provided with planetary shafts 10; further, as image 3 As shown, each planetary shaft 10 is provided with two bearings 12 , the planetary gear 9 is placed between the two bearings 12 , and the planetary shaft 10 is passed through the planetary carrier 8 and is rotatab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com