Biological fertilizer drying system

A drying system and bio-fertilizer technology, applied in the direction of manure drying, drying solid materials, heating to dry solid materials, etc., can solve the problems of high moisture content of bio-fertilizer, heat removal, waste of resources, etc., to achieve uniform drying and improve Dehydration efficiency, effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

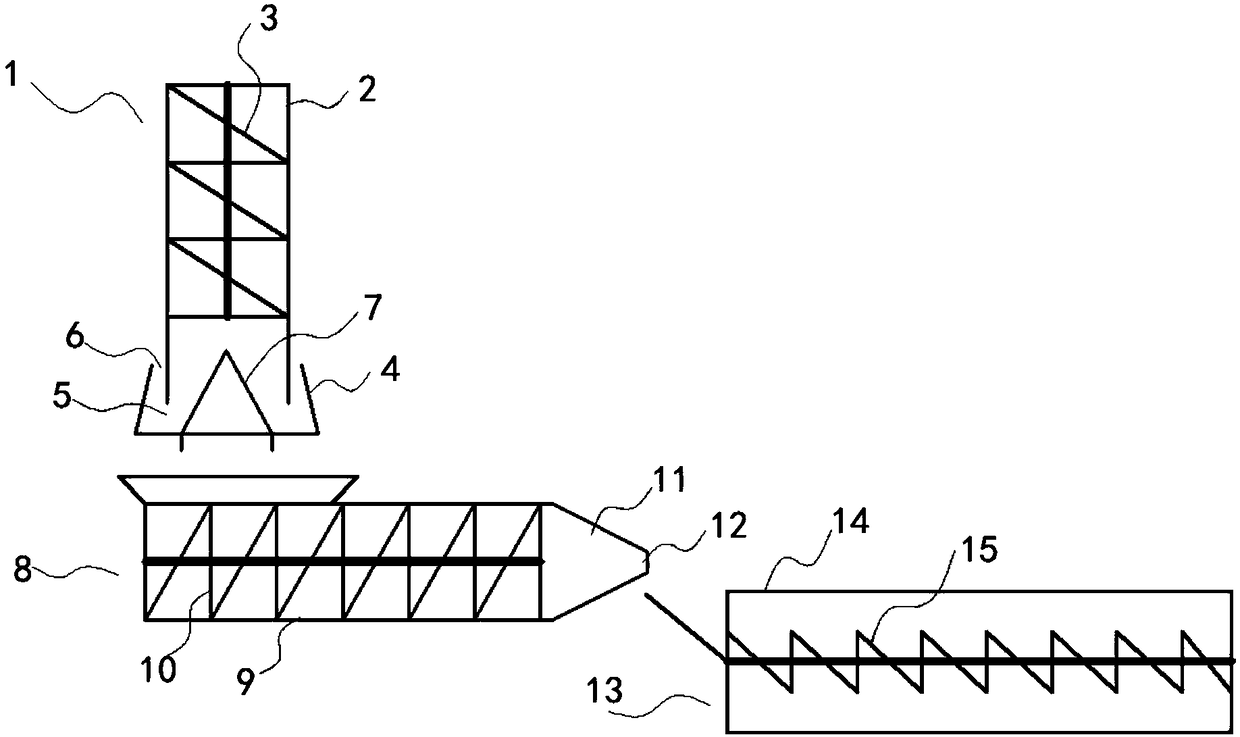

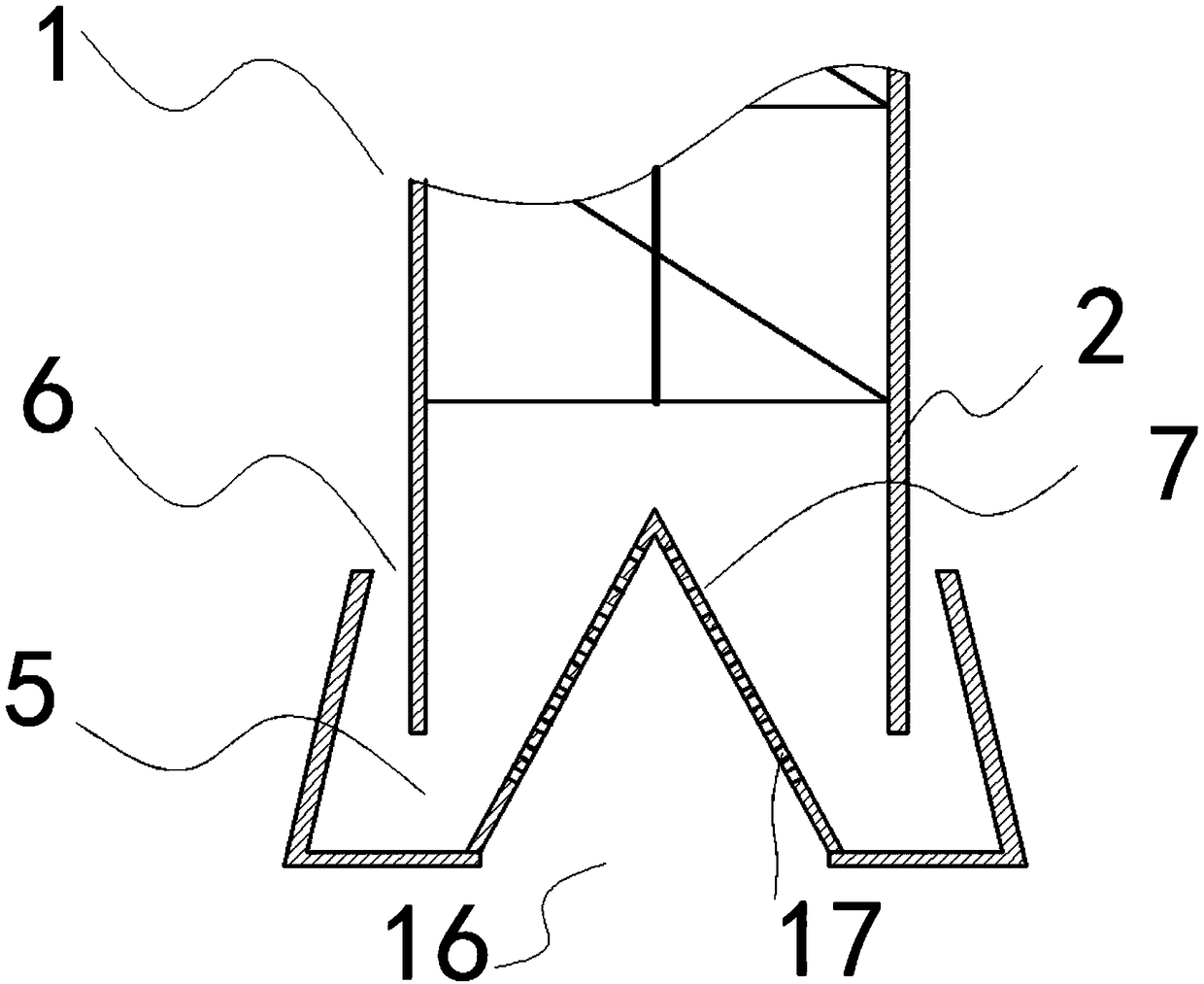

[0031] Such as figure 1 and 2 Shown, a kind of biological fertilizer drying system, wherein, comprises:

[0032]The first material extruding device 1 includes a vertically arranged first cylinder 2, a first screw feeding mechanism 3 arranged inside the first cylinder, a cover arranged on the lower part of the first cylinder and connected with the first cylinder. A cylindrical relatively fixed material tray 4, the upper opening of the first cylinder 2 is a material inlet, and materials are put into the material inlet, and the first screw feeding mechanism 3 pushes the material down, and the material tray 4 has A horizontal circular bowl bottom and a circular bowl mouth with decreasing radius. The first cylinder 2 is inserted into the tray from the bowl mouth and extends down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com