Convenient photovoltaic module mounting bracket and processing and mounting method

A technology of photovoltaic modules and mounting brackets, which is applied to the support structure of photovoltaic modules, photovoltaic power generation, photovoltaic modules, etc., and can solve the problems of low power generation efficiency of photovoltaic modules on the back side, many installation procedures of photovoltaic support systems, troublesome disassembly of photovoltaic modules, etc. , to achieve the effect of reducing the complex installation process, reducing the load-bearing requirements, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

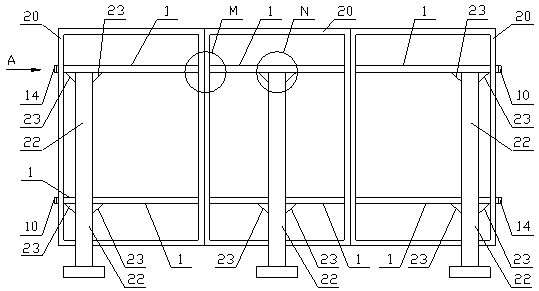

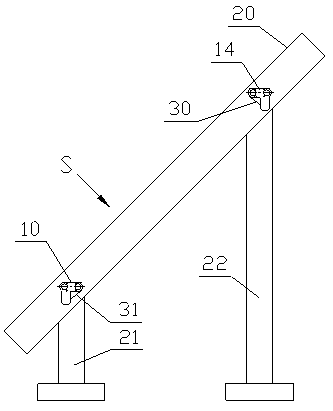

[0065] like figure 1 , 2 As shown, the two groups of profile bodies 1 pass through the first mounting groove 30 and the second mounting groove 31 on the frame 20 of the photovoltaic module, and then are fixedly connected to the first column 21 and the second column 22 through the screw assembly 24 and the connecting plate 23 respectively; The first installation groove 30 and the second installation groove 31 are preferably symmetrical structures, which can realize self-locking after the installation of two groups of profile main bodies 1; 1. The frame wall of the second installation groove 31 is matched and fastened.

[0066] like image 3 As shown, the end surface of the profile main body 1 has a first through hole 2, an end cover screw hole 3, a screw groove 4, a main rib 5, a second through hole 6, and a card groove 7. The first through hole 2 and the second through hole 6 are symmetrical The structure can reduce the weight of the whole body and at the same time can inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com