Motor counter electromotive force sampling module and sampling method

A sampling module, back EMF technology, applied in the direction of motor, excitation or armature current control, electric vehicle, etc., can solve the problem of affecting the control performance of the motor, the voltage of the motor terminal cannot be restored, and the duty cycle cannot be high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

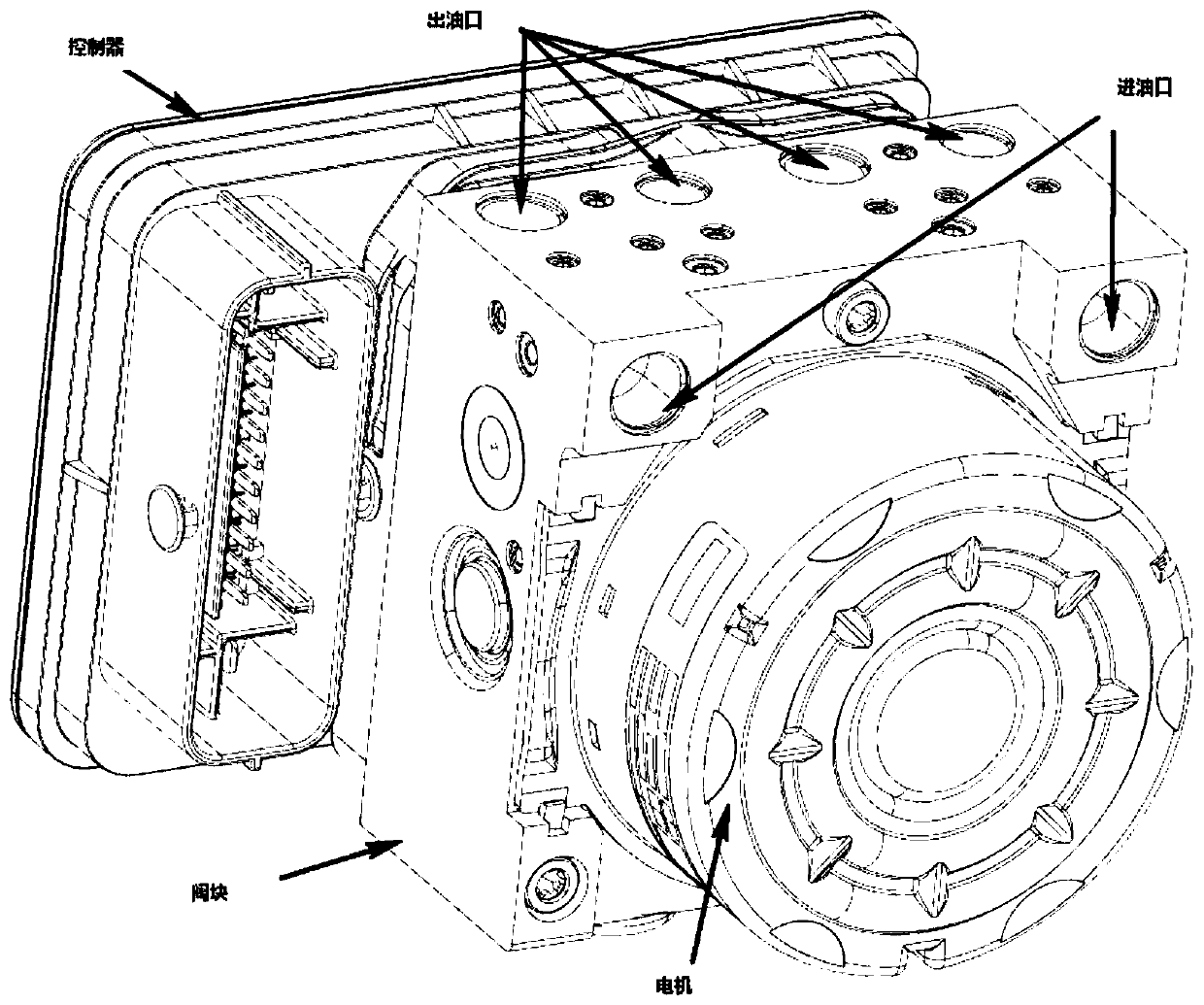

[0044] refer to image 3 combine Figure 4 As shown, the first embodiment of the motor back EMF sampling module provided by the present invention includes:

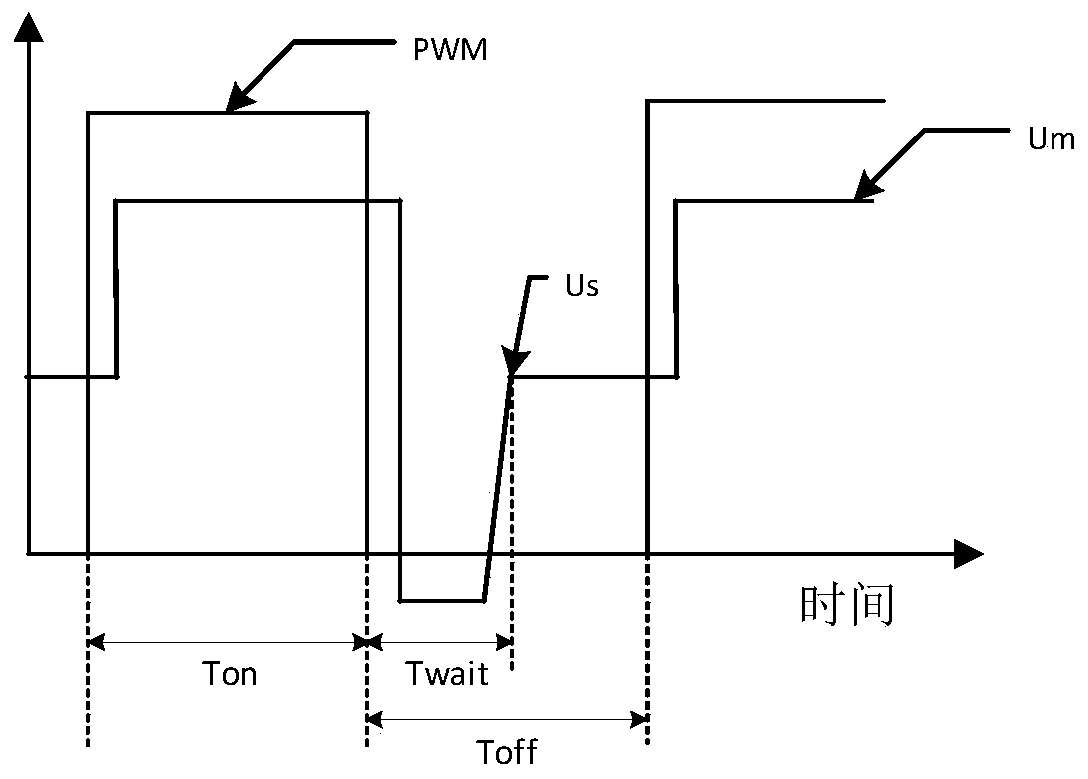

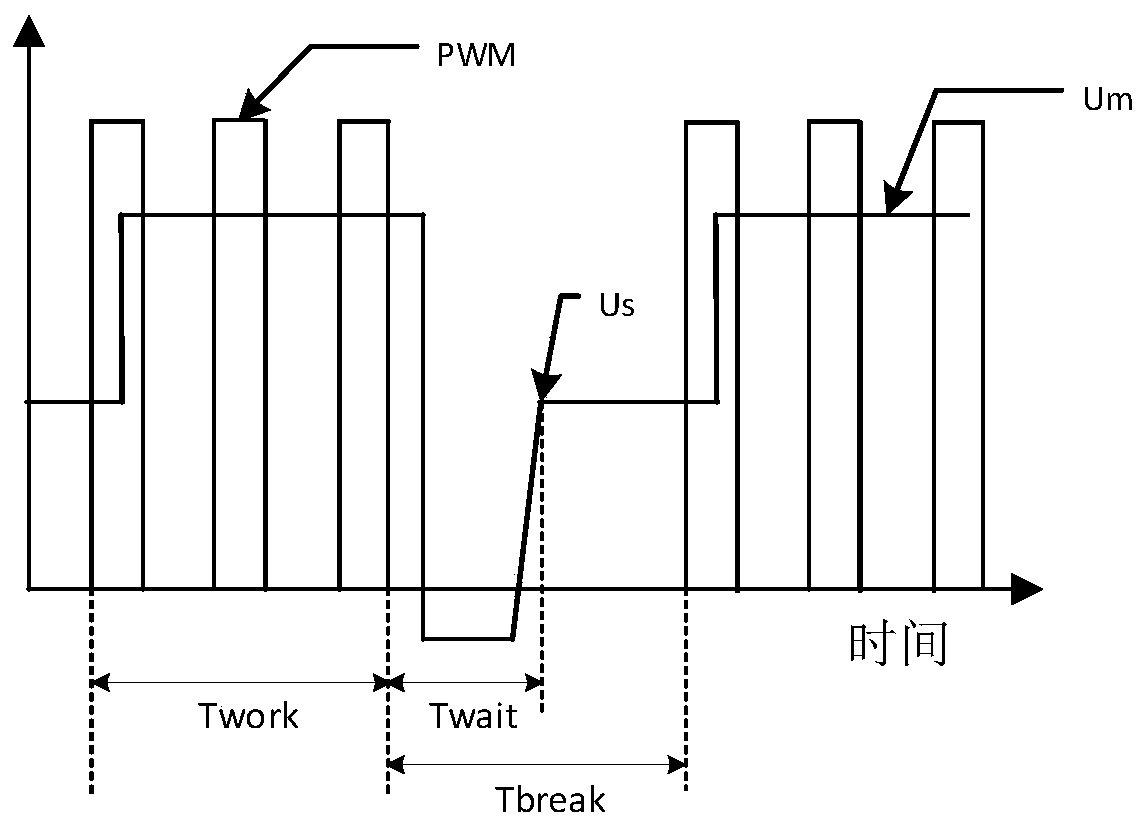

[0045] The motor drive unit is suitable for outputting PWM to the drive circuit according to the control duty ratio, and the drive circuit outputs the preset waveform motor drive voltage, which is suitable for receiving the back EMF sampling interrupt signal to stop outputting PWM, and the preset waveform motor drive voltage drop to zero, and last for Tbreak time, after the Tbreak time is over, output PWM to restore the preset waveform motor drive voltage;

[0046] Motor control unit, which is suitable for calculating the required control duty cycle according to the target speed and the actual speed calculated by the back EMF, and sending the duty cycle to the motor drive unit, which is suitable for generating back EMF sampling every interval (Twork+Tbreak) The interrupt signal is sent to the motor drive unit and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com