Hybrid power driving system with bidirectional power interruption mechanism

A hybrid power and drive system technology, applied in the direction of hybrid power vehicles, motor vehicles, transportation and packaging, etc., to achieve the effect of reducing NVH problems, reducing energy consumption of the whole vehicle, and optimizing the power input structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

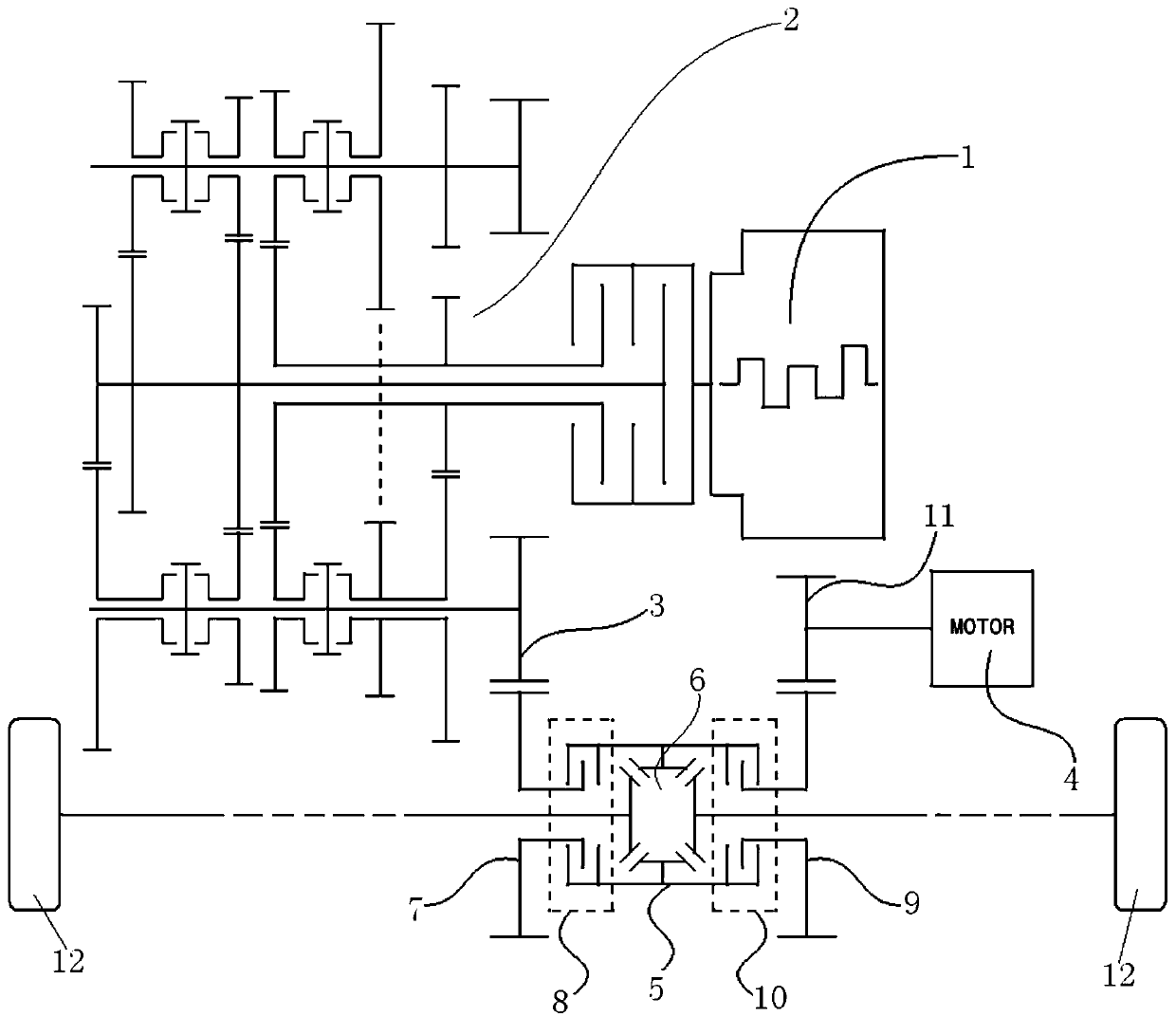

[0024] Such as figure 1 As shown, a hybrid drive system with a two-way power interruption mechanism includes an engine 1, a transmission 2 and a drive motor 4, the engine 1 is connected to the transmission 2, and is connected to the transmission 2 through a power output gear 3 is connected to a differential, and the other end of the differential is connected to the drive motor 4; a first power disconnection and coupling structure 8 is provided between the power output gear 3 and the differential, so A second power disconnection and connection structure 10 is provided between the drive motor 4 and the differential.

[0025] The hybrid drive system operates by setting the first power disconnection and coupling structure 8 on the power transmission path of the engine 1, and setting the second power disconnection and coupling structure 8 on the power transmission path of the drive motor 4. Combined with the structure 10, a two-way power disconnectable structure is formed, and the...

Embodiment 2

[0035] This embodiment provides the hybrid mode of the hybrid drive system with the bidirectional power interruption mechanism described in the first embodiment.

[0036] In the hybrid mode, the first power disconnection and coupling structure 8 and the second power disconnection and coupling structure 10 are both in a combined state; the power transmission path of the engine 1 passes through the transmission 2 in sequence , the power output gear 3, the first power disconnection and coupling structure 8 and the differential reach the wheels 12; at the same time, the power transmission of the drive motor 4 passes through the motor reduction gear 11, the The second power disconnection and coupling structure 10 , the differential gear reaches the wheels 12 again.

[0037] At this moment, the power of the engine 1 and the drive motor 4 is jointly transmitted and acted on the wheels 12 , so that the hybrid running of the vehicle can be realized with abundant power and fuel saving. ...

Embodiment 3

[0039] This embodiment provides the pure electric mode of the hybrid drive system with the bidirectional power interruption mechanism described in the first embodiment.

[0040] In the pure electric mode, the engine 1 stops working, the first power disconnection and combination structure 8 is in a disconnected state, and the power of the drive motor 4 passes through the second power disconnection and combination state. The combination structure 10 is transmitted to the differential and then to the wheels, so as to realize pure electric driving of the vehicle.

[0041] At this time, the power of the engine has been interrupted in both directions. Even if the drive motor 4 is still running, it can not drive the internal gears such as the engine 1, the transmission 2, and the power output gear 3. The noise caused by the idling of the large gear; the output power of the drive motor 4 is basically transmitted to the wheels 12, reducing power loss and improving the efficiency of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com