Automatic assembling and locking production line for miniature circuit breaker

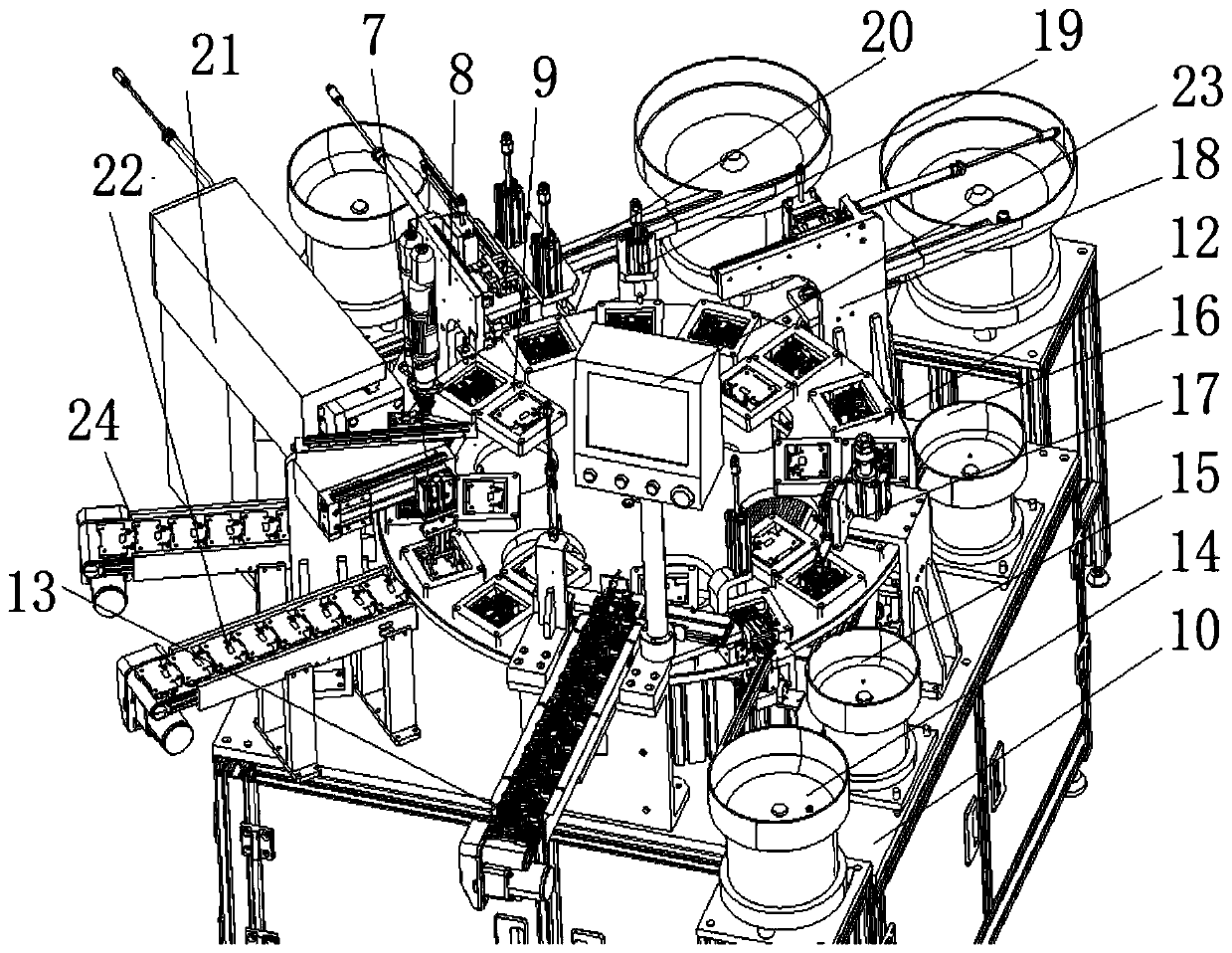

A miniature circuit breaker and automatic assembly technology, which is applied in the manufacture of circuits, emergency protection devices, emergency protection devices, etc., can solve the problems of insufficient locking and assembly, missing installation and inspection, and low assembly efficiency, achieving compact layout, The effect of long service life and high working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

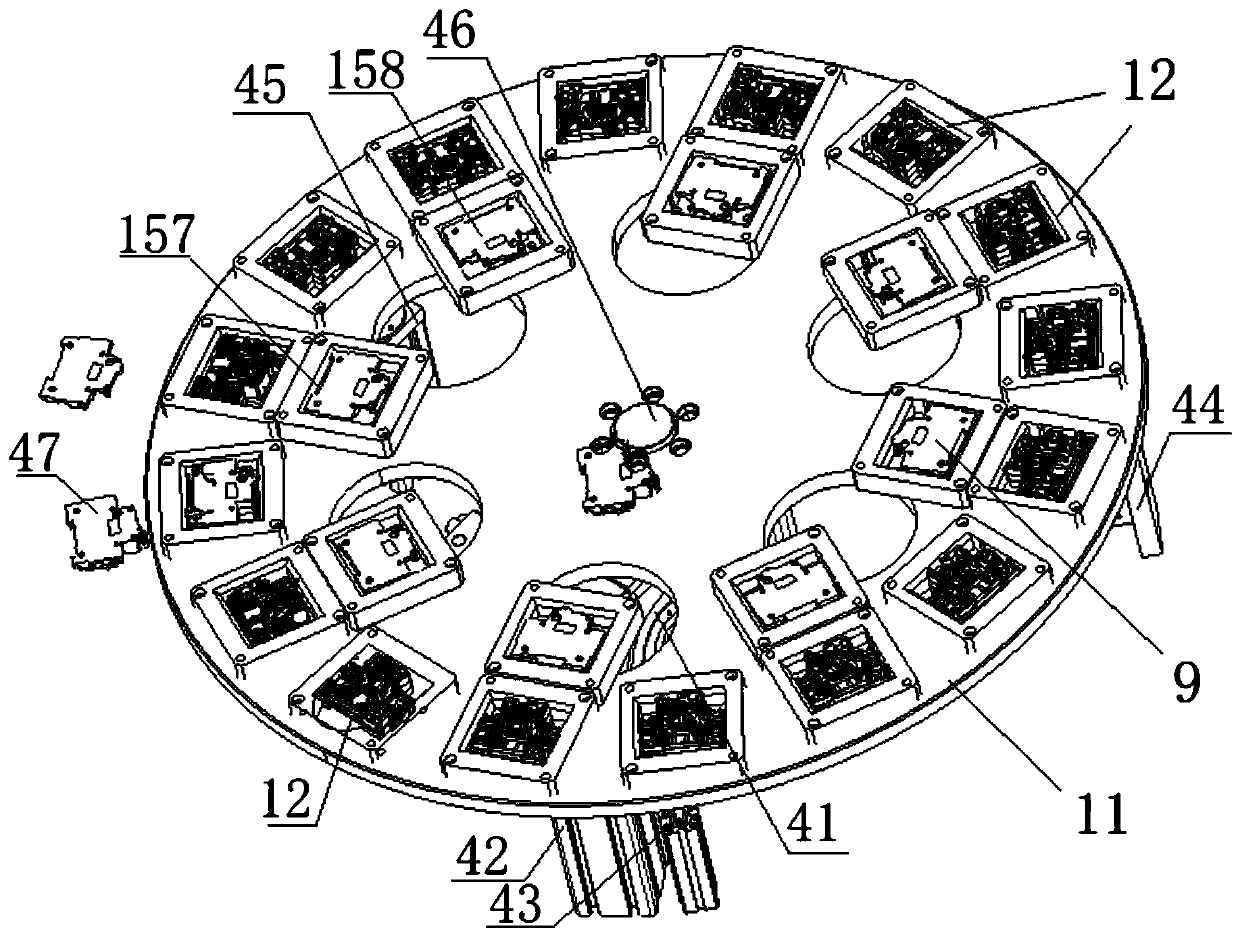

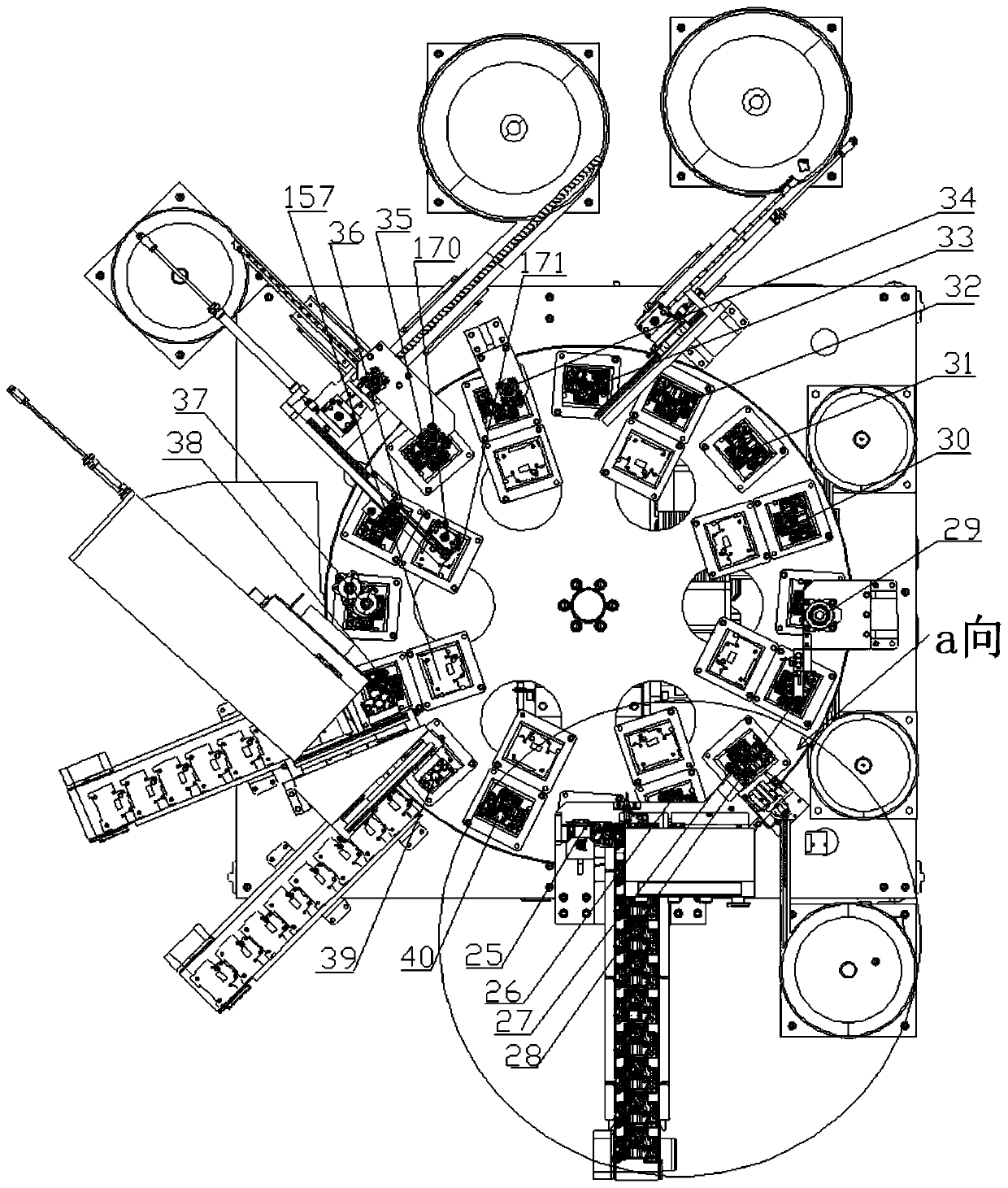

[0044] The upper, lower, left, and right positions in the following text descriptions are subject to the figures shown in the corresponding drawings, and the actual installation positions can be deduced by analogy.

[0045] refer to Figure 11 , is the object product (miniature circuit breaker 1) that needs to be automatically assembled by the system of the present invention. It is necessary to continue to assemble the upper cover 3, the hex nut 5, the pan head screw 6, and the contact support plate on the base 4 of the pre-installed semi-finished circuit breaker 2 150 , the arc guide plate 151 , the arc extinguishing cover 152 , and the adjusting nut 153 , and finally obtain a finished product sample of the miniature circuit breaker 1 with firm installation.

[0046] The structure of the finished product sample of the miniature circuit breaker 1 is that the semi-finished circuit breaker 2 with pre-cured basic components is set in the base 4, the upper cover 3 is fastened on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com