Fully automatic assembling machine for spring fasteners

一种全自动、弹簧扣的技术,应用在组装机、接触件的组装/拆卸、振动输送机等方向,能够解决组装不方便、人工组装费时费力、增加人工成本等问题,达到操作方便、方便组装、生产效率高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

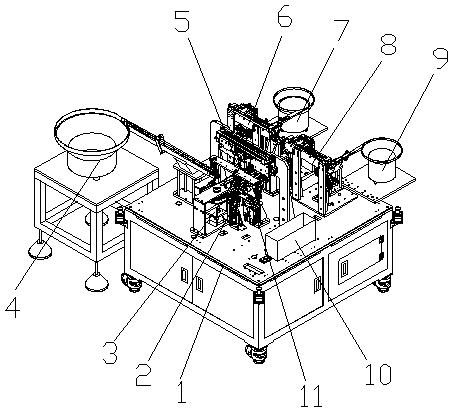

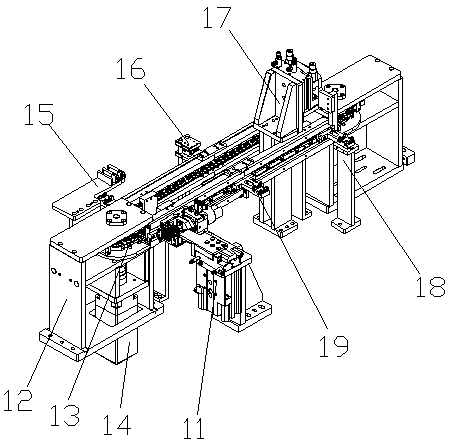

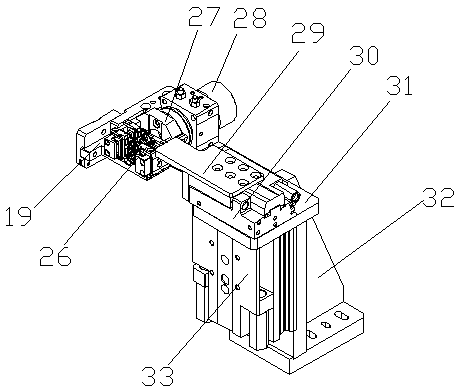

[0039] Such as Figure 1-Figure 13 As shown, the structure of the present invention is: a fully automatic assembly machine for spring fasteners, which includes a frame 1 and a power distribution control box. 3 around the rubber shell feeding device, the fastener feeding device and the spring feeding device, the rubber shell feeding device includes the rubber shell feeding vibrating plate 4 arranged on the left front side of the circulation conveying device 3, and the rubber shell feeding device The vibrating plate 4 is connected with the rubber shell distribution block 15 through the rubber shell conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com