Spring transporting machine of spray pump spring and small bowl assembling machine

The technology of a spring mechanism and a small bowl set is applied in the field of design and manufacture of automatic assembly machines for spray pumps, and achieves the effects of wide application range, fast and accurate positioning, and simple and practical structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

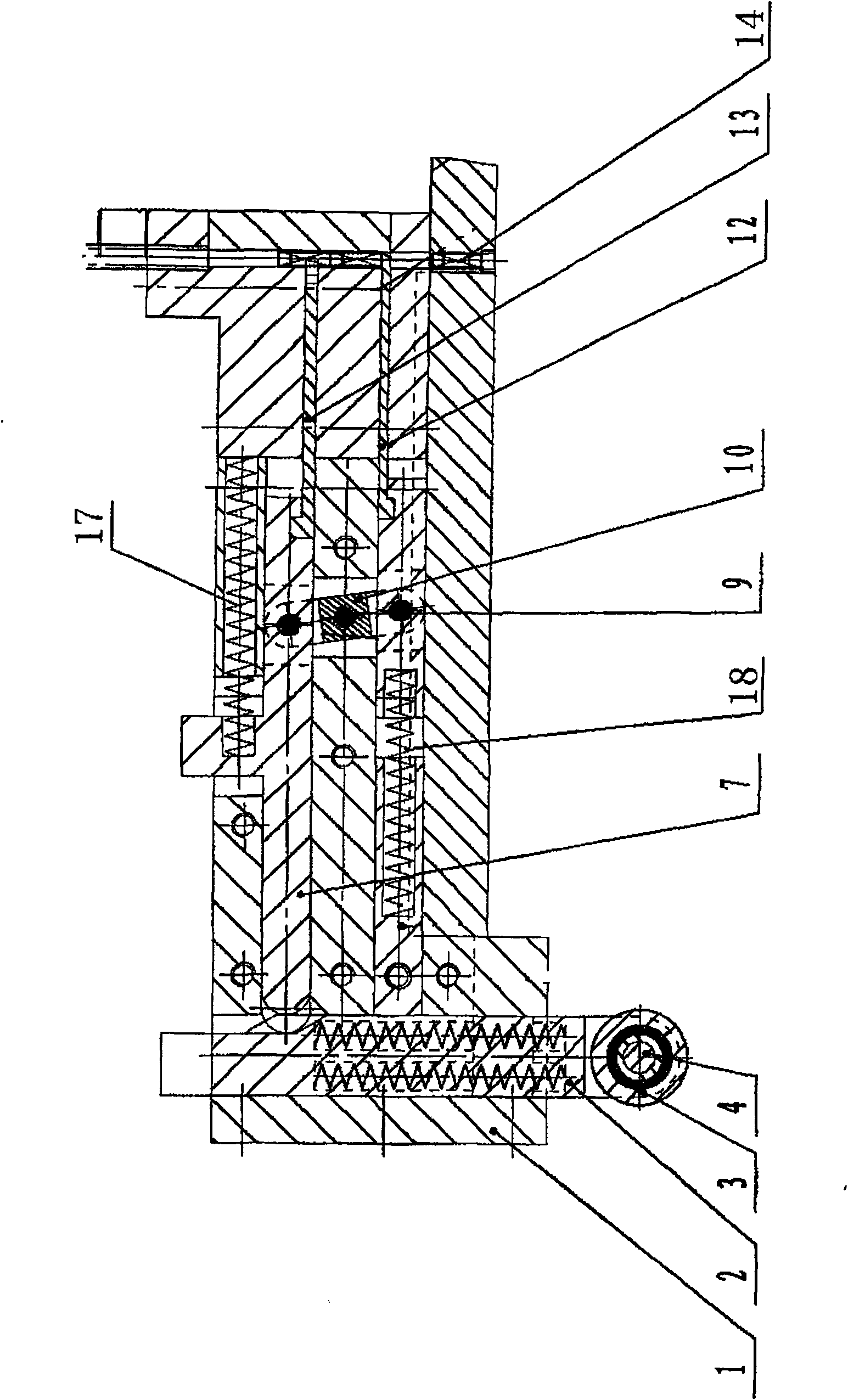

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0014] see figure 1 , a spray pump spring small bowl assembly machine spring delivery mechanism, including a frame 1, one end of the frame 1 is provided with a slide rail groove, there is a track plate 2 in the slide rail groove, and the track plate 2 is driven by a motor cam Driven by a needle bearing 3, the middle of the needle bearing 3 is fixed by a pin 4; the frame 1 also has a swing arm 10, and the middle of the swing arm 10 is connected to the frame 1 by a pin 9, and the swing arm 10 The two ends are connected with an upper sliding ruler 12 and a lower sliding ruler 13 through hinges, and the upper end of the swing arm 10 is also connected with an upper slider 7 touched by the track plate 2, and the upper and lower sliding rulers 12, 13 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com