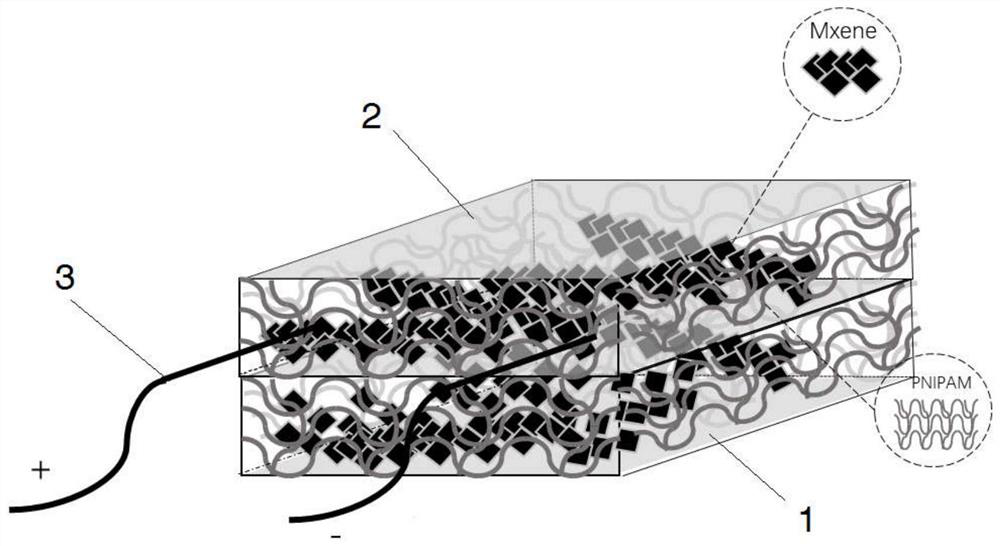

A preparation method of flexible temperature sensor based on composite thermosensitive hydrogel

A temperature-sensitive hydrogel and temperature sensor technology, applied in the field of sensors, can solve the problems of easy generation of temperature drift, increased integration difficulty and flexible circuit design difficulty, and achieve the effects of easy mass production, fast response and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing a flexible temperature sensor based on a composite thermosensitive hydrogel, comprising the following steps:

[0041] (1) Prepare two parts of NIPAM monomer solution: the first part mixes 0.5g NIPAM and 0.0175g BIS, add 4.3mL deionized water, stir well until the solution is clear and transparent; the second part mixes 0.5g NIPAM and 0.0175g BIS , add 4.7mL deionized water, stir well until the solution is clear and transparent;

[0042] (2) Add 0.7 mL of MXene monolayer colloid solution with a concentration of 5 mg / mL dropwise to the first NIPAM monomer solution, and stir slowly until uniform, so that the MXene content in the monomer solution reaches 0.7 mg / mL ; Add 0.3 mL of MXene monolithic colloid solution dropwise to the second NIPAM monomer solution with a concentration of 5 mg / mL, and slowly stir until uniform, so that the MXene content in the monomer solution reaches 0.3 mg / mL;

[0043] (3) Drop in 10uL of 10% APS solution and 10uL of TEMED...

Embodiment 2

[0049] A method for preparing a flexible temperature sensor based on a composite thermosensitive hydrogel, comprising the following steps:

[0050] (1) Prepare two parts of NIPAM monomer solution: the first part mixes 0.6g NIPAM and 0.022g BIS, add 4.2mL deionized water, stir well until the solution is clear and transparent; the second part mixes 0.6g NIPAM and 0.022g BIS, Add 4.6mL deionized water, stir well until the solution is clear and transparent;

[0051] (2) Add 0.8 mL of MXene monolayer colloid solution with a concentration of 5 mg / mL dropwise to the first NIPAM monomer solution, and stir slowly until uniform, so that the MXene content in the monomer solution reaches 0.8 mg / mL ; Add 0.4mL concentration of MXene monolithic colloid solution of 5mg / mL dropwise to the second part of NIPAM monomer solution, and slowly stir until uniform, so that the MXene content in the monomer solution reaches 0.4mg / mL;

[0052] (3) Drop in 30uL of APS solution with a mass concentration ...

Embodiment 3

[0058] A method for preparing a flexible temperature sensor based on a composite thermosensitive hydrogel, comprising the following steps:

[0059] (1) Prepare two parts of NIPAM monomer solution: the first part mixes 0.65g NIPAM and 0.024g BIS, add 4.1mL deionized water, stir well until the solution is clear and transparent; the second part mixes 0.65g NIPAM and 0.024g BIS, Add 4.5mL deionized water, stir well until the solution is clear and transparent;

[0060] (2) Add 0.9 mL of MXene monolayer colloid solution with a concentration of 5 mg / mL dropwise to the first NIPAM monomer solution, and stir slowly until uniform, so that the MXene content in the monomer solution reaches 0.9 mg / mL ; Add 0.5 mL of MXene monolithic colloid solution dropwise to the second part of NIPAM monomer solution with a concentration of 5 mg / mL, and slowly stir until uniform, so that the MXene content in the monomer solution reaches 0.5 mg / mL;

[0061] (3) Drop in 20uL of APS solution with a mass co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com