Escape method suitable for water gushing and mud gushing in karst tunnels

A tunnel and water gushing technology, which is applied in earth drilling, mining equipment, safety devices, etc., can solve the problems of inability to escape, escape passages cannot be connected, etc., and achieve the effect of simple structure, convenient construction, and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] An escape refuge system suitable for water and mud gushing in karst tunnels, comprising a main tunnel system and an auxiliary tunnel system, and an escape passage connecting the main tunnel system and the auxiliary tunnel system.

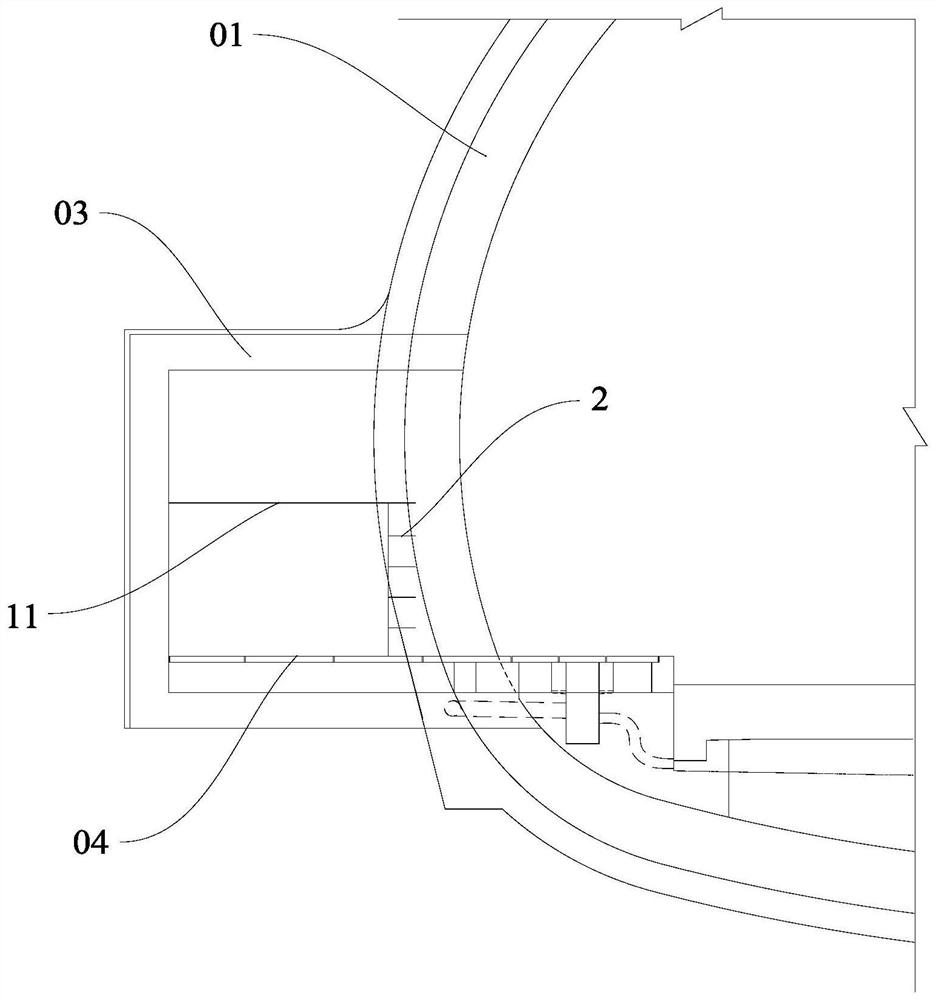

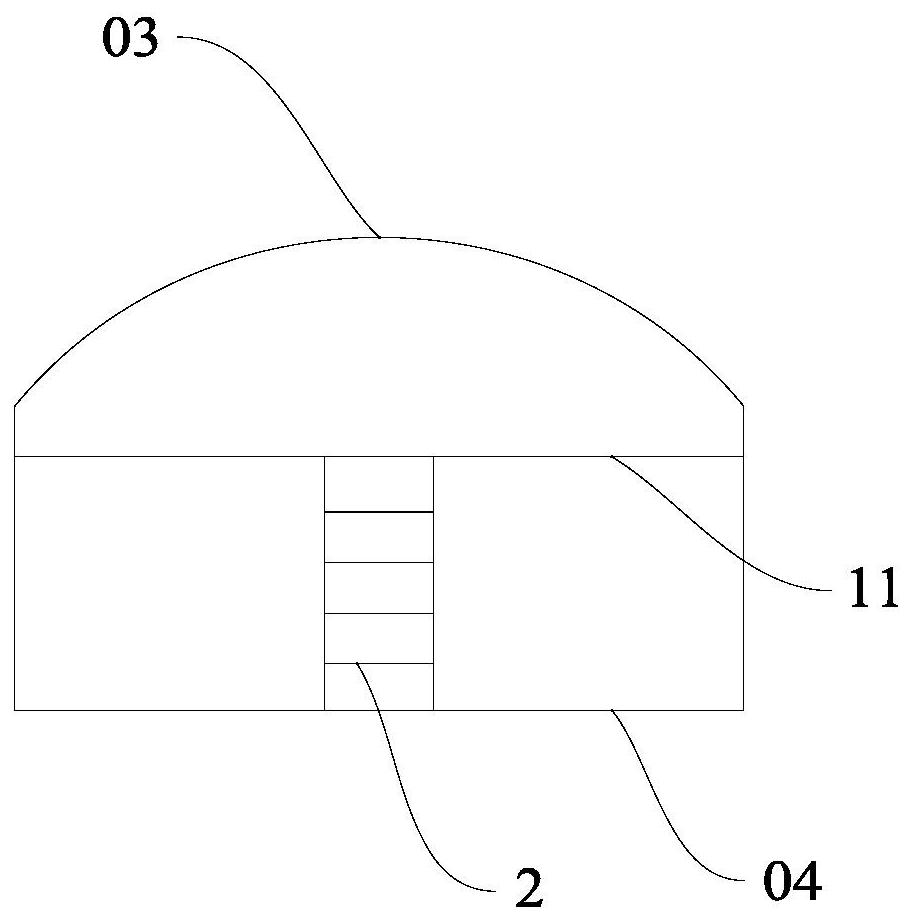

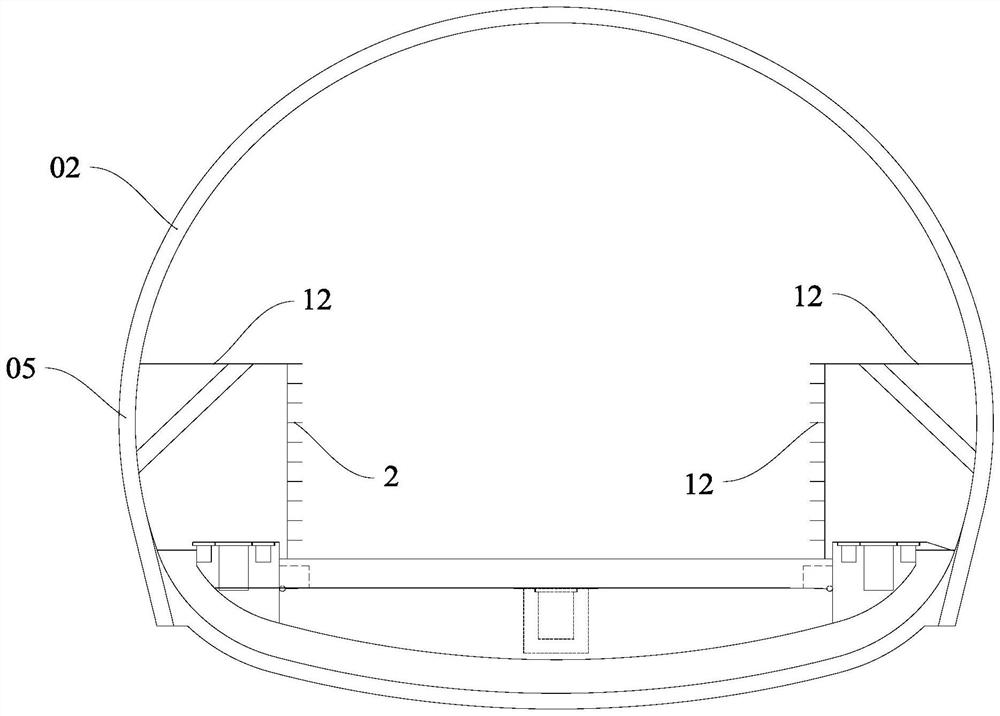

[0047] The main tunnel system includes an escape platform 1, and the escape platform 1 includes a first escape platform 11 arranged in the constructed cavern 03 of the normal tunnel section 01 with the second lining applied, and a first escape platform 11 arranged in the unapplied secondary lining tunnel section 01. The second escape platform 12 at the high position of the arch wall 05 of the main tunnel section 02.

[0048] Specifically, such as Figure 1-Figure 2As shown, the first escape platform 11 is set in the constructed cavern 03 of the second lining tunnel section 01, and the difference between the elevation of the first escape platform 11 and the elevation of the cave bottom 04 is greater than or equal to 1.5 m. The first escape p...

Embodiment 2

[0055] Such as Figure 9 As shown, an escape and refuge method suitable for water gushing and mud inrush in karst tunnels includes the following steps:

[0056] Step 1: Construction of an escape and refuge system suitable for water and mud inrush in karst tunnels as described in Example 1;

[0057] Step 2: When water and mud gushing occur in the main hole of the karst tunnel,

[0058] Escape personnel who are located in the main tunnel section 01 of the completed second lining enter the nearest constructed cavern 03 and use the ladder 2 to climb up to the first escape platform 11 to escape and seek refuge;

[0059] The escape personnel who are located in the main tunnel section 02 without the second lining use the ladder 2 to climb up to the second escape platform 12 located at the arch wall 05 to escape and take refuge.

[0060] When water and mud gushing occur in the auxiliary tunnel 06 of the karst tunnel,

[0061] Escape personnel located in section 07 of the through-pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com