Drainage filtering system suitable for steel structure building

A filter system and building technology, applied in waterway systems, buildings, drainage structures, etc., can solve problems such as sewer pipe blockage, filter blockage, time-consuming and labor-intensive problems, and achieve clean water flow, not easy to block, and reduce manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

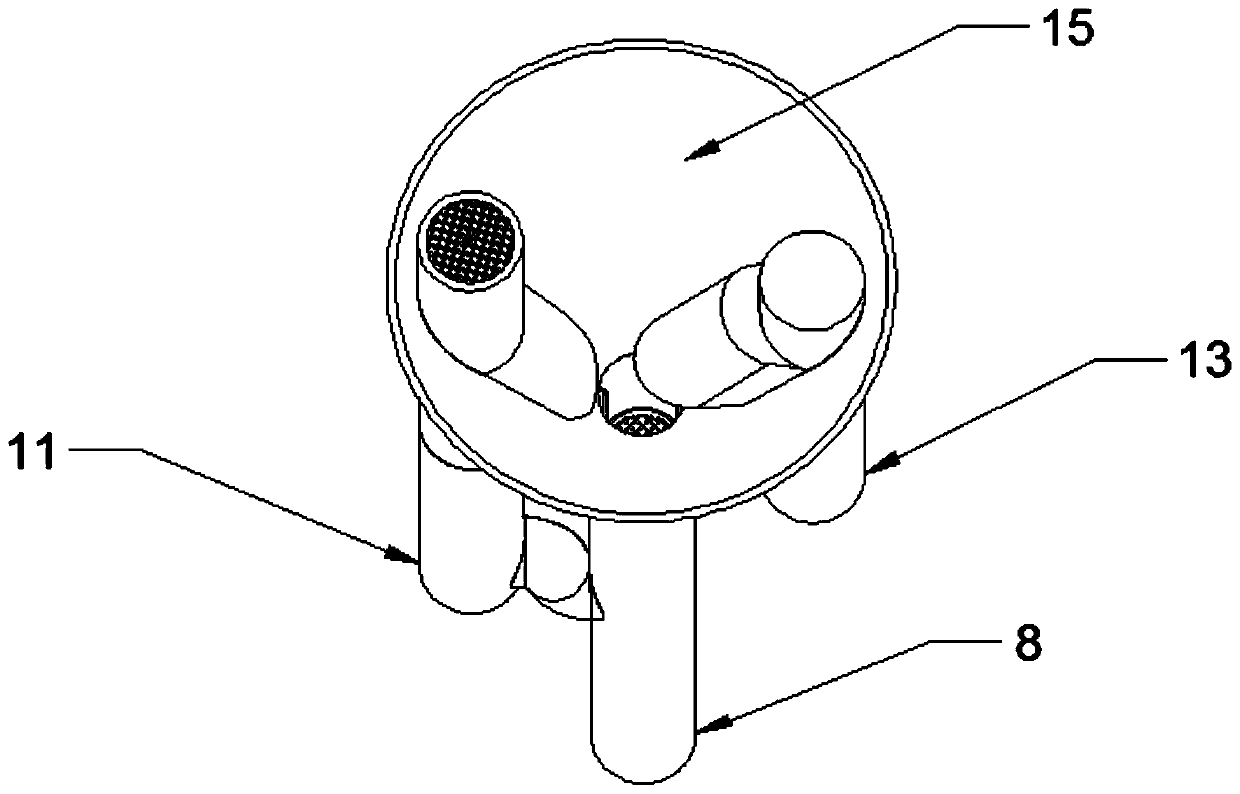

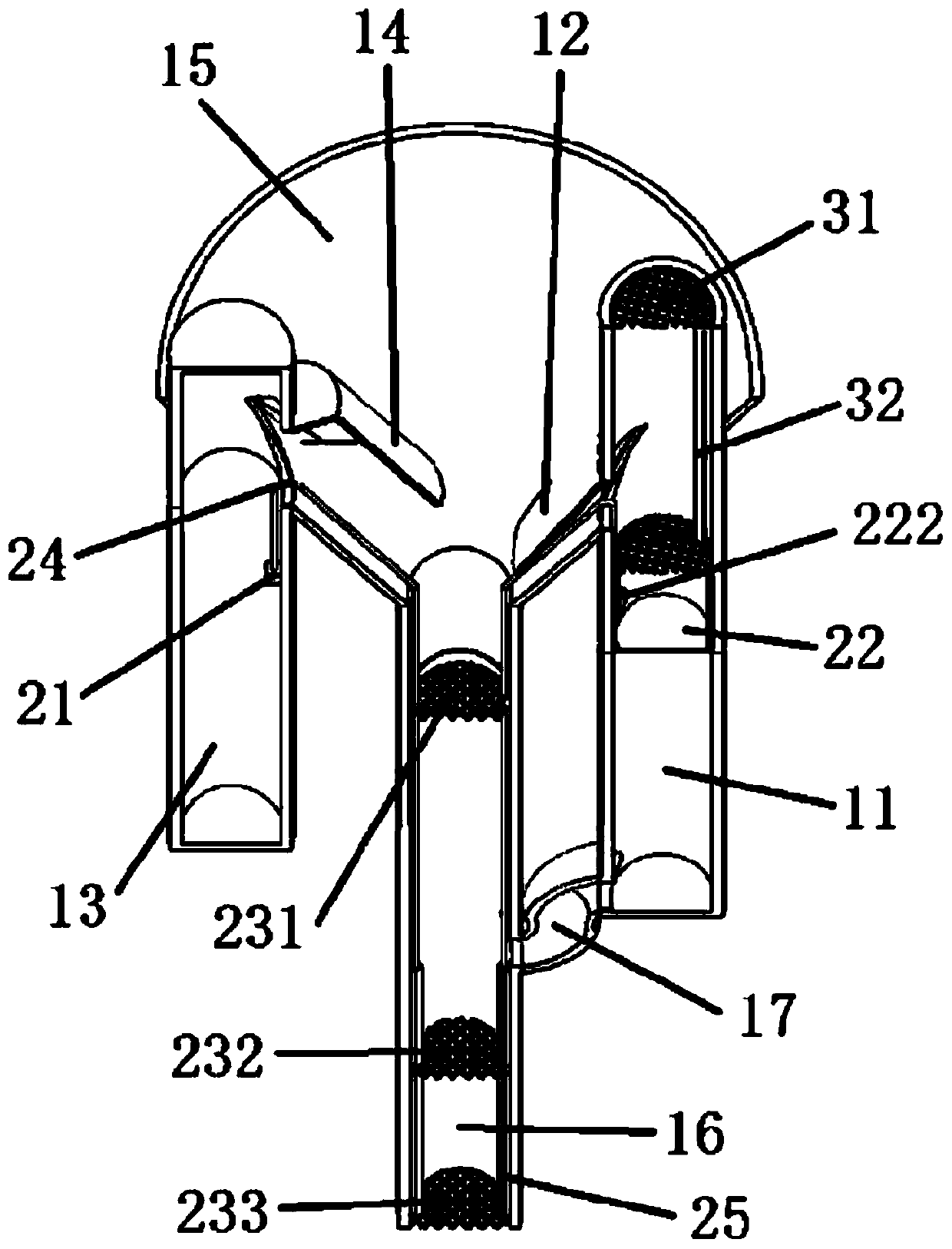

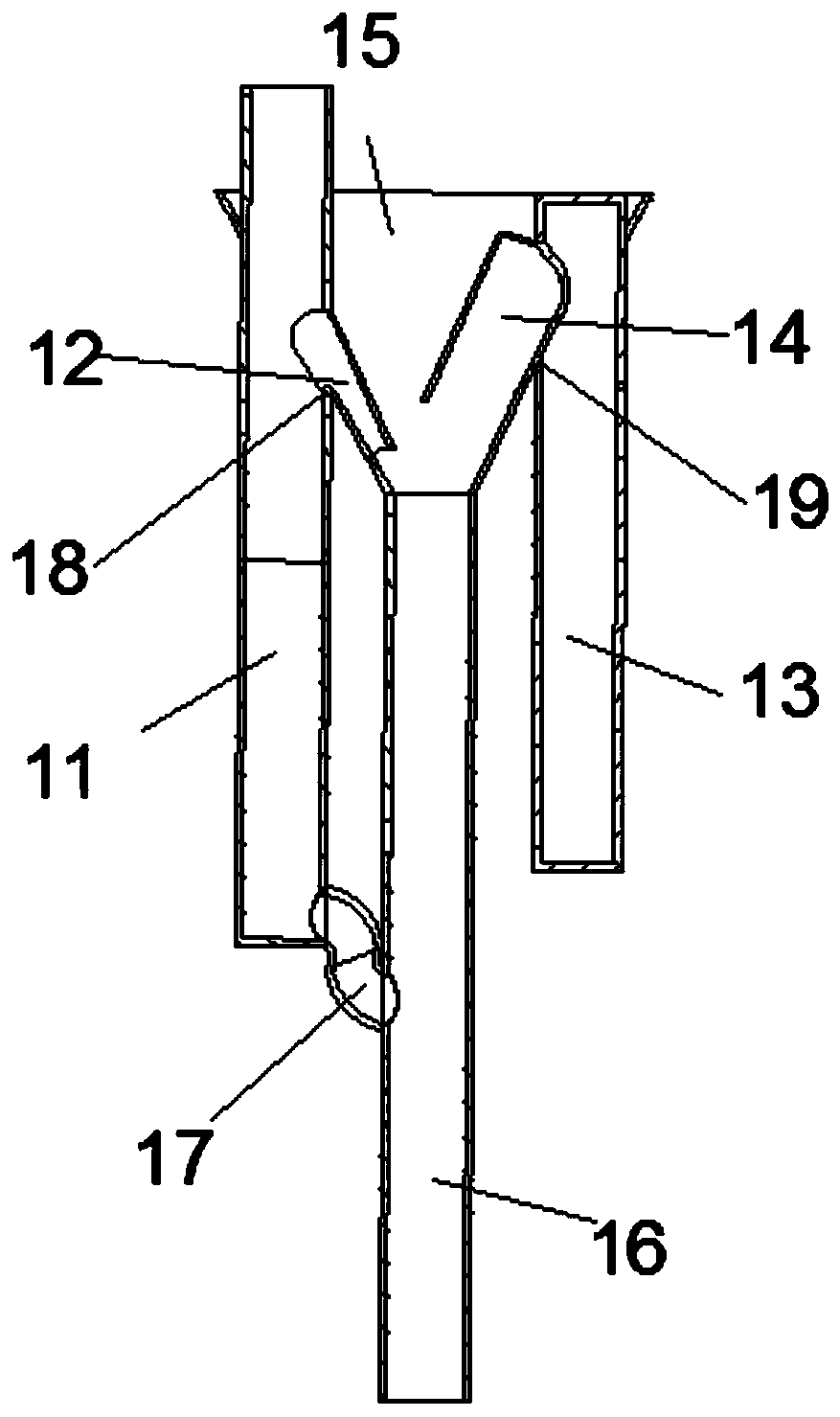

[0032] see Figure 1-Figure 6 As shown, the device is a drainage filtering system suitable for steel buildings. The present invention is divided into four devices, including a water guiding device 15, a first filtering device, a flood collecting device 11 and a filter residue collecting device 13, which relate to drainage In the field of filtration, it is widely used, and it is mainly suitable for drainage filtration of steel structures.

[0033] see Figure 2-Figure 4 As shown, the water guiding device has a water guiding groove with an opening facing upwards and a sewer pipe connected to the lower end of the water guiding groove. The first filtering device has a first filter screen 231, a second filter screen 232 and a third filter screen 233, and the first filter screen 231, the second filter screen 232 and the third filter screen 233 are successively arranged on the sewer pipe 16 along the vertical direction Inside, this filter structure can make the wastewater fully fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com