Composite temporary water retaining structure and construction method combining trd construction method diaphragm wall and earth-rock cofferdam

A technology of earth-rock cofferdam and water-retaining structure, which is applied in the direction of basic structure engineering, dams, sheet pile walls, etc., can solve the problems of high construction cost, great influence of steel price, and difficult quality assurance, so as to reduce the difficulty of demolition, prevent The advantage of seepage effect and the effect of improving the water blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

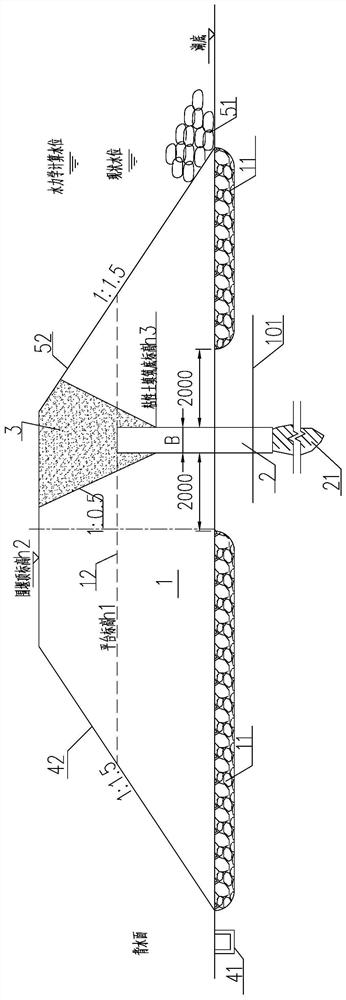

[0021] Refer to attached picture. The composite temporary water-retaining structure combined with the TRD construction method diaphragm wall and the earth-rock cofferdam provided by the present invention is composed of an earth-rock cofferdam 1, a TRD construction method diaphragm wall 2, and a cohesive soil filling area 3, and the TRD construction method diaphragm wall 2 is configured in The earth-rock cofferdam 1 is biased toward the upstream side. Concrete construction process of the present invention is as follows:

[0022] (1) Before the construction of the earth-rock cofferdam, remove the floating mud (0.5m thick) within the range of the weir foundation to ensure that the cofferdam is in contact with the river bed. In some areas, it is necessary to further stabilize the weir foundation by riprapping the silt. The reference number 11 is Rock riprap area (thickness 0.5m). The overall inclination angle of the contact surface should not be greater than 2°. In order to avo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com