Formaldehyde-free impregnating adhesive for decorative paper and preparation method thereof

A decorative paper and adhesive technology, used in special paper, papermaking, paper and other directions, can solve the problems of poor scratch resistance, high degree of cross-linking, inability to achieve gloss and fullness, and improve scratch resistance. performance, solve the damage between paper, improve the effect of glue hanging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

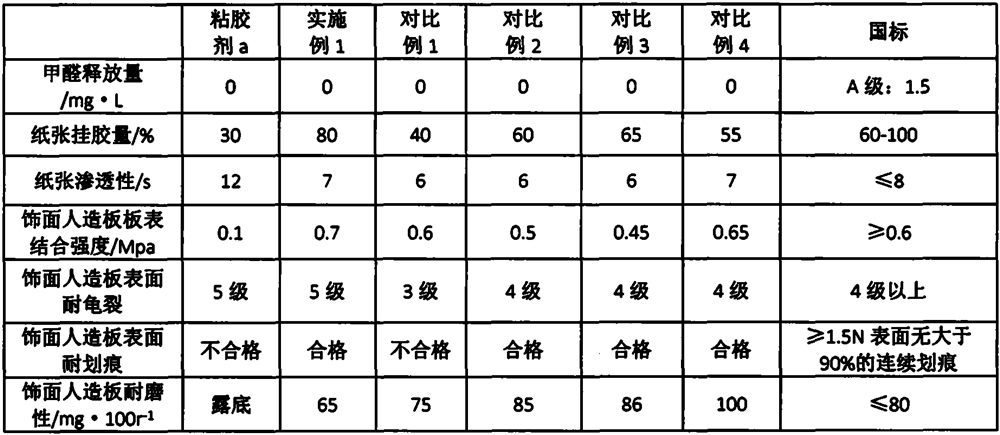

Examples

Embodiment 1

[0030] 1) Add all pH adjusters and deionized water, 1 / 3 soft monomer, 1 / 3 hard monomer, 1 / 3 initiator and all emulsifiers into the reactor, and the stirring paddle is at an angle of 50° to the horizontal plane. The height of the leaves from the bottom of the reaction vessel is 1 / 2 of the height of the liquid surface, the stirring speed is 200 r / min, and the reaction is stopped immediately after the blue light appears to prepare the pre-emulsion.

[0031] 2) Mix the remaining amount of soft monomer and hard monomer evenly, and add the remaining amount of initiator to the pre-emulsion dropwise at 85°C, and heat up to 85°C under stirring, with a stirring speed of 150r / min After 30min dripping, the stirring paddle was always kept at an angle of 50° with the horizontal plane during the dripping process, and the height of the paddle from the bottom of the reaction vessel was 1 / 2 of the liquid level height.

[0032] 3) A formaldehyde-free adhesive for decorative paper, according to t...

Embodiment 2

[0042] 1) Add all pH adjusters and deionized water, 1 / 3 soft monomer, 1 / 3 hard monomer, 1 / 3 initiator and all emulsifiers into the reactor, and the stirring paddle forms an angle of 60° with the horizontal plane. The height of the leaf from the bottom of the reaction vessel is 1 / 3 of the height of the liquid surface, the stirring speed is 150 r / min, and the reaction is stopped immediately after the blue light appears to prepare the pre-emulsion.

[0043] 2) Mix the remaining soft monomer and hard monomer evenly, and add the remaining amount of initiator dropwise to the pre-emulsion under the condition of 85 ℃, and heat up to 85 ℃ under stirring, and the stirring speed is 100r / min After 30min dripping, the stirring paddle was always kept at an angle of 60° with the horizontal plane during the dripping process, and the height of the paddle from the bottom of the reaction vessel was 1 / 3 of the liquid level height.

[0044] 3) A formaldehyde-free adhesive for decorative paper, acc...

Embodiment 3

[0054] 1) Add all pH adjusters and deionized water, 1 / 3 soft monomer, 1 / 3 hard monomer, 1 / 3 initiator and all emulsifiers into the reactor, and the stirring paddle is at a 50° angle to the horizontal plane. The height of the leaves from the bottom of the reaction vessel is 1 / 2 of the height of the liquid surface, the stirring speed is 180 r / min, and the reaction is stopped immediately after the blue light appears to prepare the pre-emulsion.

[0055] 2) Mix the remaining soft monomer and hard monomer evenly, add the remaining amount of initiator to the pre-emulsion dropwise at 85°C, and heat up to 85°C under stirring, with a stirring speed of 120r / min After 30min dripping, the stirring paddle was always kept at an angle of 50° with the horizontal plane during the dripping process, and the height of the paddle from the bottom of the reaction vessel was 1 / 2 of the liquid level height.

[0056] 3) A formaldehyde-free adhesive for decorative paper, according to the following formu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com