A kind of filter material ceramsite, processing system and processing method

A processing system and ceramsite technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve problems such as low drying efficiency, single drying method, and shortened sludge drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

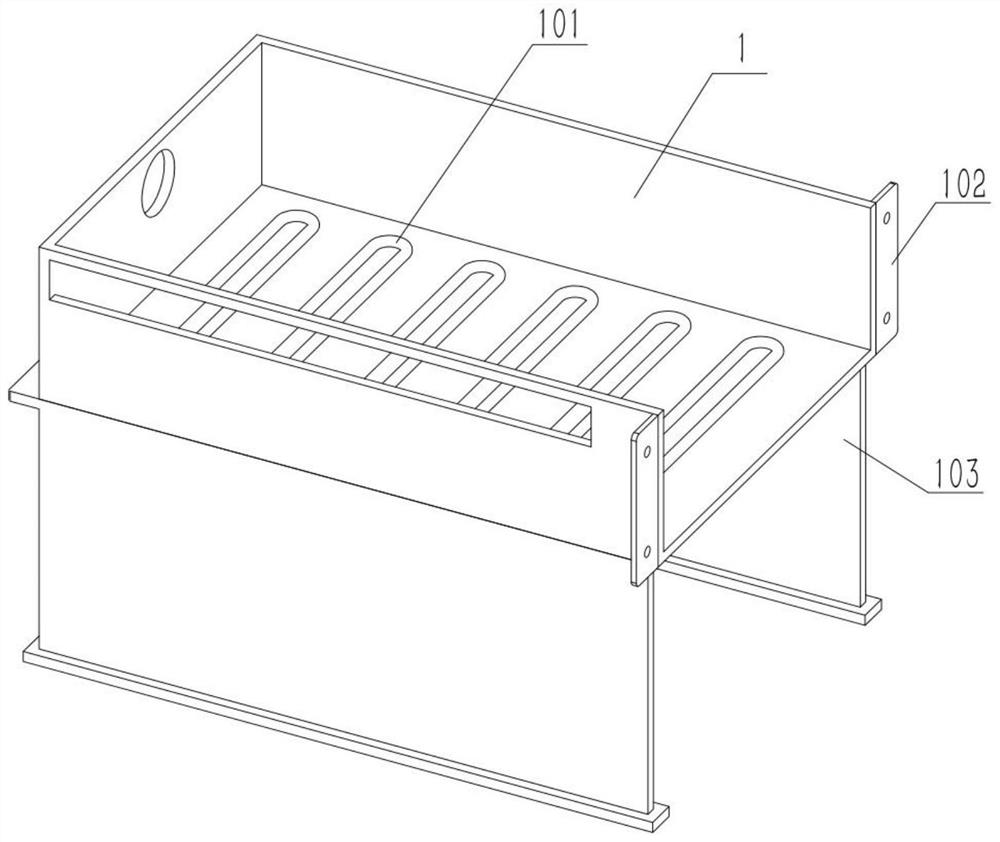

[0033] Such as Figure 1-8 As shown, a filter material ceramsite processing system includes a preliminary processing box 1, a base 103, a heating pipe 101, a heat conduction layer 104, and a fan 105. The primary processing box 1 is fixed on the upper end of the base 103, and the primary processing box 1 A heating pipe 101 is arranged on the inner bottom surface, a heat conducting layer 104 is fixedly connected in the primary processing box 1 and is located above the heating pipe 101 , and a blower fan 105 is installed on the side wall of the primary processing box 1 . The heating pipe 101 provides heat to the heat conduction layer 104 by means of resistive heating, and the heating pipe 101 can be purchased from existing products on the market. The material of the heat conduction layer 104 is preferably aluminum alloy, and the upper surface of the heat conduction layer 104 is used for laying mud, which is a mixture of water and soil. The blower fan 105 adopts an electric heati...

specific Embodiment approach 2

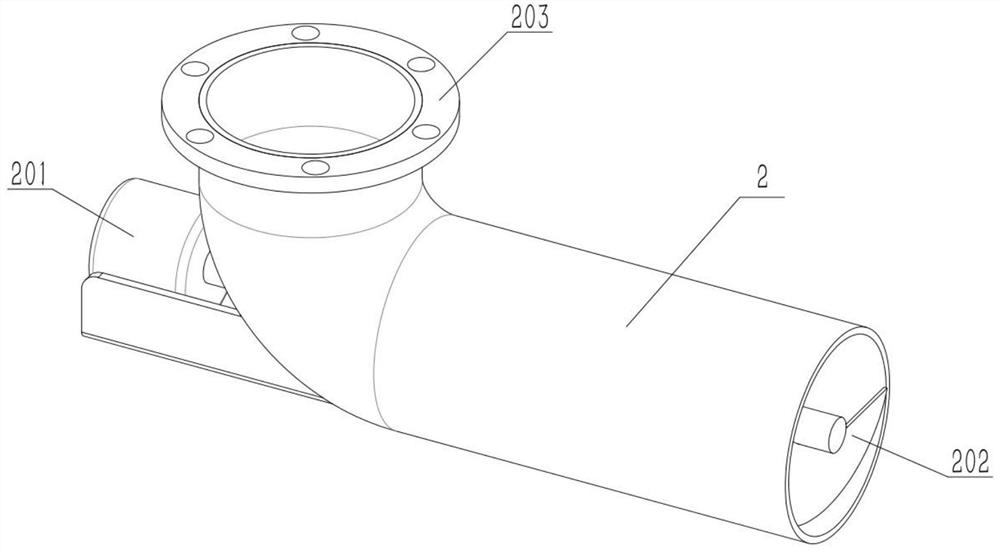

[0035] Such as Figure 1-8 As shown, this kind of filter material ceramsite processing system also includes a pipe 2, a motor I201, a spiral blade 202 and a flange 203. The pipe 2 is fixedly connected to and communicated with the left end of the primary processing box 1. 2, the output shaft of the motor I201 is connected to the pipe 2 in rotation, the output shaft of the motor I201 is located in the pipe 2, the screw blade 202 is fixed on the output shaft of the motor I201, and the flange 203 is fixed on the upper end of the pipe 2 . The motor I201 is started, and the output shaft of the motor I201 drives the screw blade 202 to rotate. Utilize flange plate 203 to connect pipe 2 with the pipeline that provides mud, and the spiral blade 202 that rotates is convenient to control the amount that mud releases in the initial processing box 1.

specific Embodiment approach 3

[0037] Such as Figure 1-8As shown, this filter material ceramsite processing system also includes a translation beam 3, a motor II 301, a gear 302, a rack 303, a side frame 304, a round steel 305, an electric telescopic rod I 306, a connecting plate 307, a base seat 4, a round Rod I 401, compression spring I 402, limit ring 403 and dial 404, the upper end of the translation beam 3 is fixedly connected to motor II 301, the output shaft of motor II 301 is fixed to gear 302, gear 302 is meshed with rack 303 for transmission, and rack The left and right ends of the 303 are fixedly connected to the two side frames 304 respectively, the front and rear sides of the translation beam 3 are respectively slidably connected to the two side frames 304, and the two ends of each round steel 305 are fixedly connected to the two side frames 304 respectively. On the frame 304, the electric telescopic rod I306 is affixed to the lower end of the translation beam 3, the connecting plate 307 is af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com