Rock wool insulation board wet blank cutting device and cutting method

A cutting device and a technology for plate wet blanks, which are applied in metal processing and other directions, can solve the problems affecting the cutting quality of wet blanks, increased energy consumption of curing furnaces, burrs, etc., and achieve the effects of simple structure, high degree of automation, and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

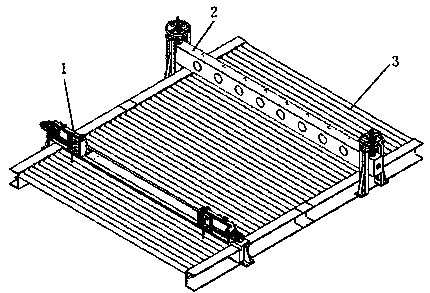

[0035] Embodiment 1 Rock wool insulation board wet billet cutting device

[0036] Such as figure 2 , image 3 As shown, the rock wool insulation board wet billet cutting device includes a gantry 1-14, and the gantry 1-14 is arranged across the transmission line 3.

[0037] The near left end and the near right end of the top surface of the gantry 1-14 are respectively provided with a cutting width adjustment unit and a high-pressure water jet cutting unit. The cutting width adjustment units at the left and right ends have the same structure and are arranged symmetrically.

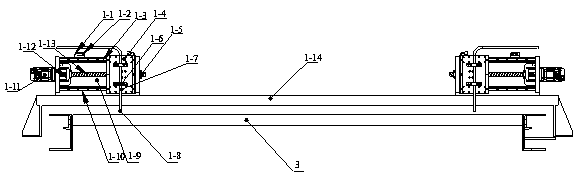

[0038] In the present embodiment, the cutting width adjustment unit includes a mounting seat 1-9, and an upper sliding rail 1-3 and a lower sliding rail 1-10 are arranged on the mounting seat 1-9; , Down rail 1-10 sliding connection.

[0039] The mounting base 1-9 is fixed with a servo motor 1-11, and the output shaft of the servo motor 1-11 is fixedly connected to one end of the lead screw 1-13 through...

Embodiment 2

[0043] Example 2 Rock wool insulation board wet billet cutting device

[0044] Compared with Embodiment 1, a limit switch for limiting the left and right sliding range of the slide plates 1-4 is added.

[0045] specifically:

[0046] Such as figure 2 , image 3 As shown, the limit switch mounting base 1-1 is installed on the mounting base 1-9, and the limit switch 1-2 is installed on the limit switch mounting base 1-1; the limit switch 1-2 is used to limit the slide plate 1-4 Left end sliding limit. A limit switch for limiting the sliding limit of the right end of the slide plate 1-4 and a mount (due to being blocked, not shown) for installing the limit switch are also installed on the right side of the mount 1-9.

[0047] In Embodiment 1 and Embodiment 2, the power mechanism for the horizontal sliding of the slide plate is a servo motor; it can also be an air cylinder or a hydraulic cylinder.

Embodiment 3

[0048] Embodiment 3 Rock wool insulation board wet billet automatic cutting system including the cutting device of embodiment 1 or embodiment 2

[0049]The applicant found in practice that "the water pressure, the thickness of the rock wool insulation board wet blank and the moving speed on the track will all affect the cutting quality of the wet blank."

[0050] At the same time, the inventor has found out how much line speed and water pressure correspond to the thickness of the material to ensure the cutting quality after numerous tests.

[0051] Some of the experimental results are shown in Table 1.

[0052] Table 1 Cutting quality corresponding to material thickness, line speed and water pressure

[0053]

[0054]

[0055]

[0056]

[0057]

[0058]

[0059] There are also some confirmatory test results, which will not be listed one by one. According to countless experiments, the parameters to ensure the cutting quality are obtained, as shown in Table 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com