Waste classification and environment-friendly treatment system

A technology for environmental protection treatment and garbage classification. It is used in grain treatment, solid separation, and separation of solids from solids by air flow. It can solve the problems of wasting time, affecting the efficiency of treatment, doping, etc., and achieves safe and convenient use. , Improve efficiency, scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

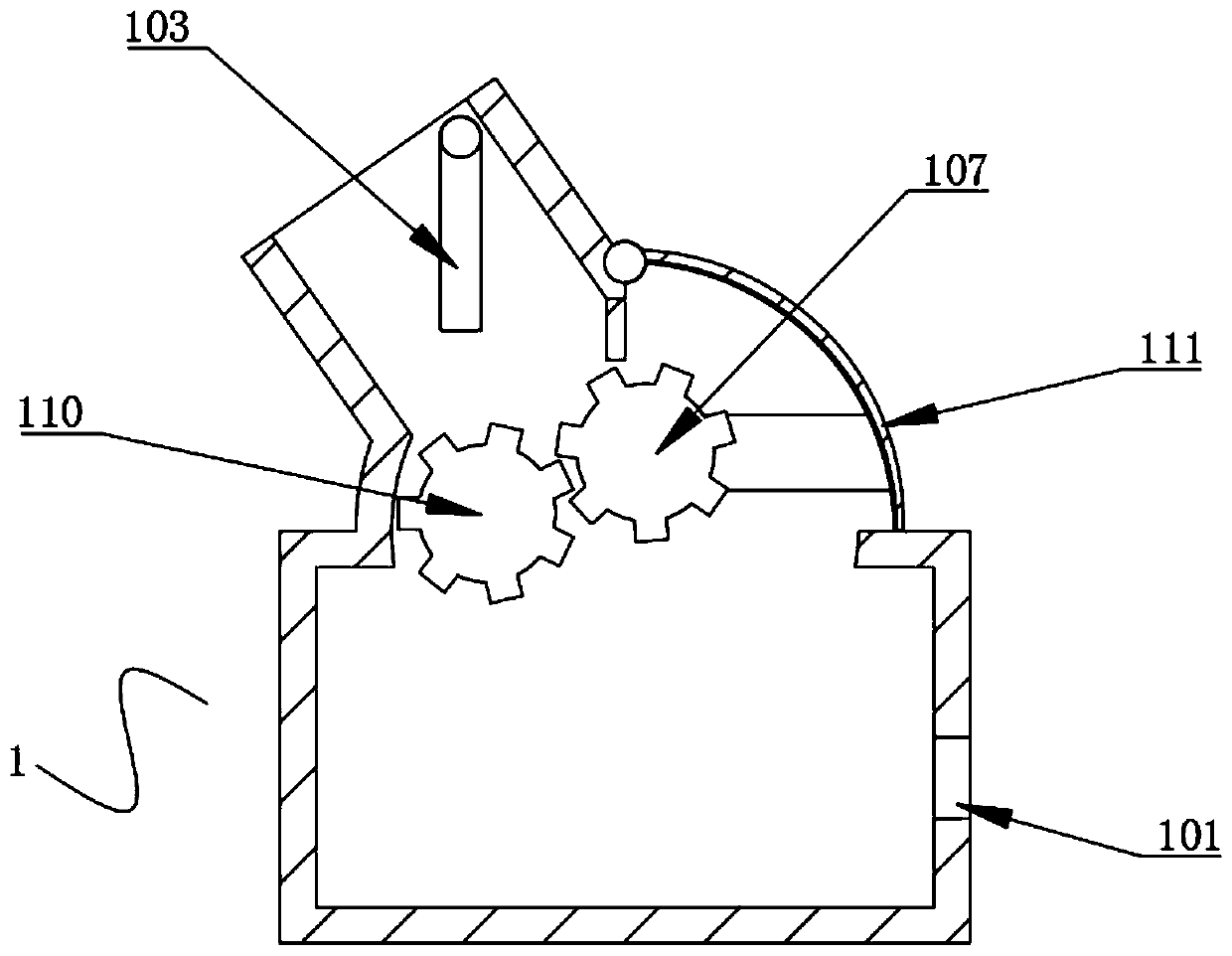

[0041] Example: such as Figure 1-8 As shown, the present invention provides a technical solution, a garbage sorting and environmental protection treatment system, including a pulverizer 1, a sorter 2, a filter screen 3, a dryer 4 and a conveyor belt 5, and the pulverizer 1, the sorter 2. The filter screen 3 and the dryer 4 are all connected by a conveyor belt 5, and the pulverizer 1 includes a pulverization box 101, a feed channel 102, a baffle 103, a knob 104, a chute 105, a slider 106, and a first pulverization roller 107 , limit plate 108, bolt 109, second crushing roller 110, cover plate 111 and driving motor 112;

[0042]The top of the crushing box 101 is fixedly connected with a feed channel 102, and the side position of the inner wall of the feed channel 102 is rotatably connected to a baffle plate 103. Width, the width of the baffle plate 103 is equal to the width of the feed channel 102, the position of the corresponding baffle plate 103 at both ends of the feed cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com