Plasma arc magnetic rotary gasification pulverizing furnace

A plasma and magnetic technology, applied in the field of powder metallurgy, can solve the problems of reducing the production capacity of the gasification pulverizing furnace, reducing the uniformity of product particle size, and reducing product quality, so as to achieve product quality and production stability, energy concentration, and improvement The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

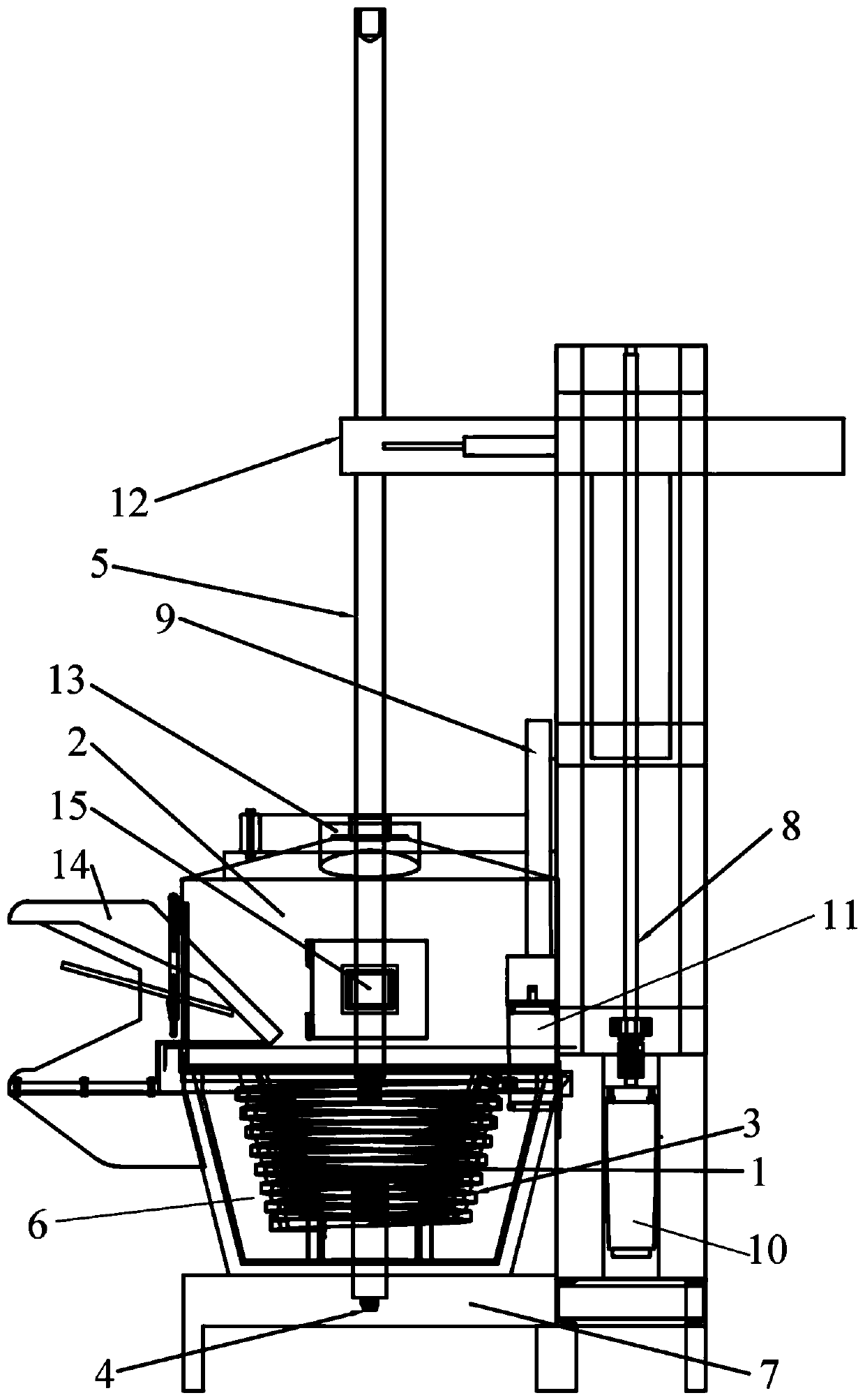

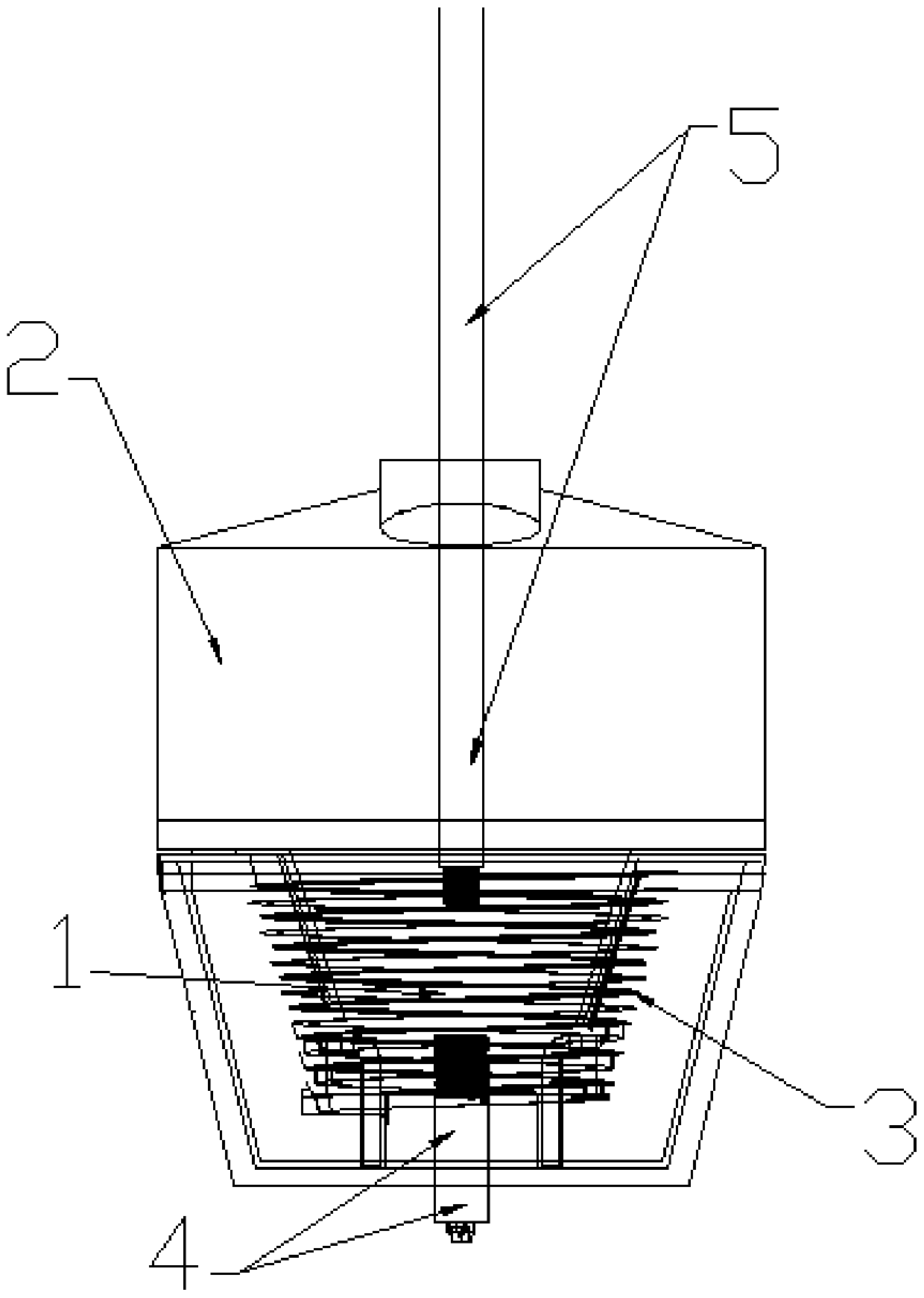

[0041] As a kind of plasma arc magnetic rotary gasification pulverizing furnace of the embodiment of the present invention, such as figure 1 and figure 2 As shown, it includes a crucible 1, a dust collection cover 2, a magnetic coil 3, a first electrode 4, a second graphite electrode 5, a DC voltage output device and an exhaust device;

[0042]The dust collection cover 2 is connected with the pipeline of the exhaust device, the shape of the dust collection cover 2 is a concave cover shape, the dust collection cover 2 is arranged on the opening side of the crucible 1, and there is a gap between the dust collection cover 2 and the opening of the crucible 1 , the concave side of the dust collection cover 2 faces the opening of the crucible 1, the first electrode 4 and the second graphite electrode 5 are at a certain distance, and the first electrode 4 and the second graphite electrode 5 are arranged on the concave side of the dust collection cover 2 In the space surrounded by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com